Control system for reel mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

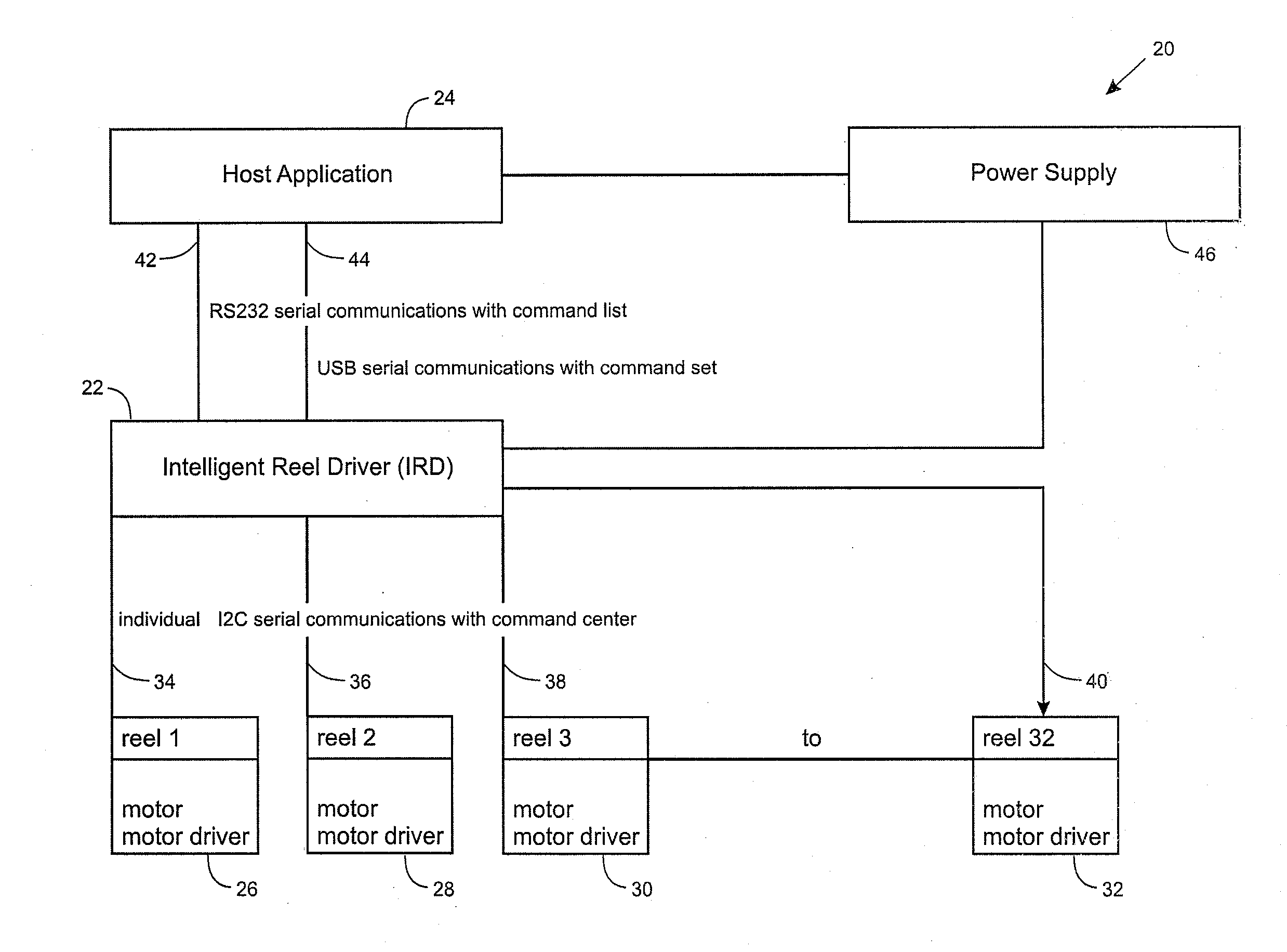

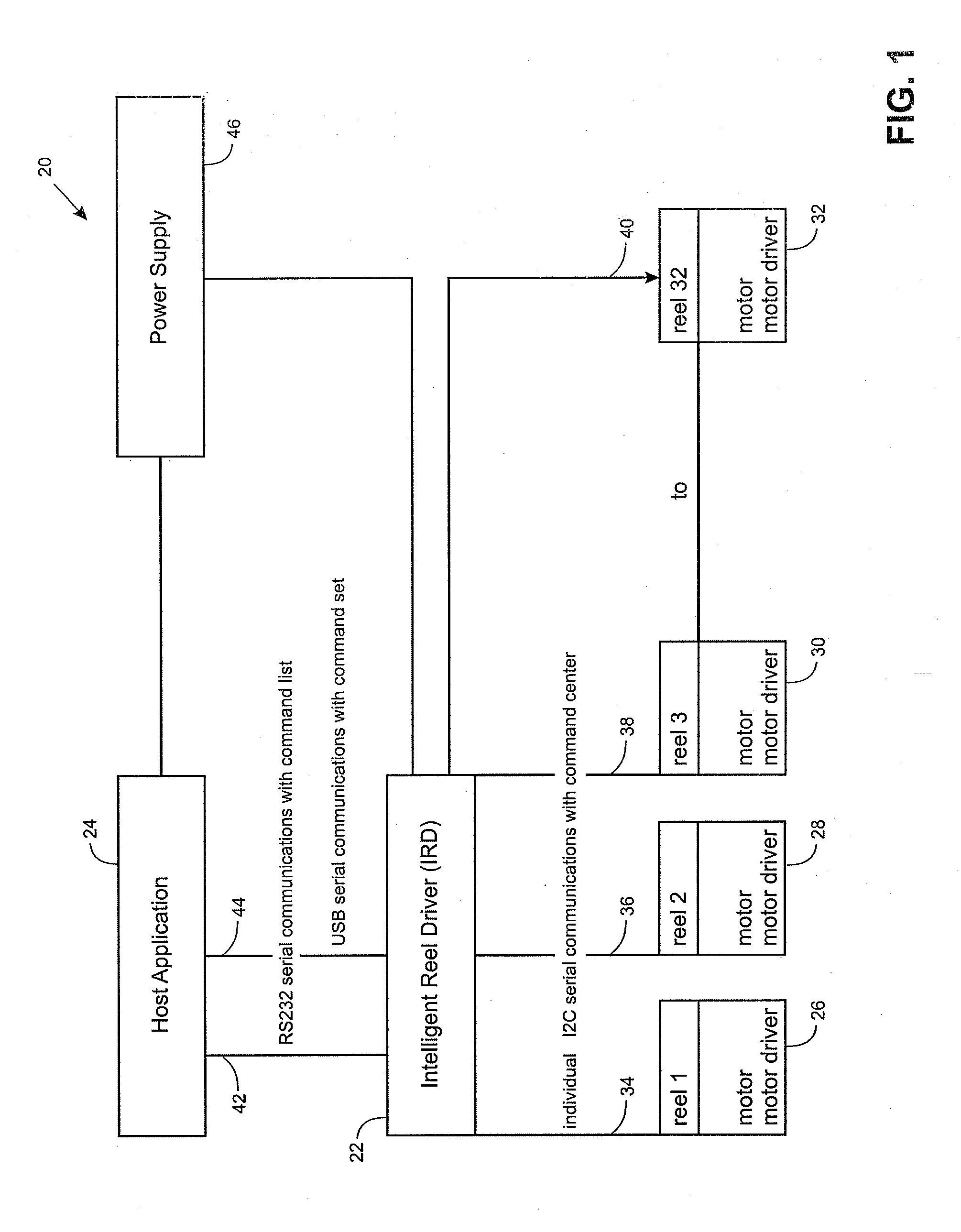

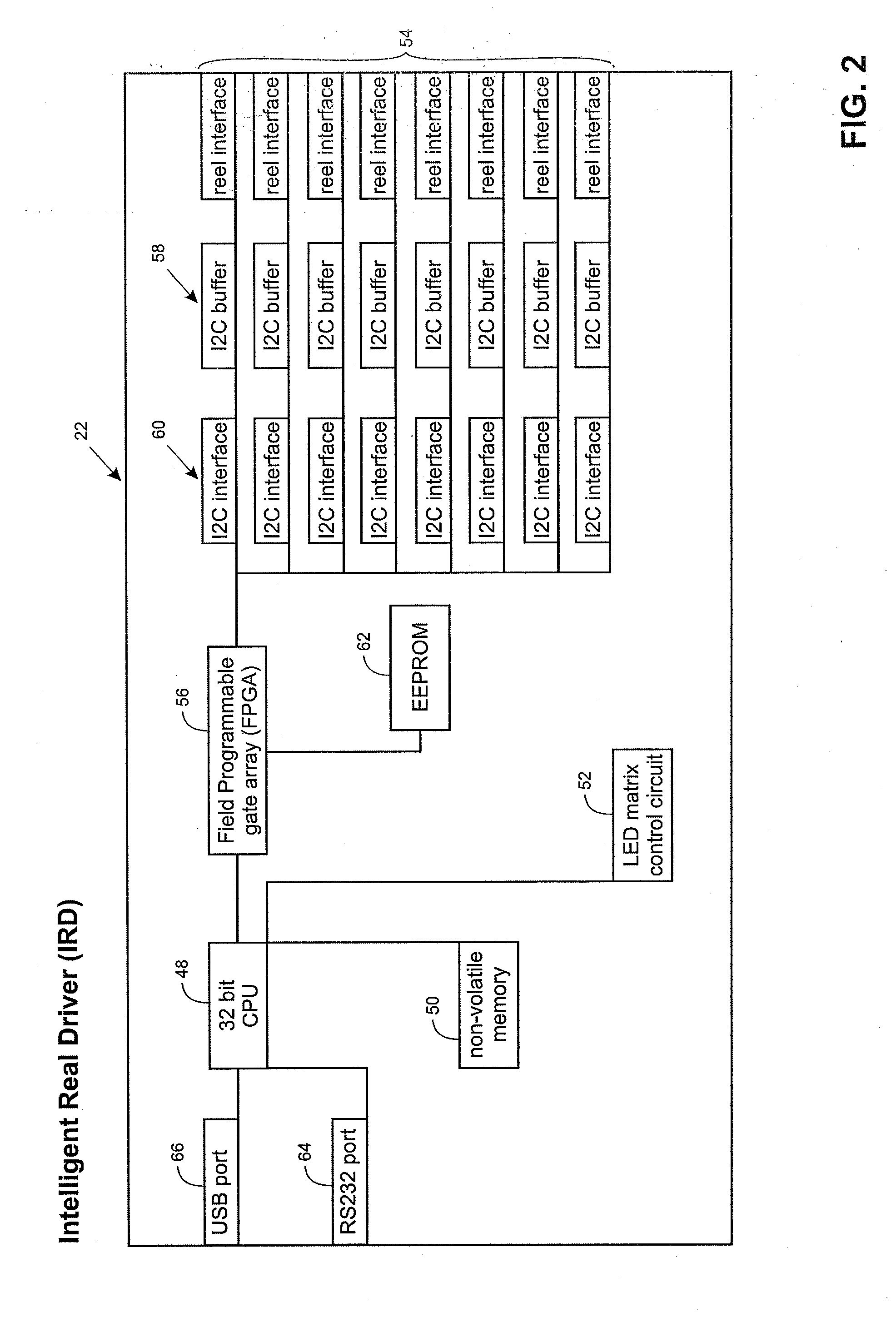

[0030]The present invention relates to a reel control system for a gaming machine having at least one reel mechanism, for example, as described in detail in U.S. Pat. Nos. 4,410,178 and 5,388,829, hereby incorporated by reference. As will be discussed in detail below, the control system in accordance with the present invention relates to a reel control system that includes various improvements relative to known reel control systems.

[0031]For example, the reel control system is configured to eliminate known problems related to phase setting and detection of reel movement during a standstill condition. In accordance with another aspect of the invention, the reel control system may also be configured to enable reels with unequal symbol lengths to be utilized which enabled the odds of a winning combination to be easily changed. In accordance with yet another aspect of the invention, the reel control system is configured to control multiple stepper motor drivers by way of a single serial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com