Method for manufacture of a package for the transport and/or storage of nuclear material, using the phenomenon of welding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

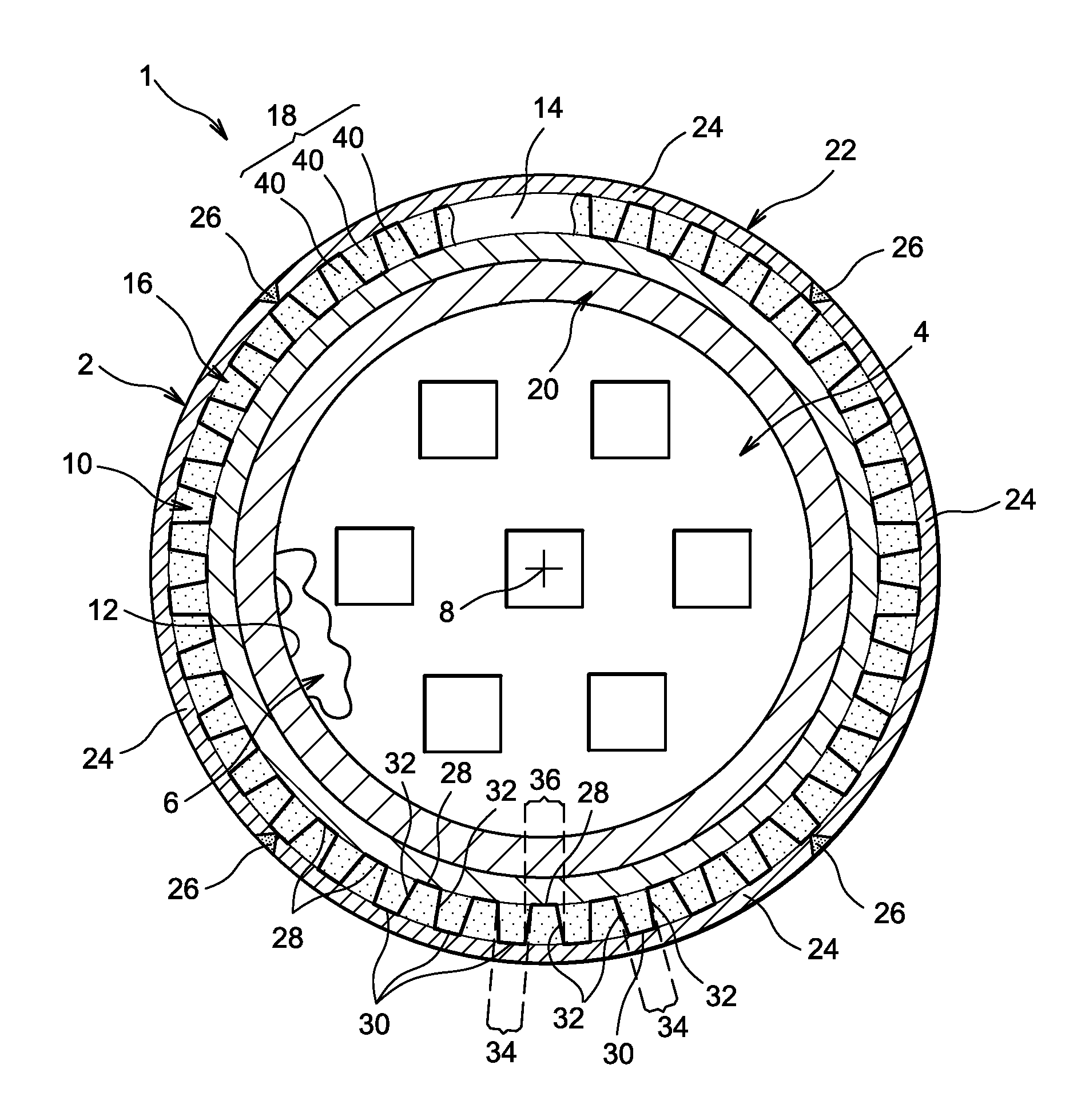

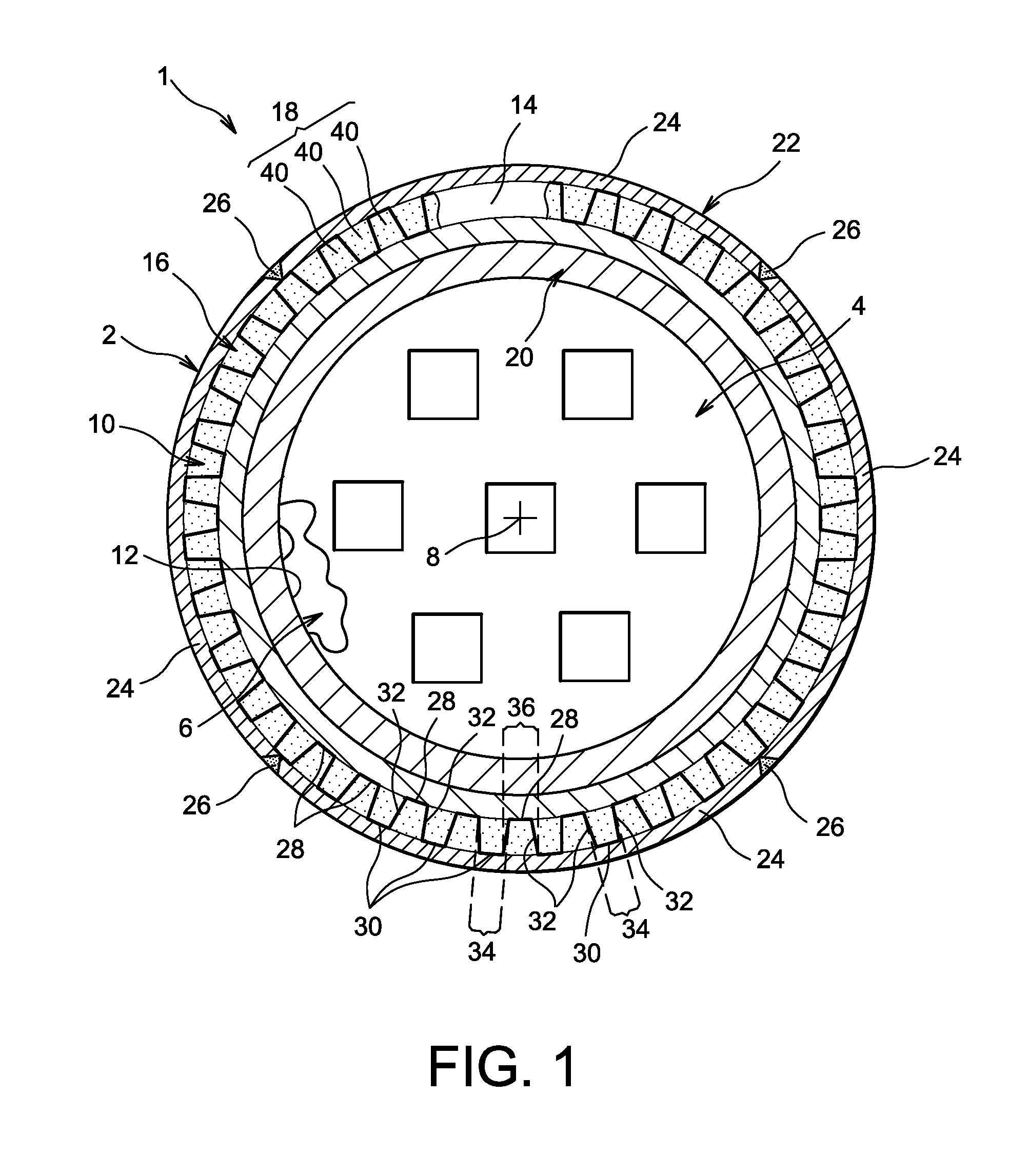

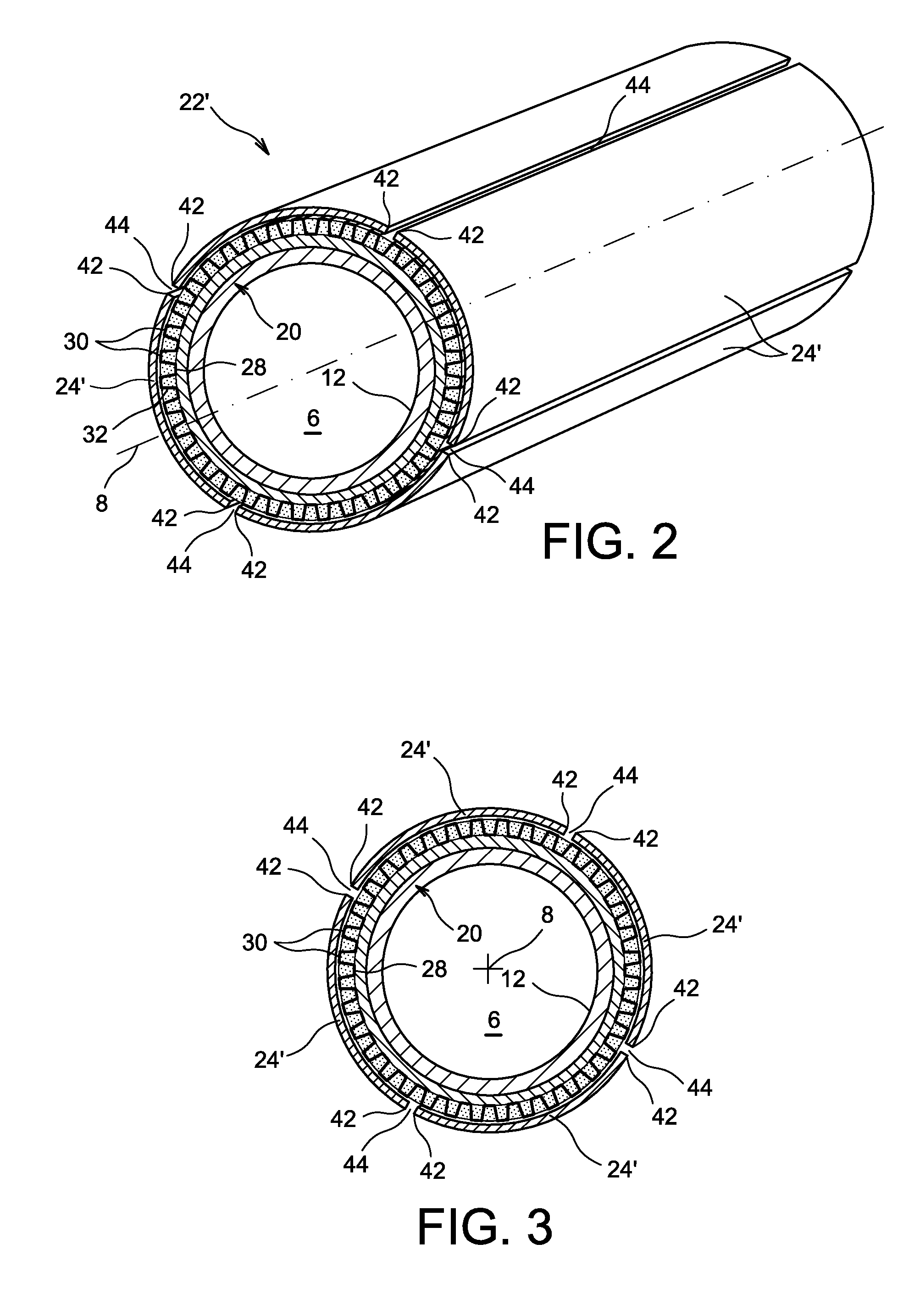

[0048]Firstly, with reference to FIG. 1, a container 1 for the transport and / or storage of assemblies of nuclear fuel can be seen. It is with this regard recalled that the invention is not limited in any way to the transport / storage of this type of nuclear material. As an example, the invention can also be applied to the transport / storage of PuO2 powder.

[0049]Container 1 comprises globally a package 2 forming the subject of the present invention, inside which is a storage device 4, also called a storage basket. Device 4 is designed to be positioned in a receptacle cavity 6 of package 2, as is shown schematically in FIG. 1, where it is also possible to note the lengthways axis 8 of this package, merged with the lengthways axes of the storage device and the receptacle cavity.

[0050]Throughout the disclosure the term “lengthways” must be understood as being parallel to the lengthways axis 8 and to the lengthways direction of the package, and the term “transverse” must be understood as b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com