Apparatus, Systems, and Methods for Purification of Isocyanate Mixtures

a technology of isocyanate mixture and apparatus, applied in the field of composition fractionation, can solve the problems of side product stream contaminated with light or heavy components, side product stream contaminated with heavy components, and contamination may persis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

Modeling Isocyanate Fractionation

[0082]An example of the present disclosure was modeled with ASPEN P1us™ software. The model included physical properties of the components validated against laboratory measurements, pilot data, and commercial data. Standard ASPEN Plus unit operation blocks were used to model the columns, reboilers, condensers, liquid and vapor splits. The efficiency of contact devices—contact trays and packing—was validated against the performance of commercial plant data.

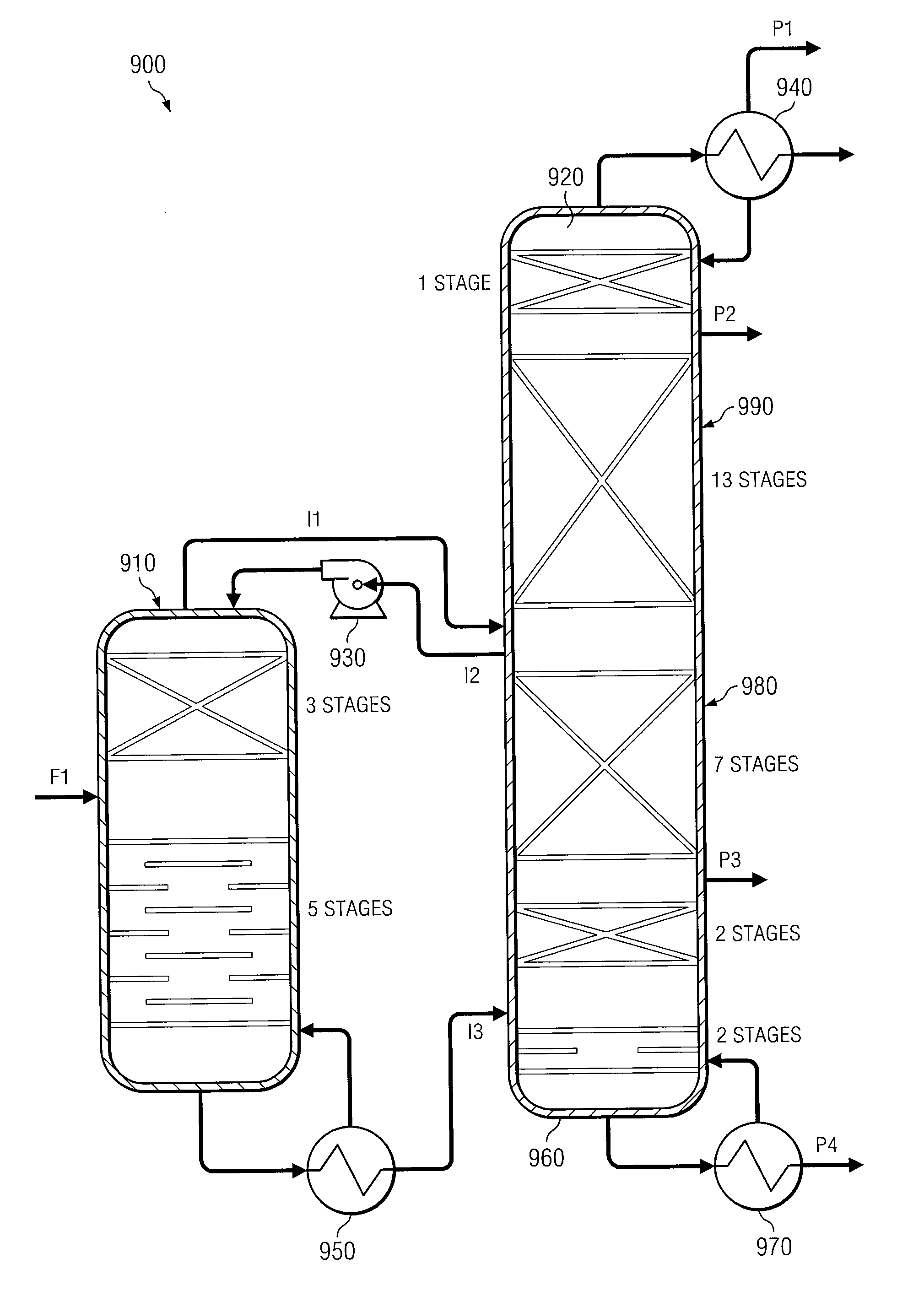

[0083]The feed enters a first (prefractionating) column with 3 packed stages above and 5 stages below as trays. This first column separates ODCB from TDI and heavies before they enter the second (main) column. This separation is driven by a reboiler in the first column. The pressure at the top of the prefractionating section is 40 mmHg. That pressure is higher than the pressure at which Stream I1 enters the main column (i.e., 33 mmHg). This pressure drop causes the vapor to flow without the need for...

example 3

Modeling Isocyanate Fractionation

[0086]An example of the present disclosure was modeled with ASPEN Plus software. The model included physical properties of the components validated against laboratory measurements, pilot data, and commercial data. Standard ASPEN Plus unit operation blocks were used to model the columns, reboilers, condensers, liquid and vapor splits. The efficiency of contact devices—contact trays and packing—was validated against the performance of commercial plant data.

[0087]The feed enters a first (prefractionating) column with 3 packed stages above and 5 stages below as trays. This first column separates ODCB from TDI and heavies before they enter the second (main) column. This separation is driven by a reboiler in the first column. The pressure at the top of the prefractionating section is 40 mmHg. That pressure is higher than the pressure at which Stream I1 enters the main column (i.e., 33 mmHg). This pressure drop causes the vapor to flow without the need for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| total volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com