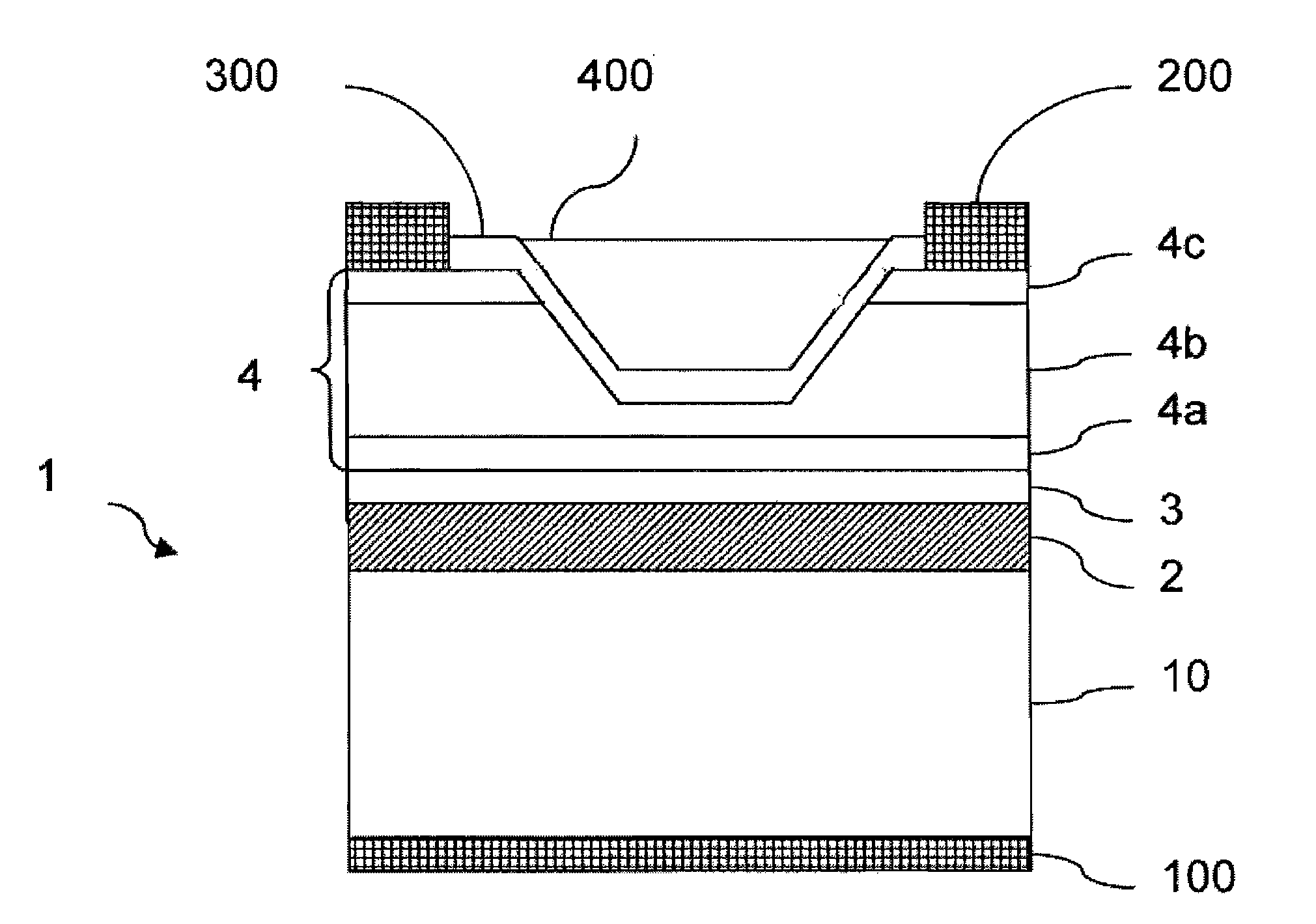

Heterostructure for electronic power components, optoelectronic or photovoltaic components

a technology of optoelectronic or photovoltaic components and electronic power components, applied in the direction of crystal growth process, polycrystalline material growth, transportation and packaging, etc., can solve the problems of reducing the effectiveness of electronic, optical or optoelectronic devices formed on this material, difficult to manufacture with current technologies, and high cost, so as to facilitate the epitaxial growth of an active layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

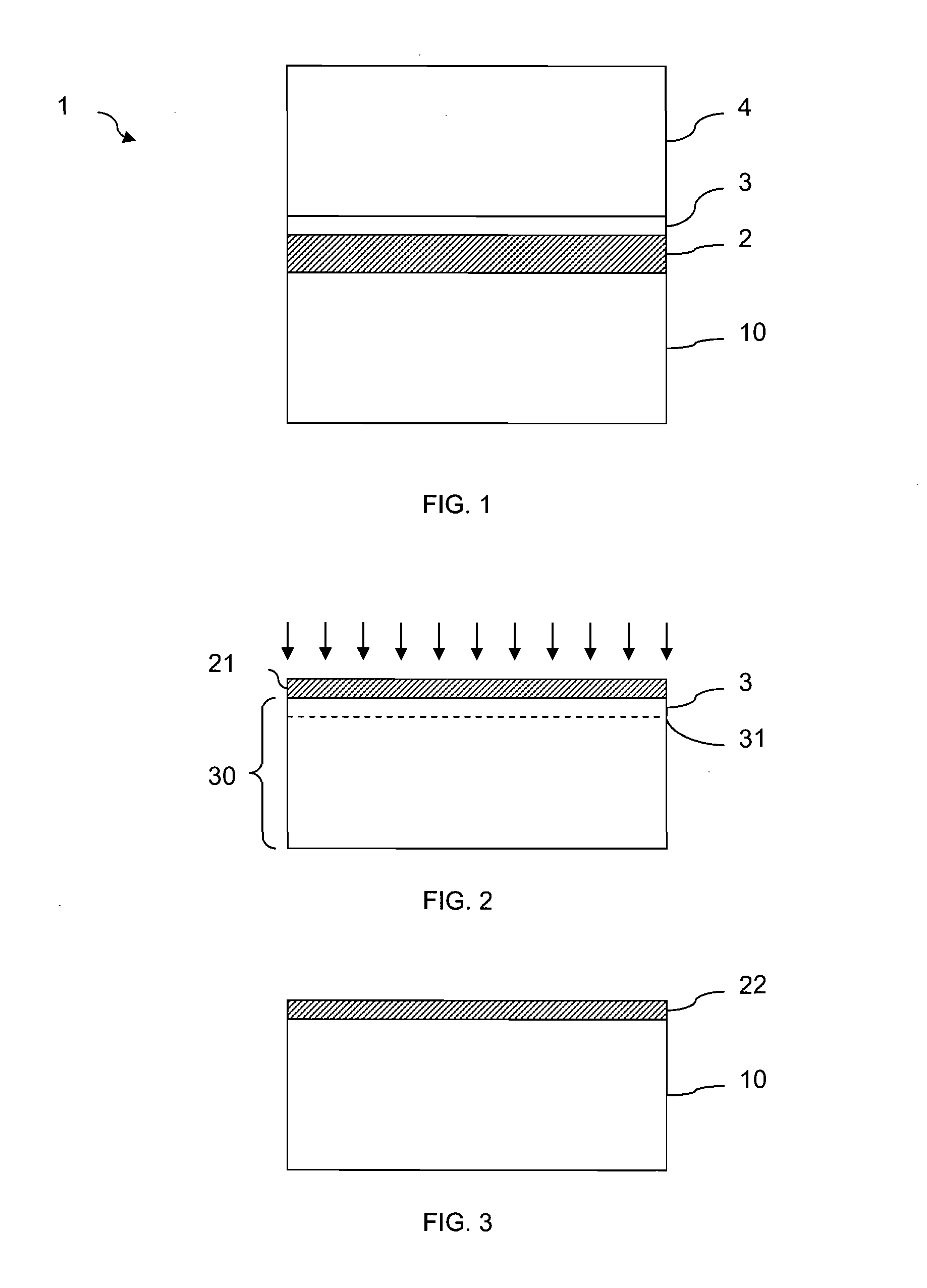

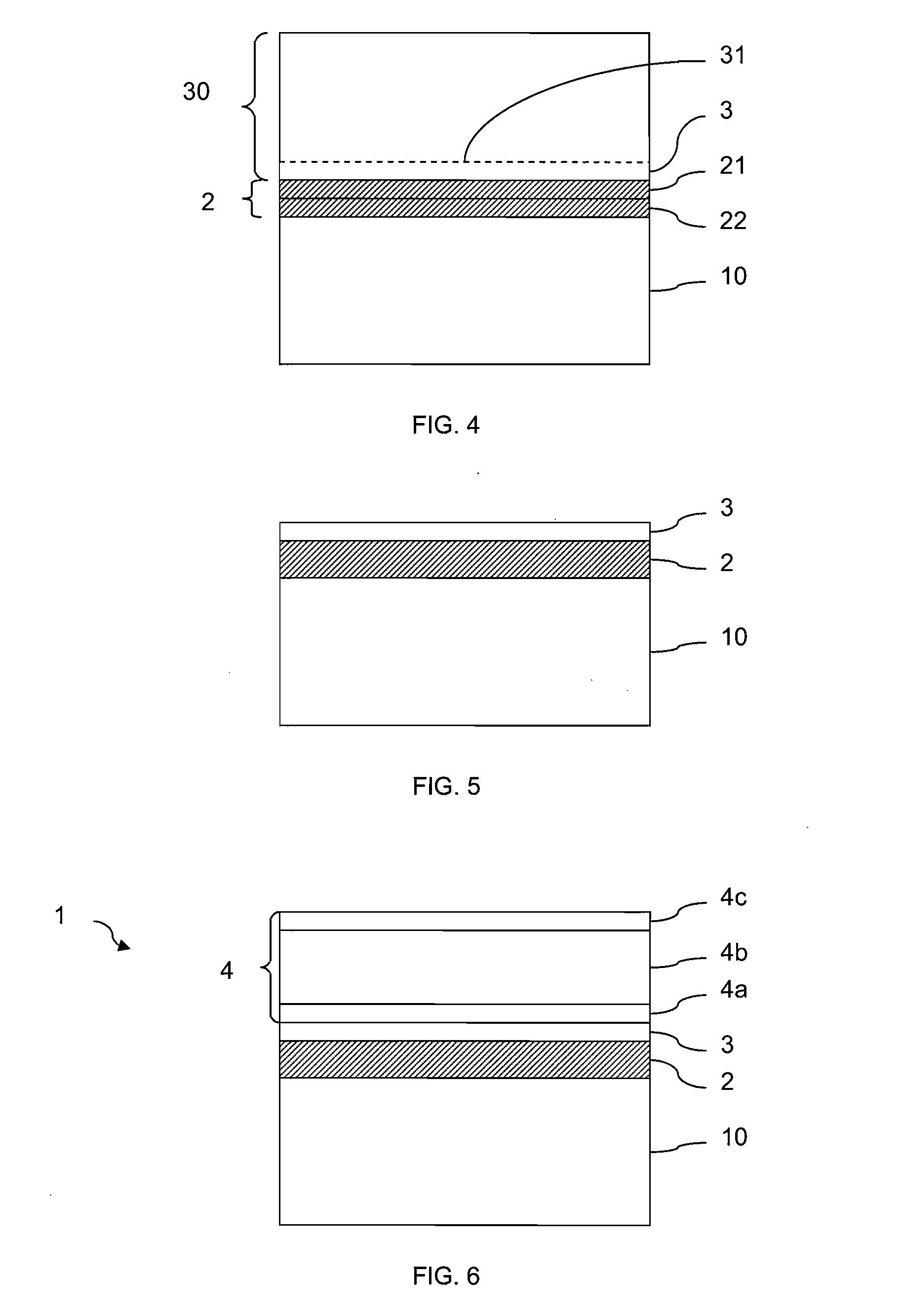

Embodiment Construction

[0045]In the present text, “layer portion” is understood to refer to a part of a layer considered in the sense of the thickness of the layer. Thus, a layer may be constituted of several stacked portions, the sum of the thicknesses of portions being equal to the total thickness of the layer. The different portions of the active layer may be in the same material, but with different doping, or rather may be in different materials of composition AlxInyGa(1-x-y)N, where 0≦x≦1, 0≦y≦1 and x+y≦1. Thus, the active layer of a PIN diode may be designed with alternating InGaN / GaN / InGaN or doped p GaN / weakly doped GaN / doped n GaN layers. The active layer for optoelectronic or photovoltaic components may be constituted of a stack of layers in different materials of composition AlxInyGa(1-x-y)N, where 0≦x≦1, 0≦y≦1 and x+y≦1.

[0046]In addition, “subjacent” designates a layer portion the farthest removed from the surface of the heterostructure and “superjacent” designates a layer portion closest to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com