Catalyst for reducing mercury, a mercury conversion unit, and an apparatus for measuring total mercury in combustion exhaust gas by using the same

a technology of conversion unit and catalyst, which is applied in the direction of colloidal chemistry, instruments, separation processes, etc., can solve the problems of hardly feasible with the conventional apparatus for measuring total mercury, continuous measurement with catalyst performance maintained without, etc., and achieves high reducing function, high accuracy and stability. , the effect of high reducing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

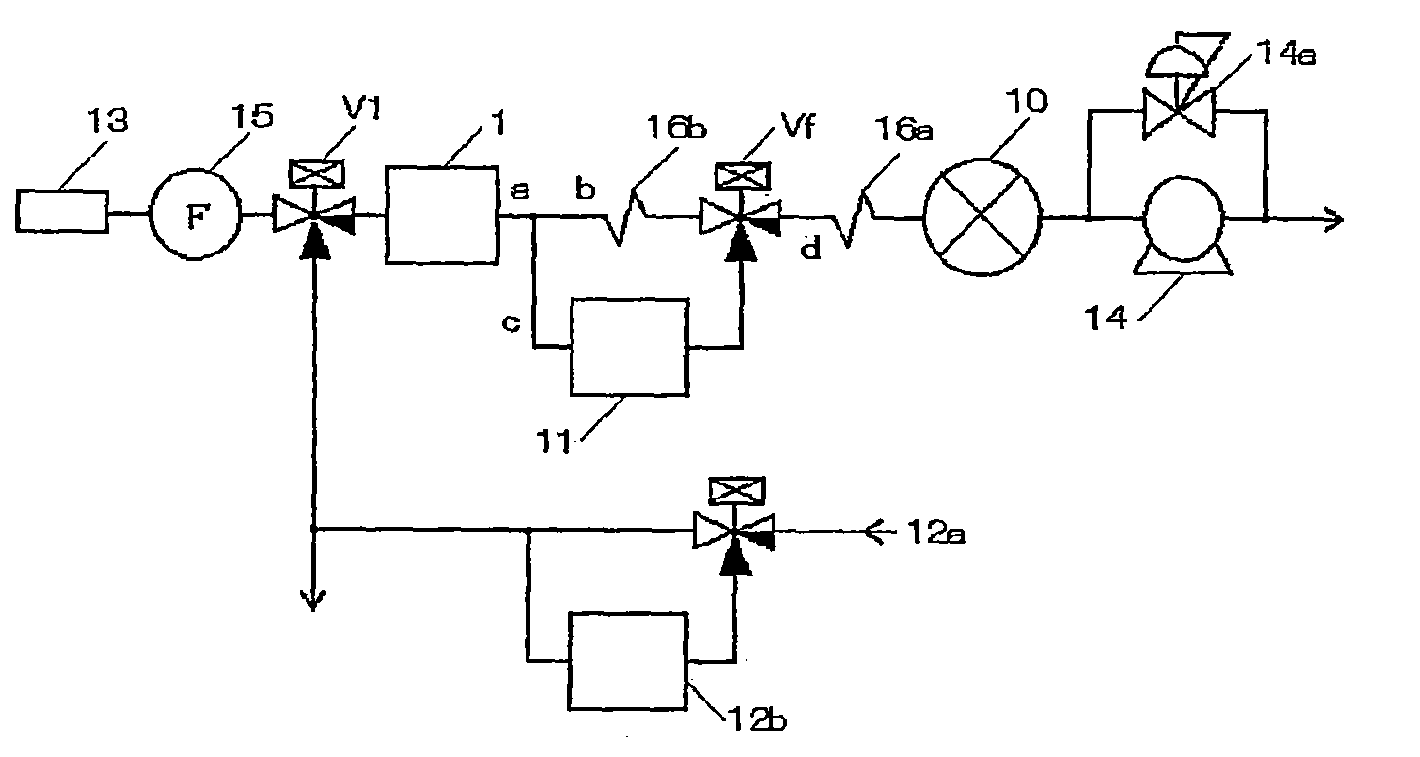

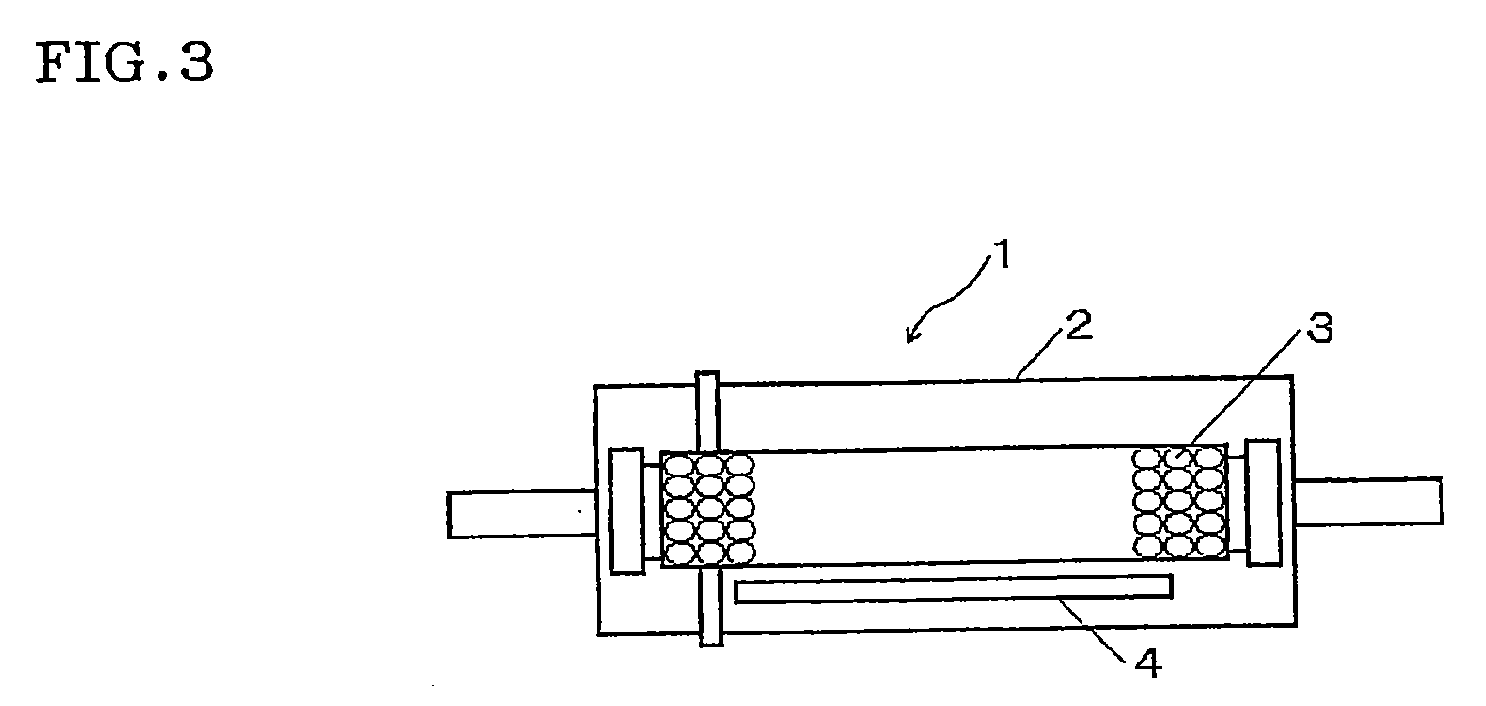

[0043]Hereinafter, embodiments of the present invention are described in more detail by reference to the Drawings.

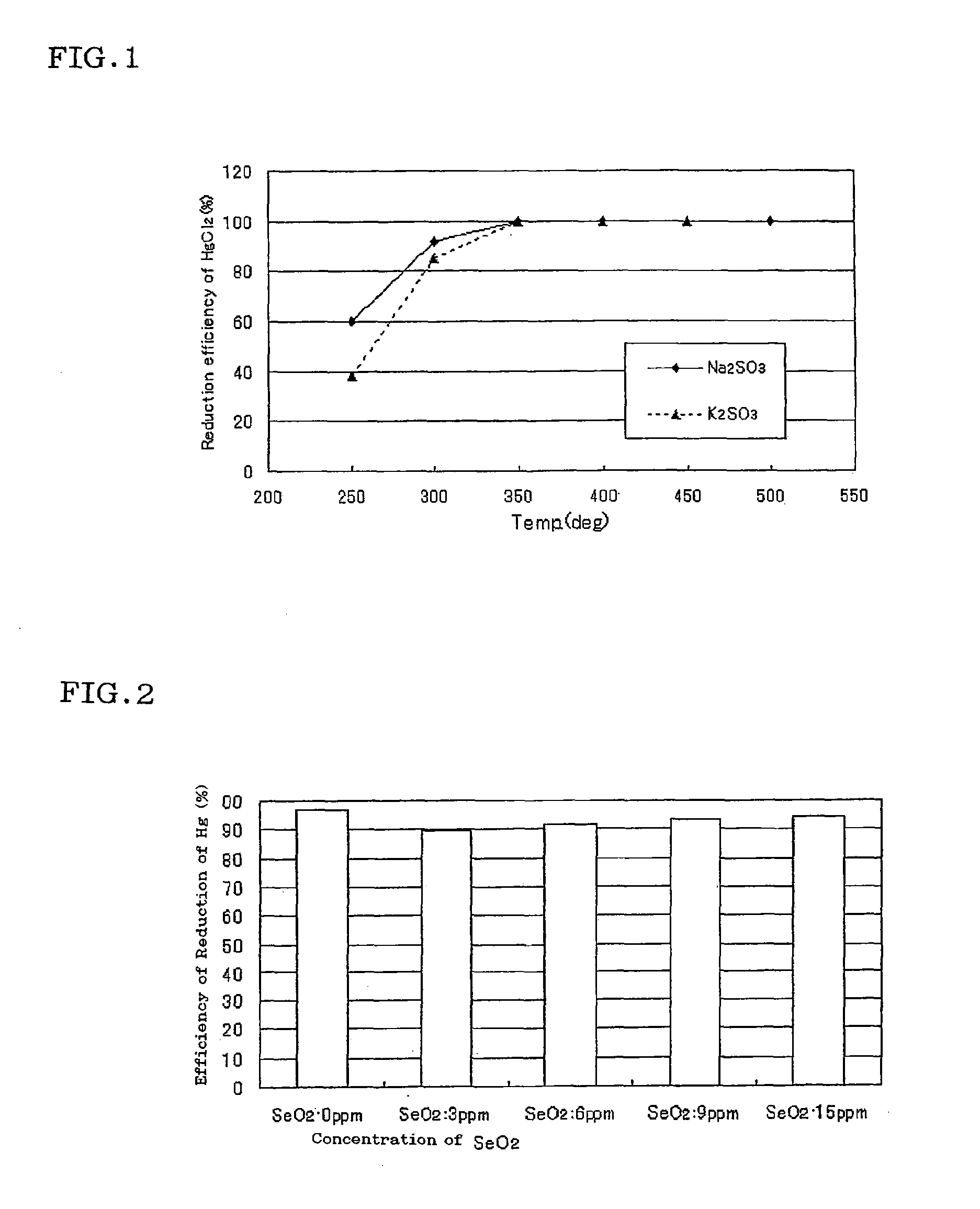

[0044]

[0045]The fundamental constitution of the mercury reduction catalyst according to the present invention is that the reagent of the present invention (corresponding to “a reagent comprising any of the sulfites of potassium, sodium, calcium and magnesium, or any of the phosphates thereof, or a combination of them”) is contained as a main reagent of the catalyst component. That is, the reagent of the present invention exerts reducing action selectively on a mercury compound (bifunctional) to covert it into element mercury, by utilizing the unique characteristics: (A) selectivity of reducing catalyst action for a mercury compound (bifunctional) and (B) unreactivity with coexisting acidic substances. The reagent of the present invention is poor in (C) reactivity with acidic substance such as SO2 and NO2, to eliminate the poisoning action thereof on the catalyst (poisoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| operative temperature | aaaaa | aaaaa |

| operative temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com