Collapsible music stand extension device

a technology for extension devices and music stands, which is applied in the direction of lecterns, furniture parts, machine supports, etc., to achieve the effects of reducing device size, cost-effectiveness, and no adverse impact on device utility or portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

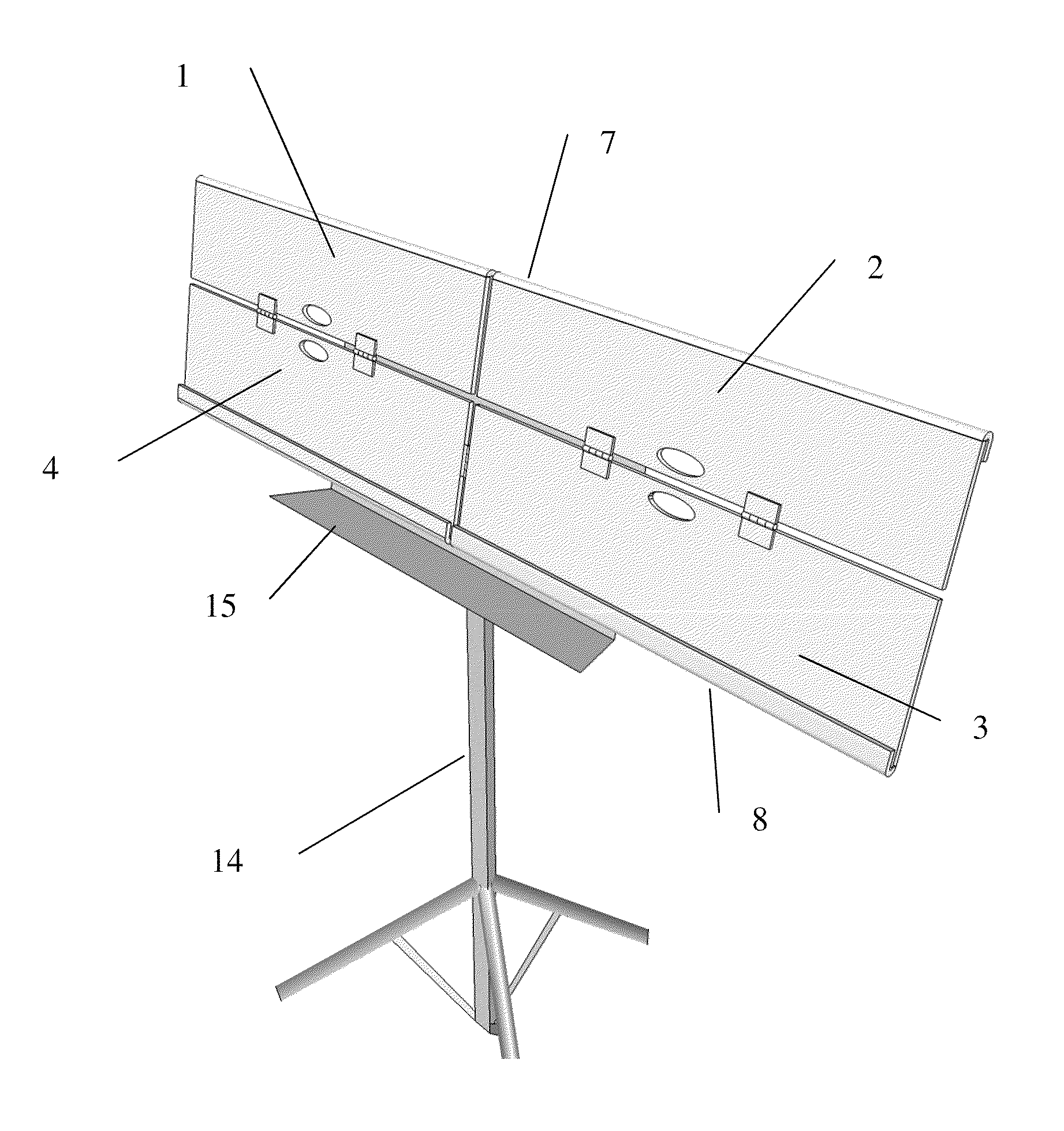

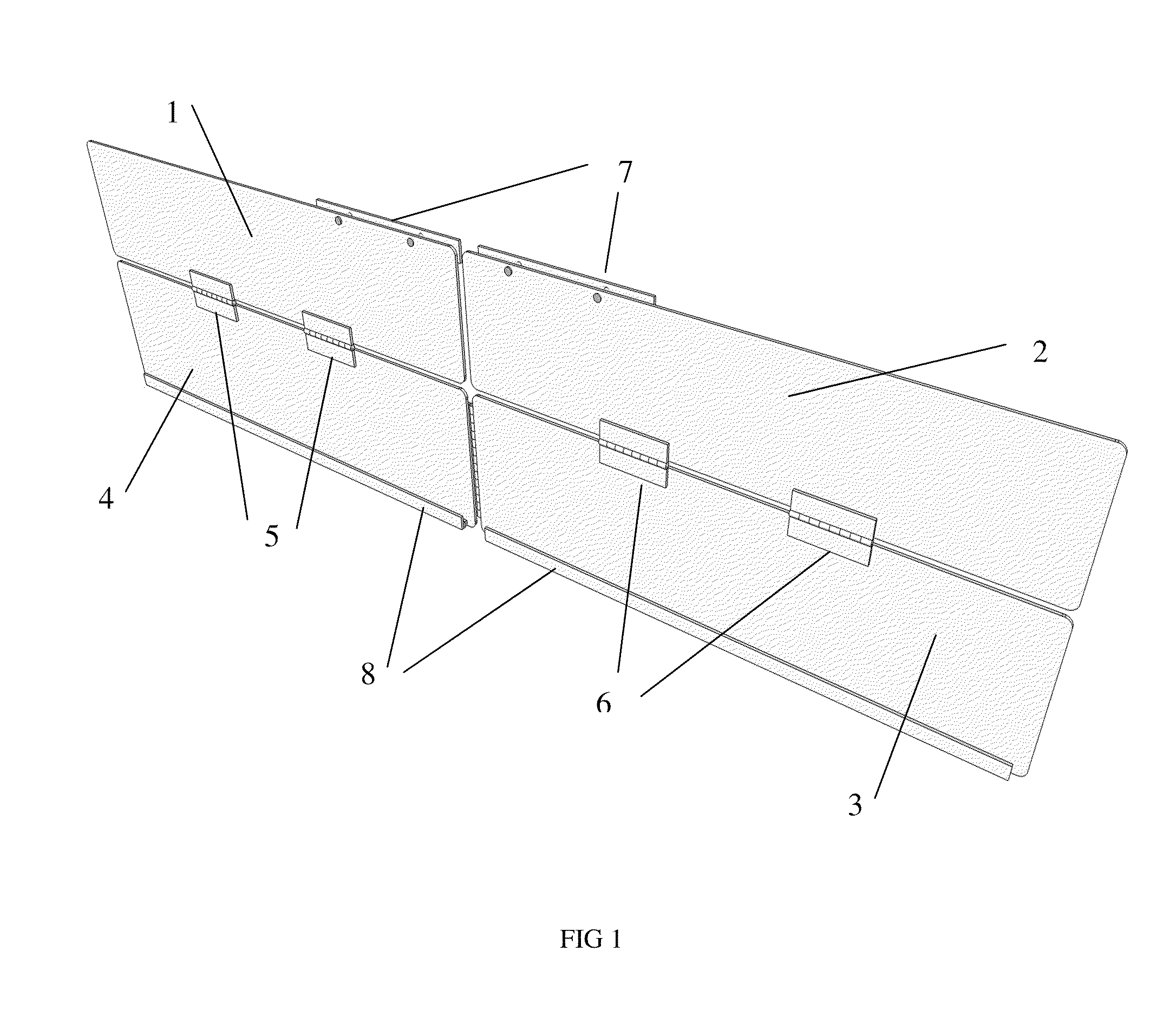

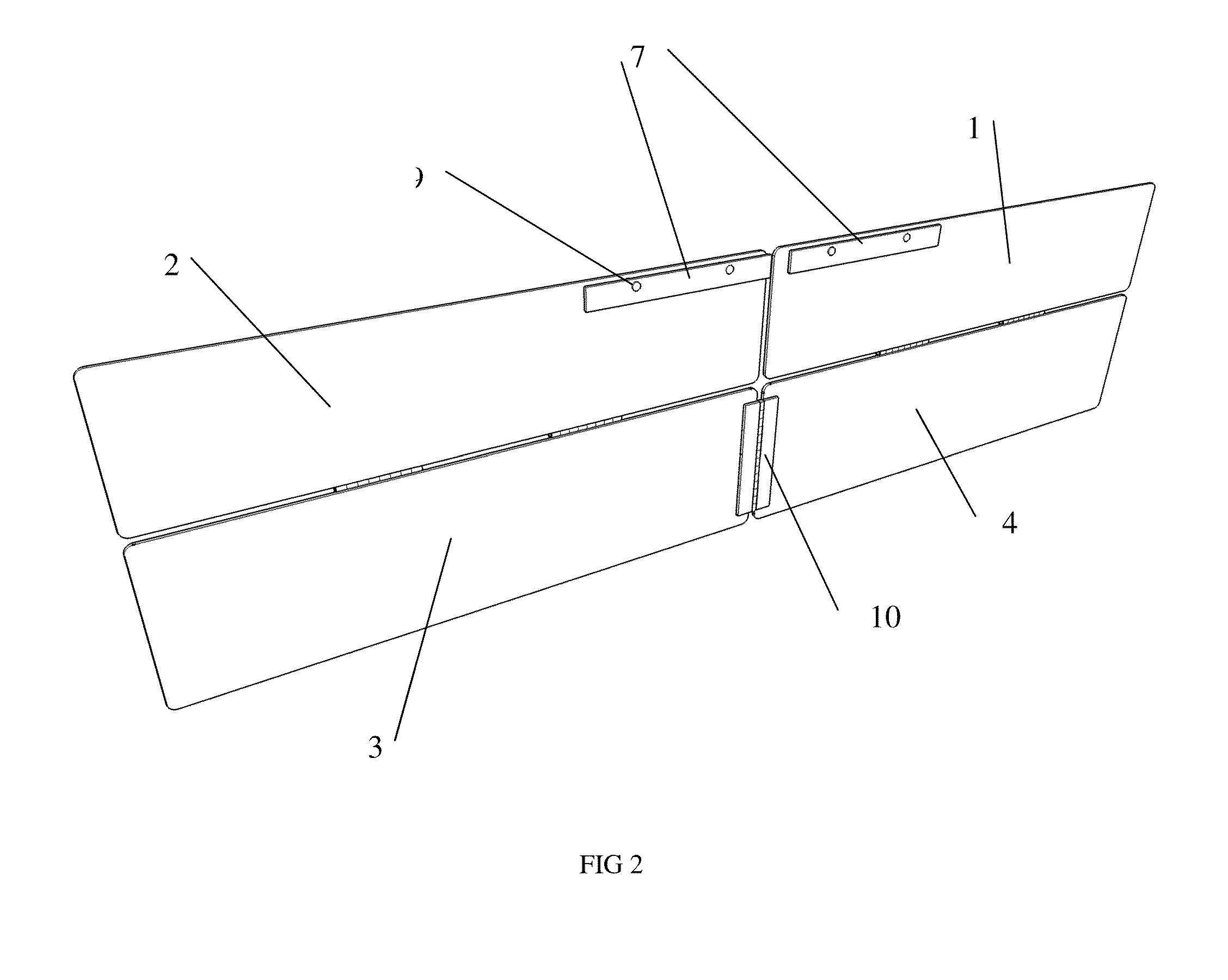

[0043]Referring to FIG. 1, the present invention consists of a set of four thin rectangular sections 1, 2, 3, and 4, each section similar to the others, except that the two upper sections 1 and 2 are nominally one inch smaller than the two lower sections 3 and 4 in the preferred embodiment, as measured in the vertical (smaller) dimension of each rectangle. In the preferred embodiment, each rectangular section 1, 2, 3 and 4 is about 24 inches in width, with the upper sections 1 and 2 about 5.5 inches in height and the lower sections 3 and 4 about 6.5 inches in height. In the preferred embodiment, rectangular sections 1, 2, 3 and 4 have rounded corners as a safety feature. In the preferred embodiment, the fully assembled and expanded device is approximately 48 inches in length and 12.5 inches in height.

[0044]The present invention can be fabricated from either sheet metal or a thermoplastic material such as acrylic, polycarbonate or acrylonitrile butadiene styrene (ABS). The nature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com