Electrostatic atomizing device and air conditioner using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

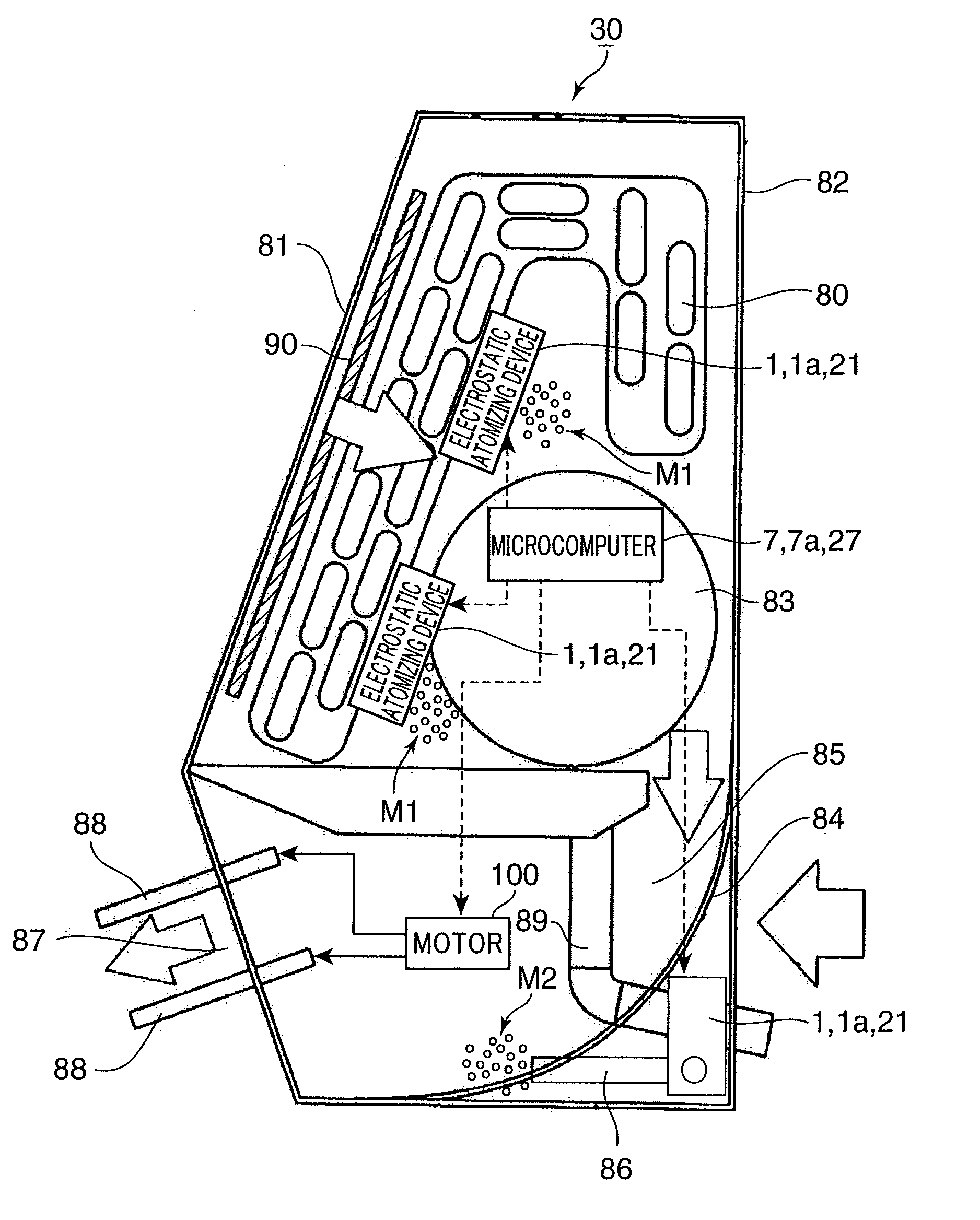

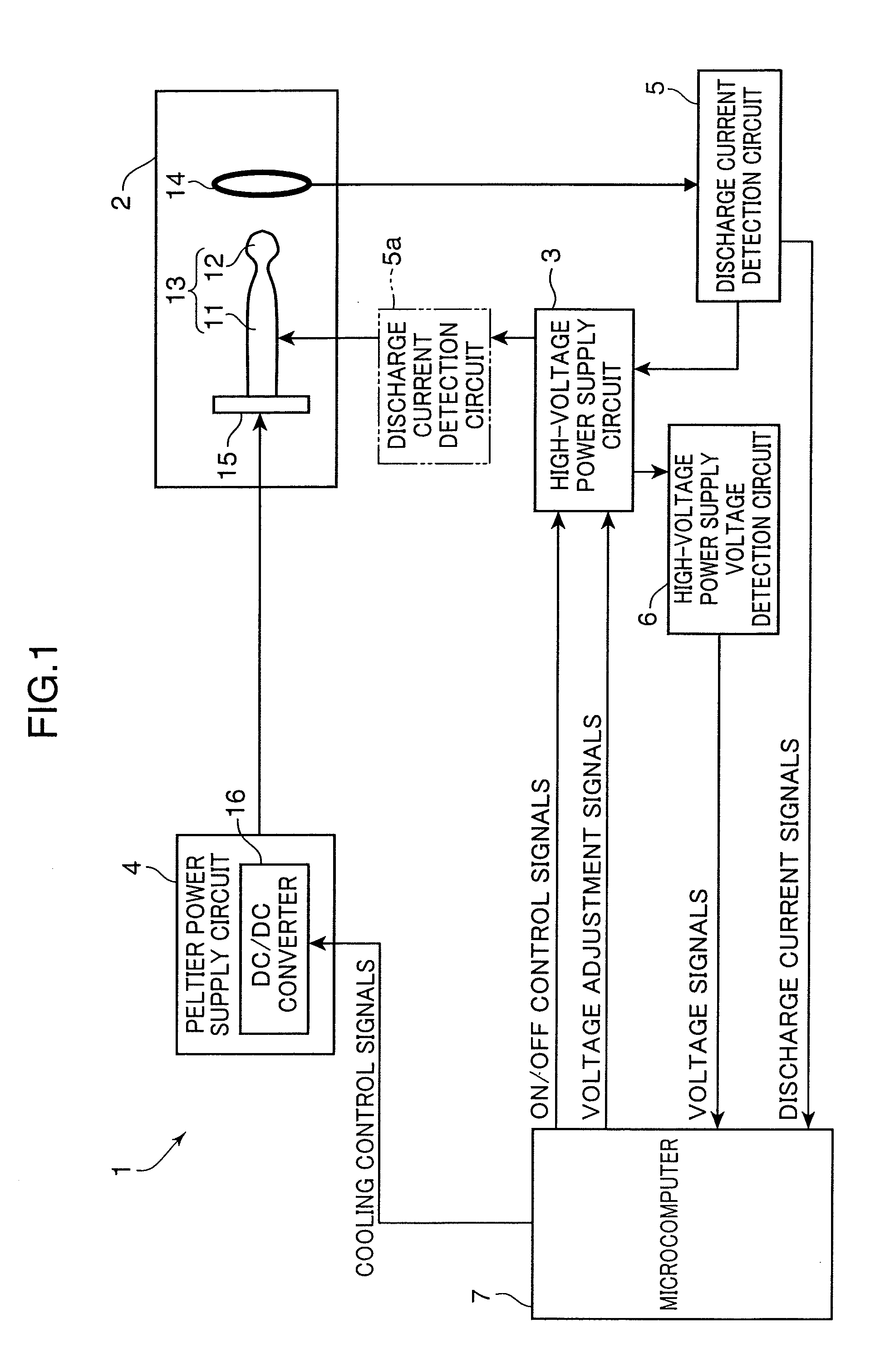

[0027]FIG. 1 is a block diagram showing the electrical configuration of the electrostatic atomizing device 1 in a first embodiment of the invention. This electrostatic atomizing device 1 comprises an atomizing block 2, high-voltage power supply circuit 3, Peltier power supply circuit 4, discharge current detection circuit 5, high-voltage power supply voltage detection circuit 6, and microcomputer (control portion) 7. This electrostatic atomizing device 1 is provided on the downstream side in the direction of flow of air from the filter 90 of an air conditioner 30 (see FIG. 13). For example, if the air conditioner is air cleaning equipment, charged fine water particles (nano-size mist) leaving the electrostatic atomizing device 1 by means of an ion wind generated from an ion generation portion (not shown) is carried on the air current of the air conditioner 30, and is dispersed within the room.

[0028]The atomizing block 2 comprises an atomizing electrode 13 having a spherical body 12 ...

embodiment 2

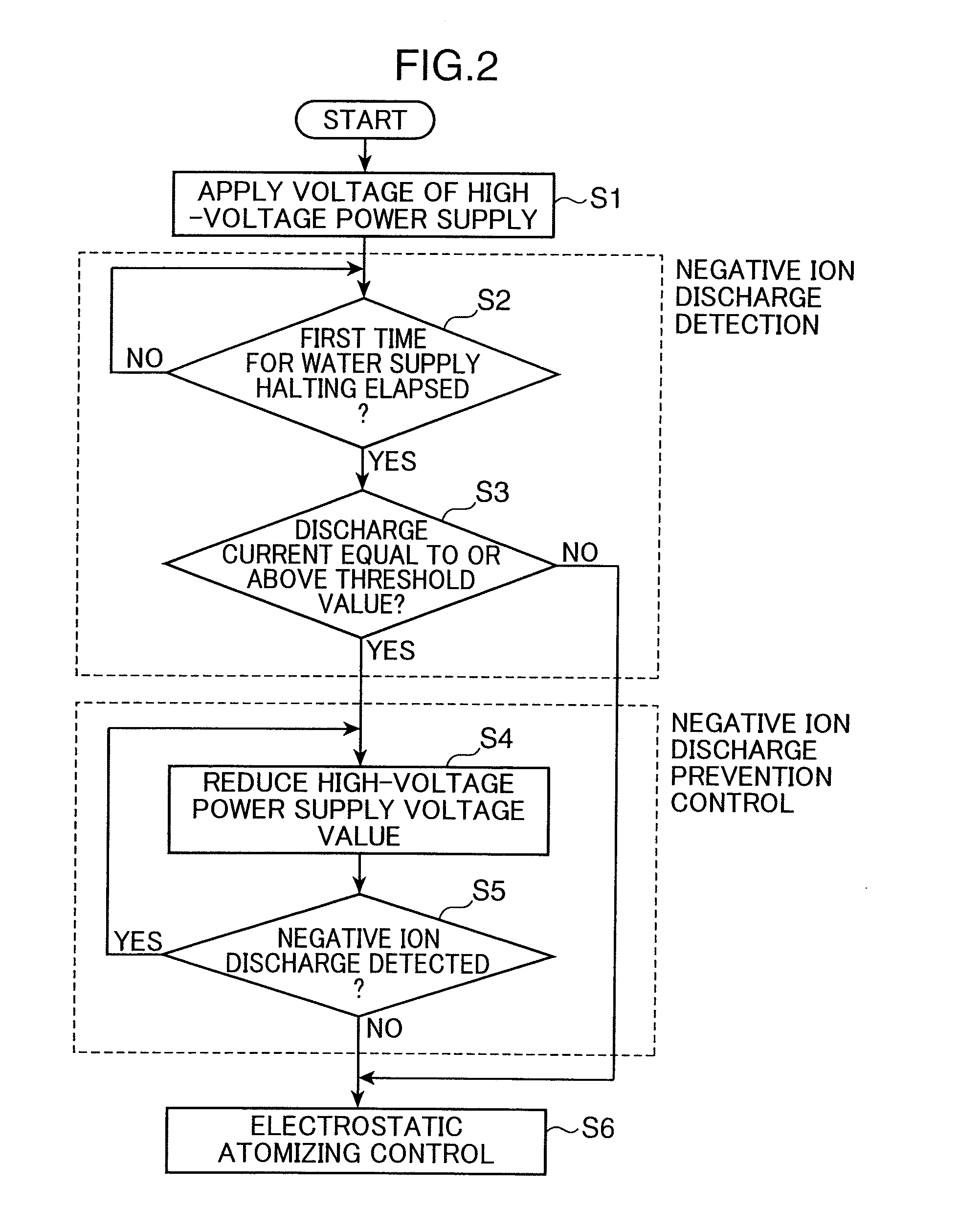

[0053]FIG. 5 is a flowchart used to explain operation of the electrostatic atomizing device 1 in a second embodiment of the invention. The configuration of the electrostatic atomizing device 1 shown in FIG. 1 can be used in the electrostatic atomizing device 1 of this embodiment. In the electrostatic atomizing device 1 of this embodiment, operation of the microcomputer 7 differs between in FIG. 2 and in FIG. 5. In FIG. 5, which is similar to FIG. 2, the same step numbers are assigned to corresponding processing, and explanations thereof are omitted. It should be noted that in this embodiment, after halting supply of water and waiting for a first time in step S2, upon detecting a discharge current value of the discharge current equal to or greater than a threshold value in step S3, no judgment of negative ion discharge is performed immediately, and processing returns to step S3 until a predetermined second time elapses, and after the second time has elapsed, judgment of negative ion ...

embodiment 3

[0056]FIG. 6 is a flowchart used to explain operation of the electrostatic atomizing device 1 in a third embodiment of the invention. The configuration of the electrostatic atomizing device 1 shown in FIG. 1 can be used in the electrostatic atomizing device 1 of this embodiment. In the electrostatic atomizing device 1 of this embodiment, operation of the microcomputer 7 differs from that in FIG. 2 above and in FIG. 6. It should be noted that in this embodiment, the negative ion discharge detection processing indicated in steps S2 and S3 of FIG. 2 is performed in step S23.

[0057]That is, in the state in which the supply of water to the atomizing electrode 13 is halted during the period of the first time (step S2 in FIG. 2), the microcomputer 7 performs processing to judge whether the discharge current value is equal to or exceeds the threshold value (step S3 in FIG. 2). And, in step S3 in FIG. 2, upon detection of negative ion discharge (YES in step S3 of FIG. 2), the microcomputer 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com