Fungicide, photo catalytic composite material, adsorbent, and depurative

a technology of photocatalytic composite materials and adsorbents, which is applied in the direction of physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, other chemical processes, etc., can solve the problem of difficult to say that the ag containing zeolite described above has sufficient properties, and achieves high functionality, high property, and increased adhesion of functional materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0079]Example 1 relates to the fungicide of the embodiment of the present invention. The fungicide of Example 1 includes:

[0080](A) a porous carbon material specifically, having a plant-derived material containing therein silicon as a raw material, more specifically, a porous carbon material having a plant-derived material containing therein silicon having a content rate of 5 wt % or more as a raw material, the content rate of silicon being equal to or smaller than 1 wt %; and

[0081](B) a silver member (silver material) adhered to the porous carbon material,

[0082]in this case, a value of a specific surface area based on the nitrogen BET method is equal to or larger than 10 m2 / g, and a volume of a fine pore based on both the BJH method and the MP method is equal to or larger than 0.1 cm3 / g.

[0083]Or, the fungicide of Example 1 includes:

[0084](A) a porous carbon material; and

[0085](B) a silver member (silver material) adhered to the porous carbon material, and

[0086]the value of the speci...

example 1 -

[Example 1-A]

[0102]Specific surface area: 1,169

[0103]Fine pore volume: 1.04

[0104]BJT(T): 0.64

[0105]MP(T): 0.50

example 1-b

[Example 1-B]

[0106]Specific surface area: 1,217

[0107]Fine pore volume: 1.08

[0108]BJT(T): 0.66

[0109]MP(T): 0.52

[Comparative Example 1 (porous carbon material-B)]

[0110]Specific surface area: 1,300

[0111]Fine pore volume: 1.16

[0112]BJT(T): 0.76

[0113]MP(T): 0.48

[Porous Carbon Material-A]

[0114]Specific surface area: 566

[0115]Fine pore volume: 0.60

[0116]BJT(T): 0.47

[0117]MP(T): 0.17

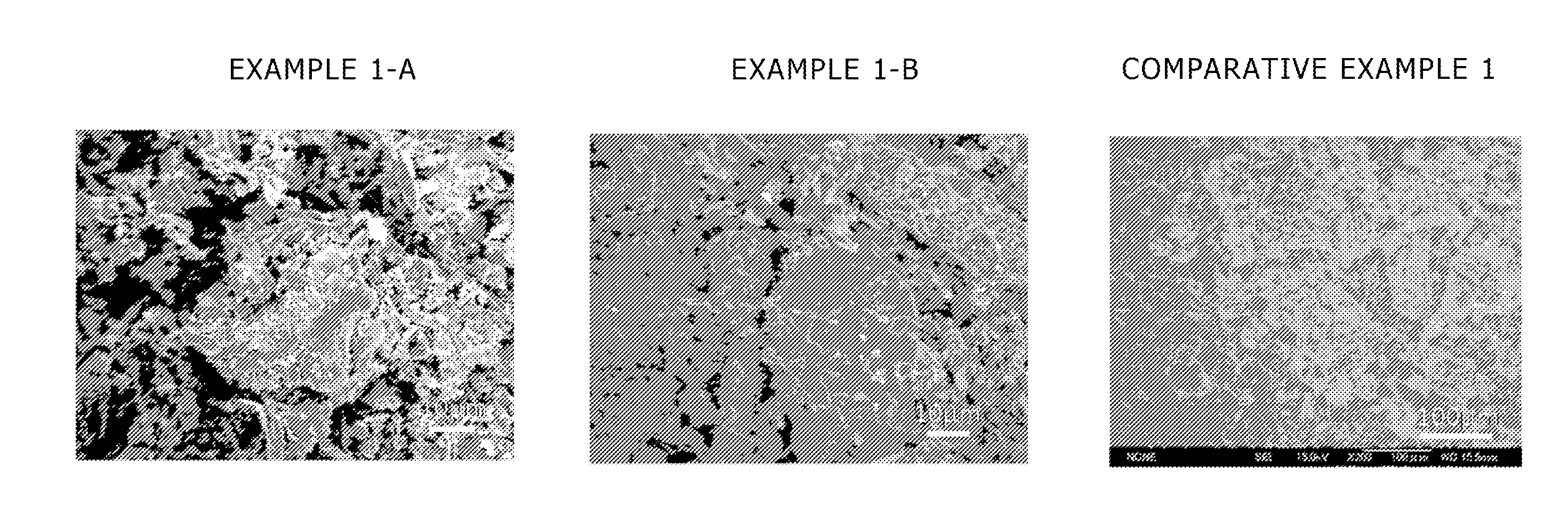

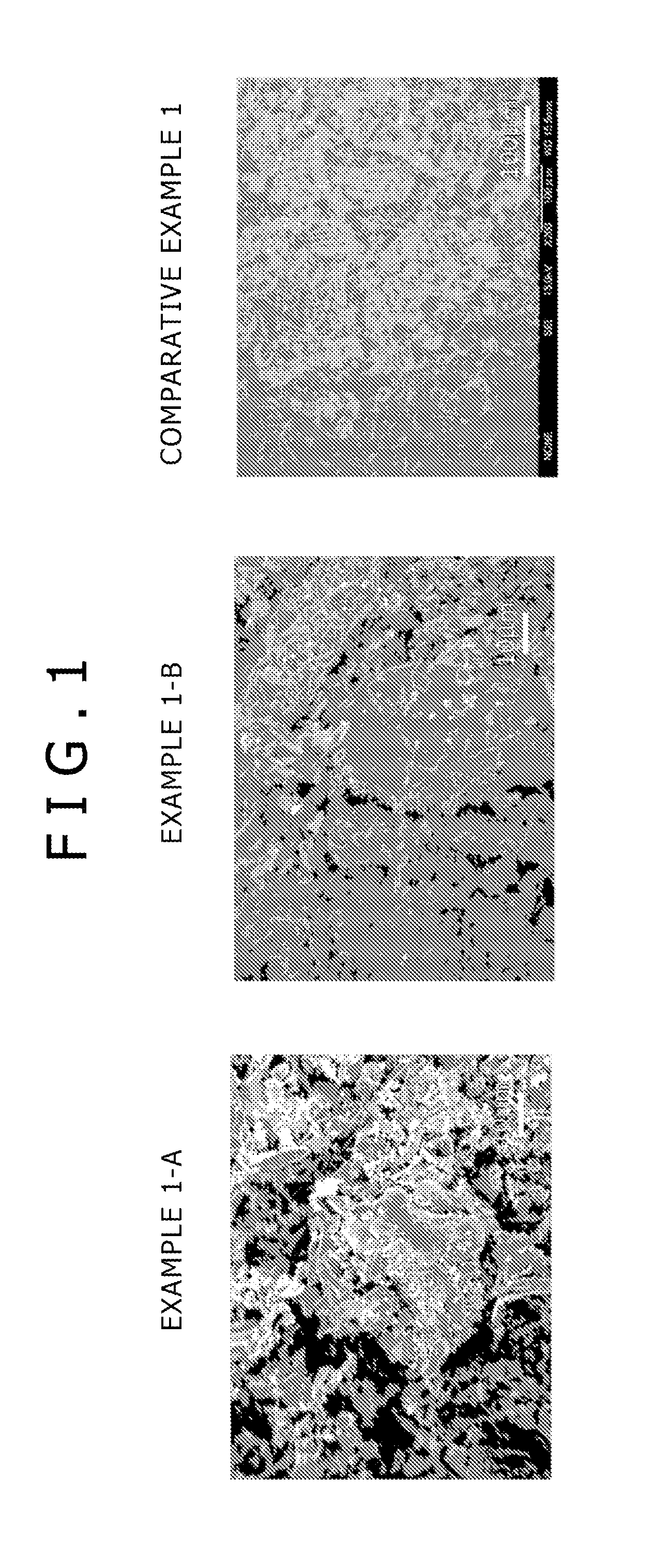

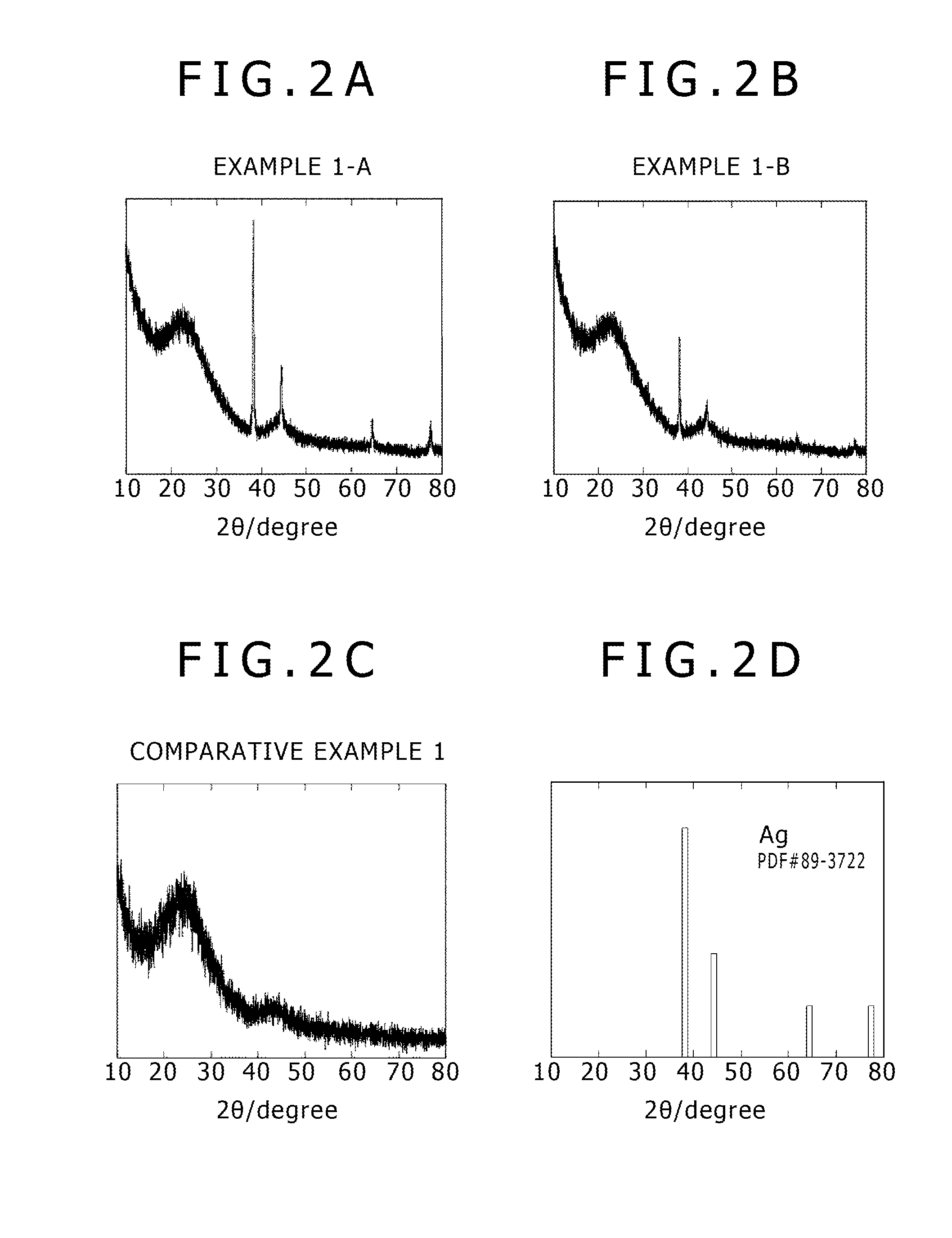

[0118]The value of the specific surface area and the entire fine pore volume, the fine pore volume are smaller in each of the fungicides of Example 1-A and Example 1-B for which the compounding treatment was carried out than in the specimen of Comparative Example 1 for which no compounding treatment was carried out. It is thought that this measurement result results from that by carrying out the compounding treatment, the fine pores of the porous carbon material were filled up by adhesion (precipitation) of the silver particles, or the weight was increased by adhesion (precipitation) of the silver particles.

[011...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com