Method for production of inorganic nanofibres through electrostatic spinning

a technology of electrostatic spinning and nanofibres, which is applied in the direction of electro-spinning, electrical equipment, artificial filaments of inorganic materials, etc., can solve the problem that the known solutions used for electrostatic spinning of anorganic nanofibres cannot be used for continual production of nanofibres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

OF EMBODIMENT

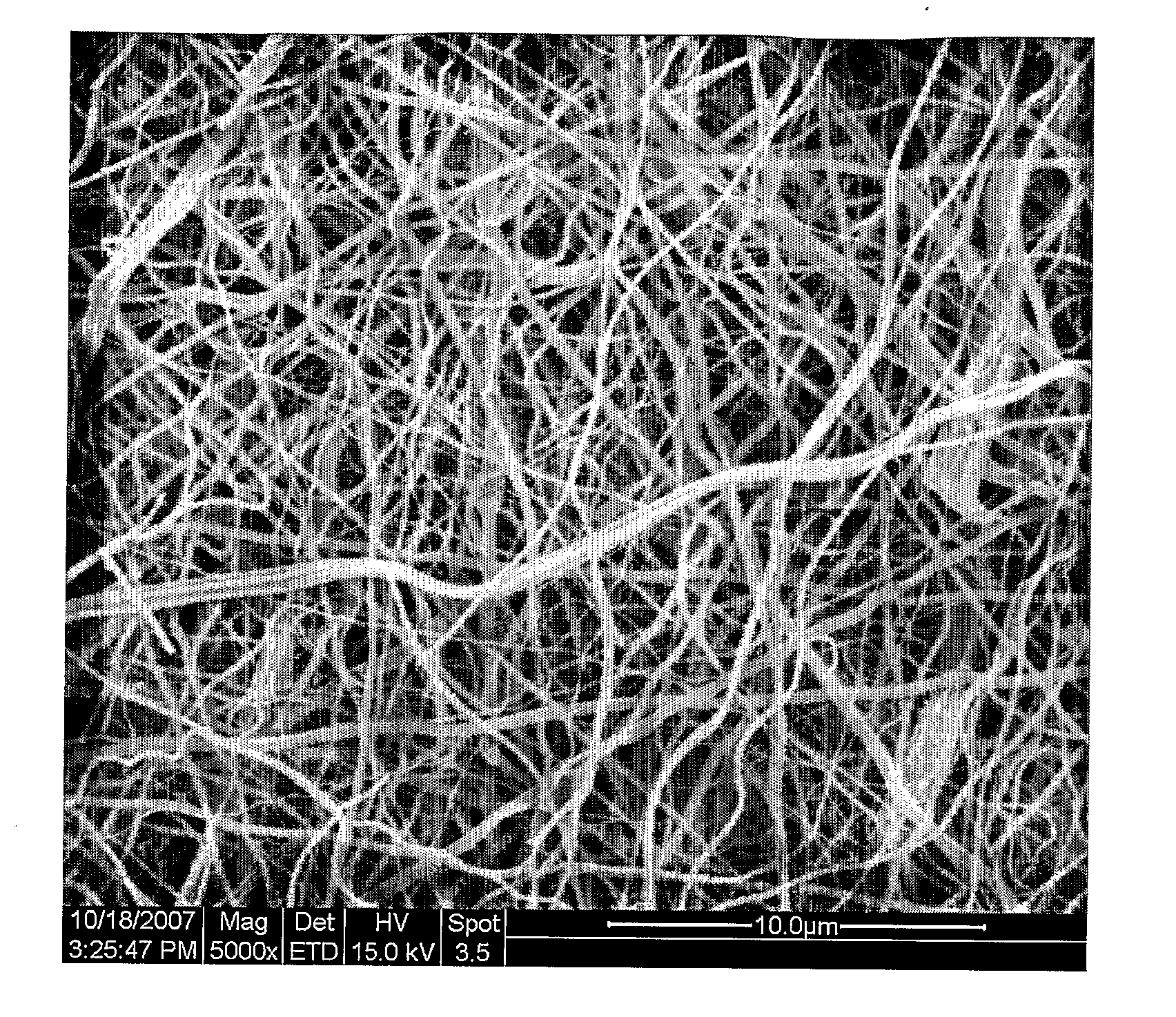

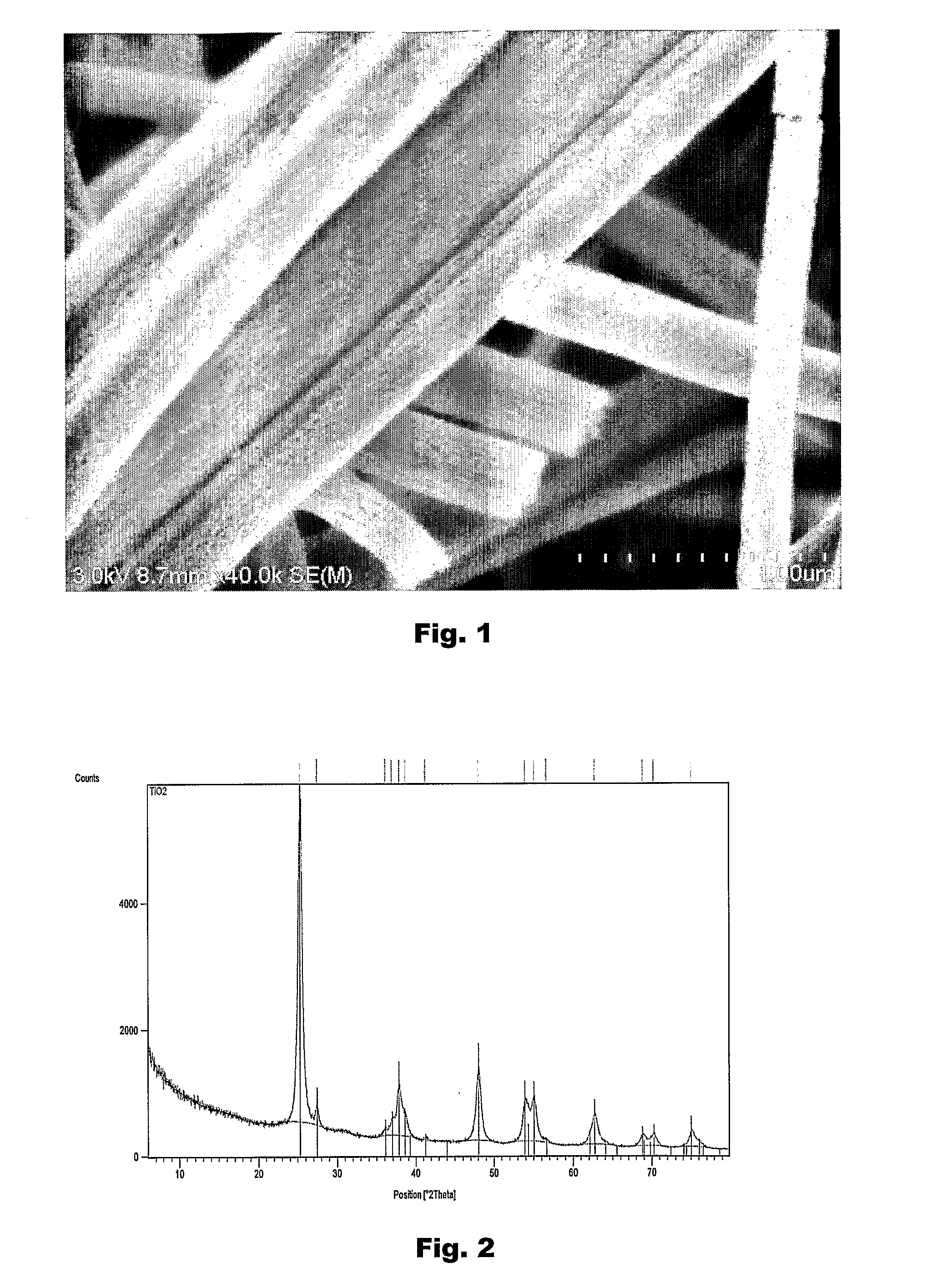

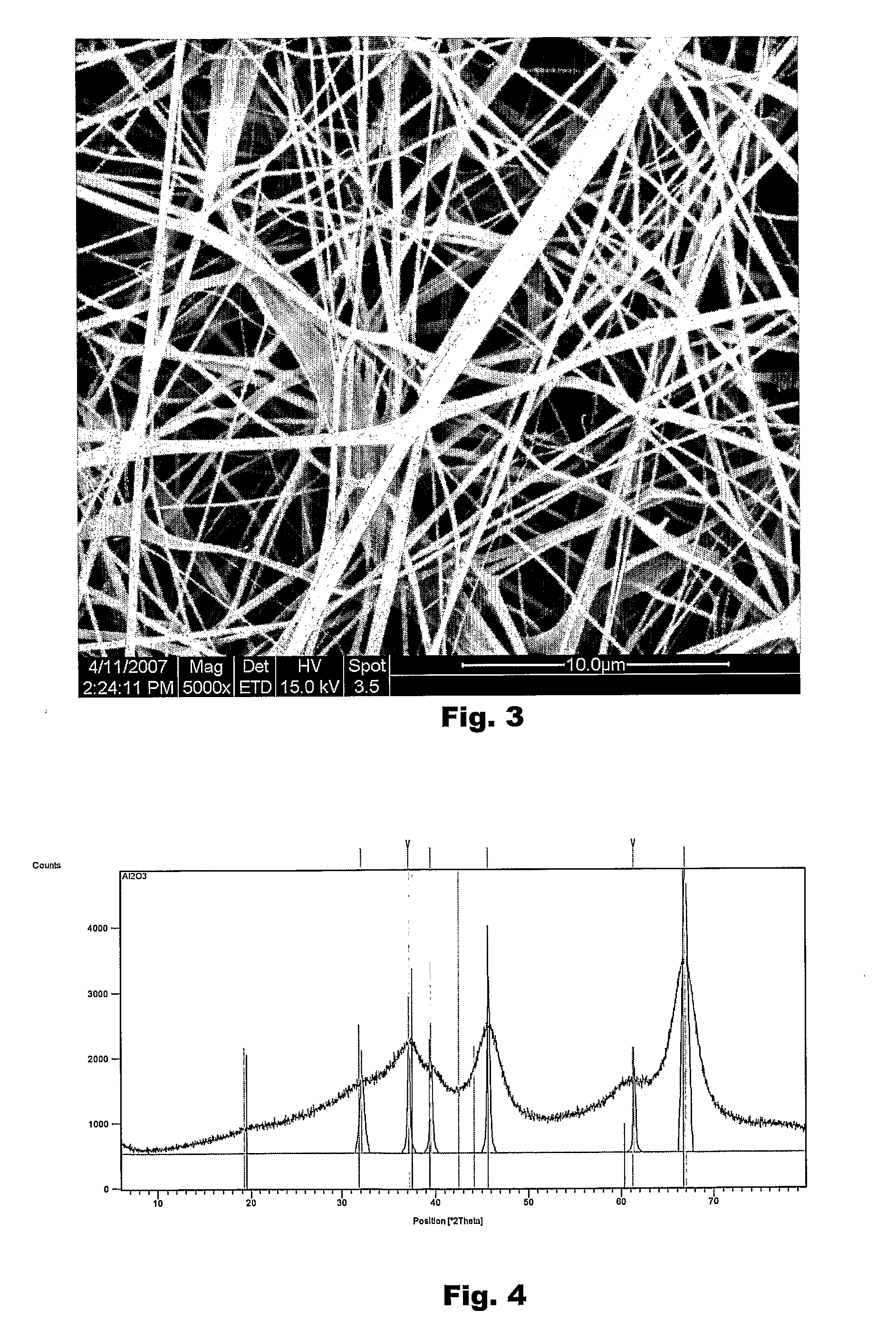

[0020]Spinning solution for production of inorganic nanofibres, especially of TiO2, SiO2, Al2O3, ZrO2 and B2O3, by means of electrostatic spinning contains as a source of inorganic basis an alkoxide of respective metal, semi-metal or non-metal, which is dissolved in a suitable solvent, e.g. in ethanol, 1-propanol or 2-propanol. To stabilise the solution of alkoxide, especially to prevent its hydrolysis, an addition of chelating agent as stabiliser is necessary. The most suitable chelating agent is 6-diketone, e.g. acetylaceton. Molecular ratio between alkoxide and chelating agent should be within the range from 1:0.8 to 1:2.2. To improve the spinning ability of the solution also supporting polymer is added into it, which may be represented by e.g. poly(vinylpyrrolidone) having molecular weight of 1300000 g / mol or viscosity number K-90, while its weight concentration towards a total weight of solution is from 4 to 9% by weight.

[0021]The process of electrostatic spinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com