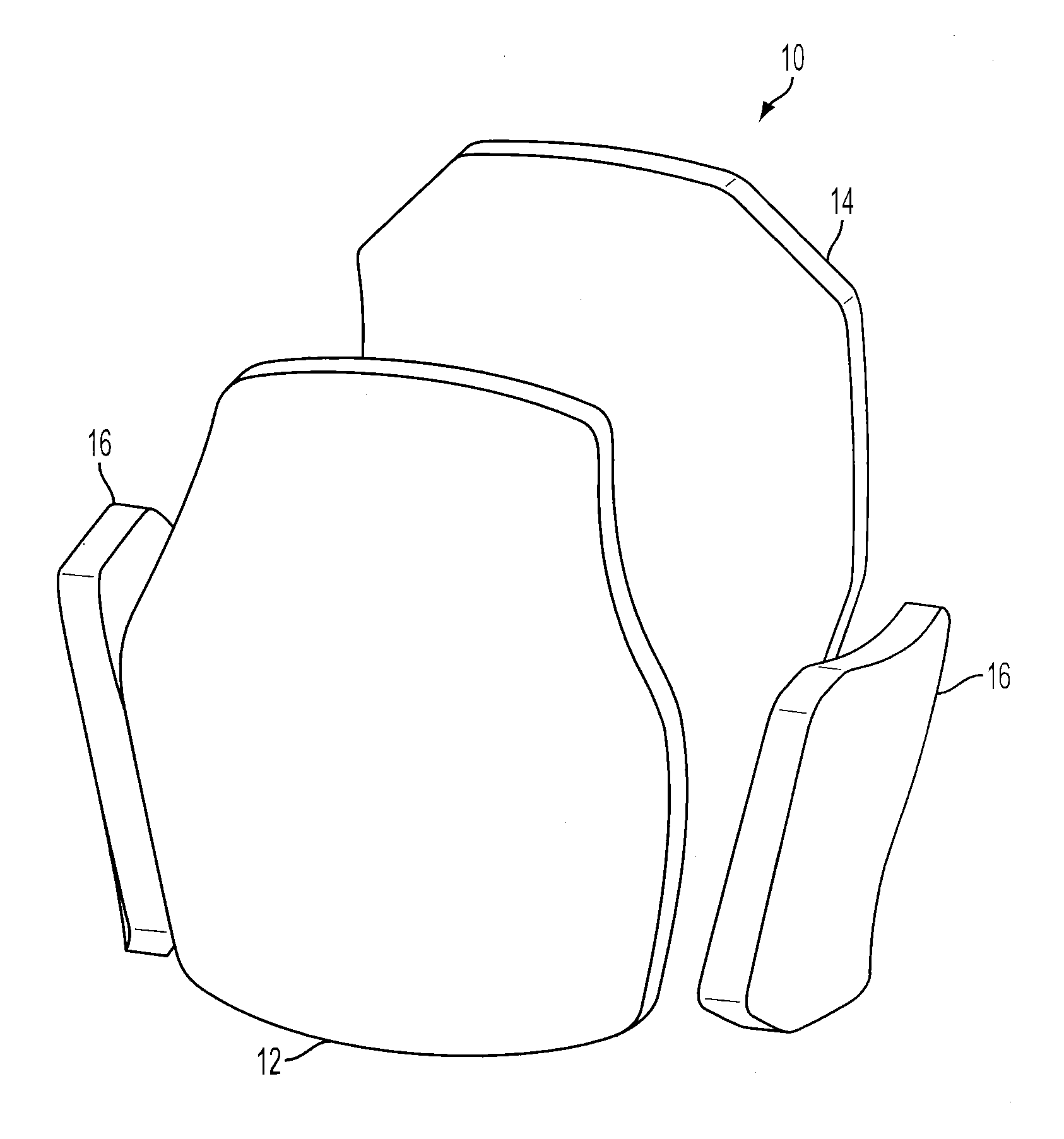

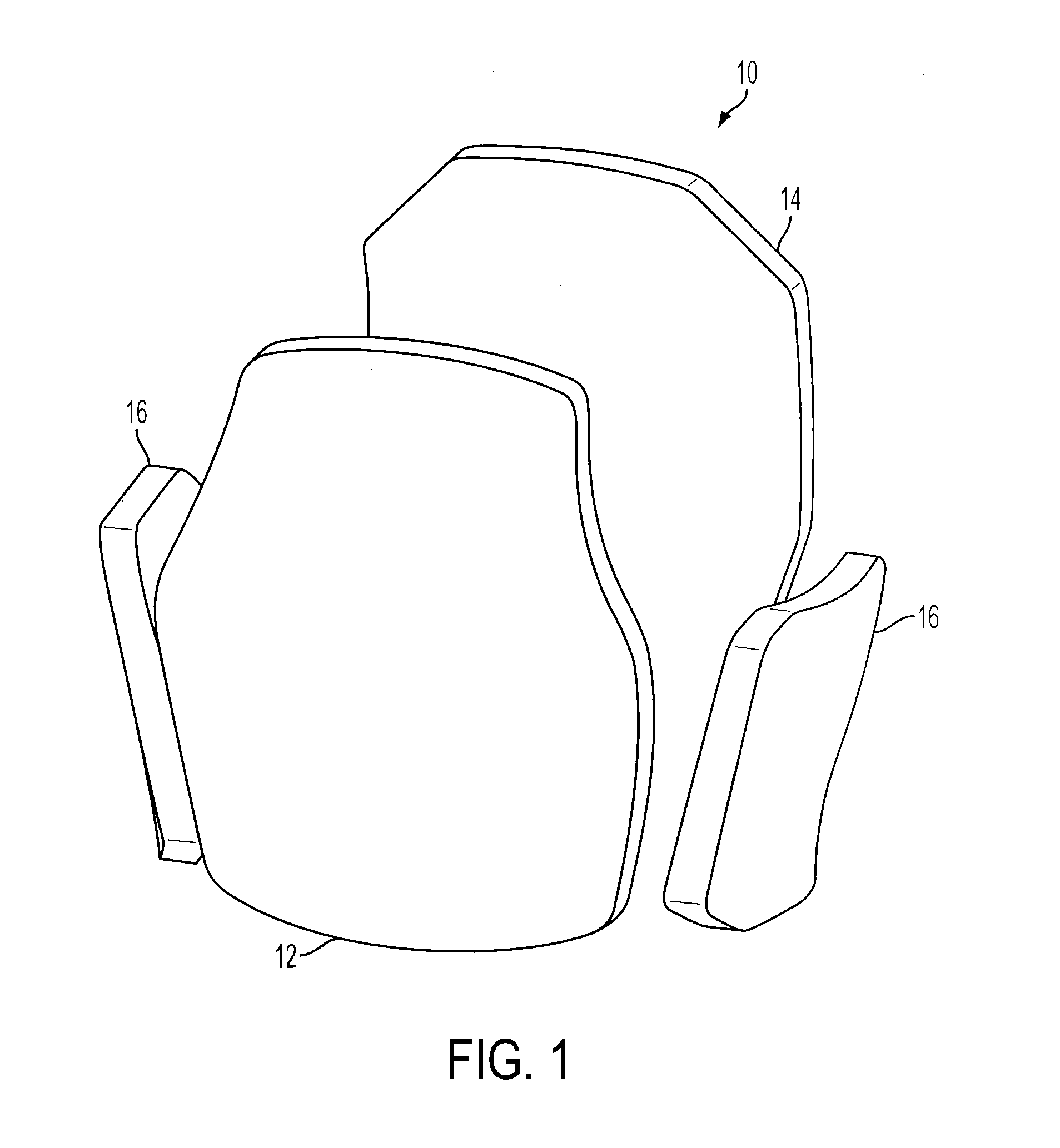

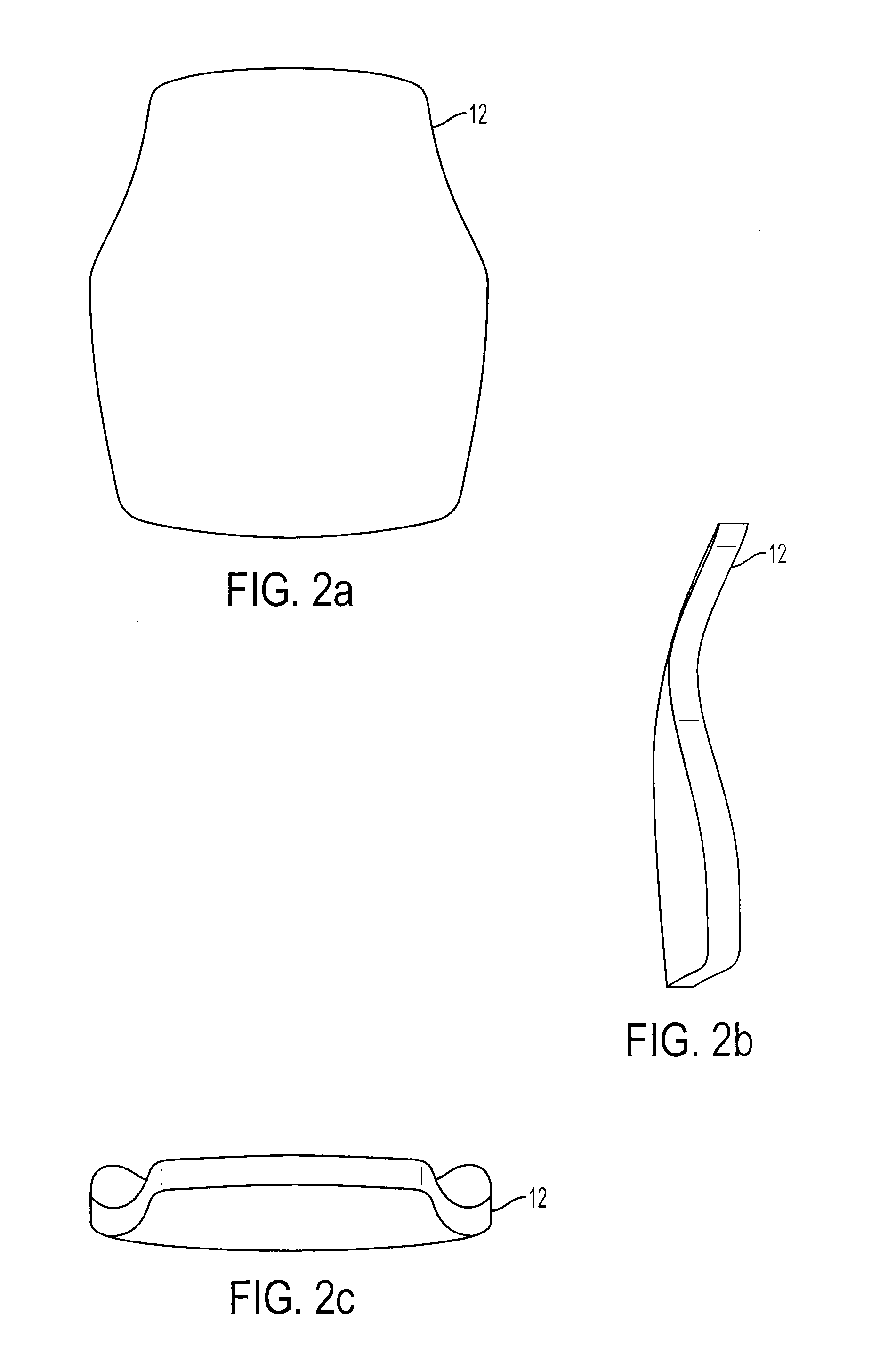

Body Armor Protection System

a protection system and body armor technology, applied in the direction of breathing protection, protective garments, nuclear elements, etc., can solve the problems of system weight and bulk, and achieve the effects of reducing fatigue, optimizing mobility, and maximizing protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

According to the present invention, the preferred ballistic materials for use with the body armor protection system of the present invention is a UHMWPE, .g. Spectra Shield® or Dyneema®, for the reasons listed below. Of course, other materials may be used as would be known to one of skill in the art.

Highest Tenacity

UHMWPE polyethylene fibers have the highest strength-to-weight ratio of any fiber on the market. Not only is UHWMPE 10 times stronger than steel on a per unit weight basis, it is also about 40 percent stronger than aramid fibers, four times stronger than nylons and polyesters, and generally twice as strong as most carbon fibers.

Highest Modulus

UHMWPE leads a field of high-modulus fibers that include aramid, boron, “E” and “S” glass, HT graphite, and liquid crystal polymer. All of these provide high-strength, light-weight contrasts to metals, and all have high stiffness. UHMWPE can have up to 40 times the tensile modulus of nylon and twice that of aramid fibers.

Highest Ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com