Semicoke for protection of blast furnace and use method thereof

A blast furnace protection and semi-coke technology, which is applied in the coking and ironmaking fields, can solve the problems of not mentioning the titanium content and the effect of furnace protection, and achieve the effect of reducing the production cost of ironmaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1.1 Raw material composition and weight ratio of semi-coke

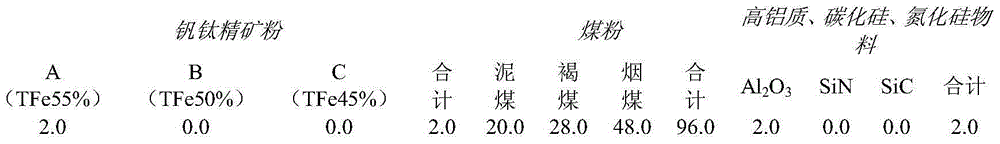

[0019] Raw material composition wt% of table 1 semi-coke

[0020]

[0021] The vanadium-titanium concentrate powder is 2.0%, the coal powder is 96.0%, and the high-aluminum, silicon carbide, and silicon nitride materials are 2.0%. The specific ratio is shown in Table 1. Put the three into Mix in an intensive mixer for 10 minutes, put the evenly mixed materials into the carbonization furnace, and start heating. When the heating temperature reaches 730°C, keep the temperature constant for 5 hours, and finally obtain semi-coke for blast furnace protection.

[0022] 1.2 Semi-focus performance

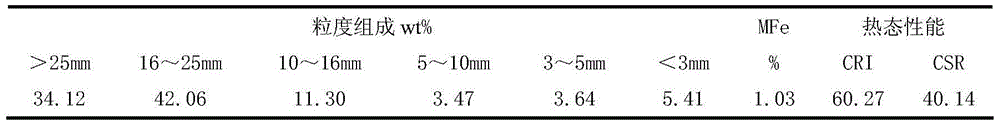

[0023] Table 2 semi-focus performance

[0024]

[0025] 1.3 How to use semi-focus

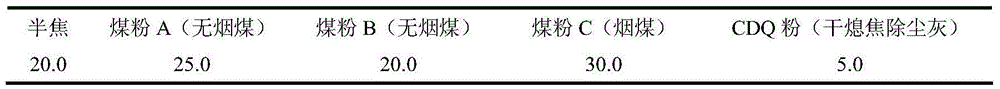

[0026] Table 3 semi-coke (with other pulverized coal ratio) scheme wt%

[0027]

[0028] Semi-coke is stored separately in the raw coal bunker, and put into the main belt for conveying pulverized coal through the coal feeder, an...

Embodiment 2

[0033] 2.1 Raw material composition and weight ratio of semi-coke

[0034] Raw material composition wt% of table 5 semi-coke

[0035]

[0036] The vanadium-titanium concentrate powder is 10.0%, the coal powder is 84.0%, and the high-aluminum, silicon carbide, and silicon nitride materials are 6.0%. The specific ratio is shown in Table 5. Put the three into Mix in an intensive mixer for 20 minutes, put the evenly mixed materials into the carbonization furnace, and start heating. When the heating temperature reaches 760°C, keep the temperature constant for 4 hours, and finally obtain semi-coke for blast furnace protection.

[0037] 2.2 Semi-focus performance

[0038] Table 6 semi-focus performance

[0039]

[0040] 2.3 How to use semi-focus

[0041] Table 7 semi-coke (with other pulverized coal ratio) scheme wt%

[0042]

[0043] The semi-coke is stored separately in the raw coal bunker, put into the main belt for conveying coal powder through the coal feeder, and o...

Embodiment 3

[0048] 3.1 Raw material composition and weight ratio of semi-coke

[0049] Raw material composition wt% of table 9 semi-coke

[0050]

[0051]

[0052] The vanadium-titanium concentrate powder is 15.0%, the coal powder is 80.0%, and the high-aluminum, silicon carbide, and silicon nitride materials are 5.0%. The specific ratio is shown in Table 9. Put the three into Mix in an intensive mixer for 30 minutes, put the evenly mixed materials into the carbonization furnace, and start heating. When the heating temperature reaches 790°C, keep the temperature constant for 3 hours, and finally obtain semi-coke for blast furnace protection.

[0053] 3.2 Semi-focus performance

[0054] Table 10 semi-focus performance

[0055]

[0056] 3.3 How to use semi-focus

[0057] Table 11 semi-coke (with other pulverized coal ratio) scheme wt%

[0058]

[0059] The semi-coke is stored separately in the raw coal bunker, and put into the main belt for conveying pulverized coal through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com