Passivation methods and apparatus for achieving ultra-low surface recombination velocities for high-efficiency solar cells

a solar cell and ultra-low surface technology, applied in the field of photovoltaics and solar cells, can solve the problems of affecting the production of devices, affecting the efficiency of passivation/arc layer, and affecting the production efficiency of devices, so as to achieve superior surface passivation methods, eliminate or reduce disadvantages and problems, the effect of enhancing optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The following description is not to be taken in a limiting sense, but is made for the purpose of describing the general principles of the present disclosure. The scope of the present disclosure should be determined with reference to the claims. Exemplary embodiments of the present disclosure are described and illustrated in the drawings, like numbers being used to refer to like and corresponding parts of the various drawings.

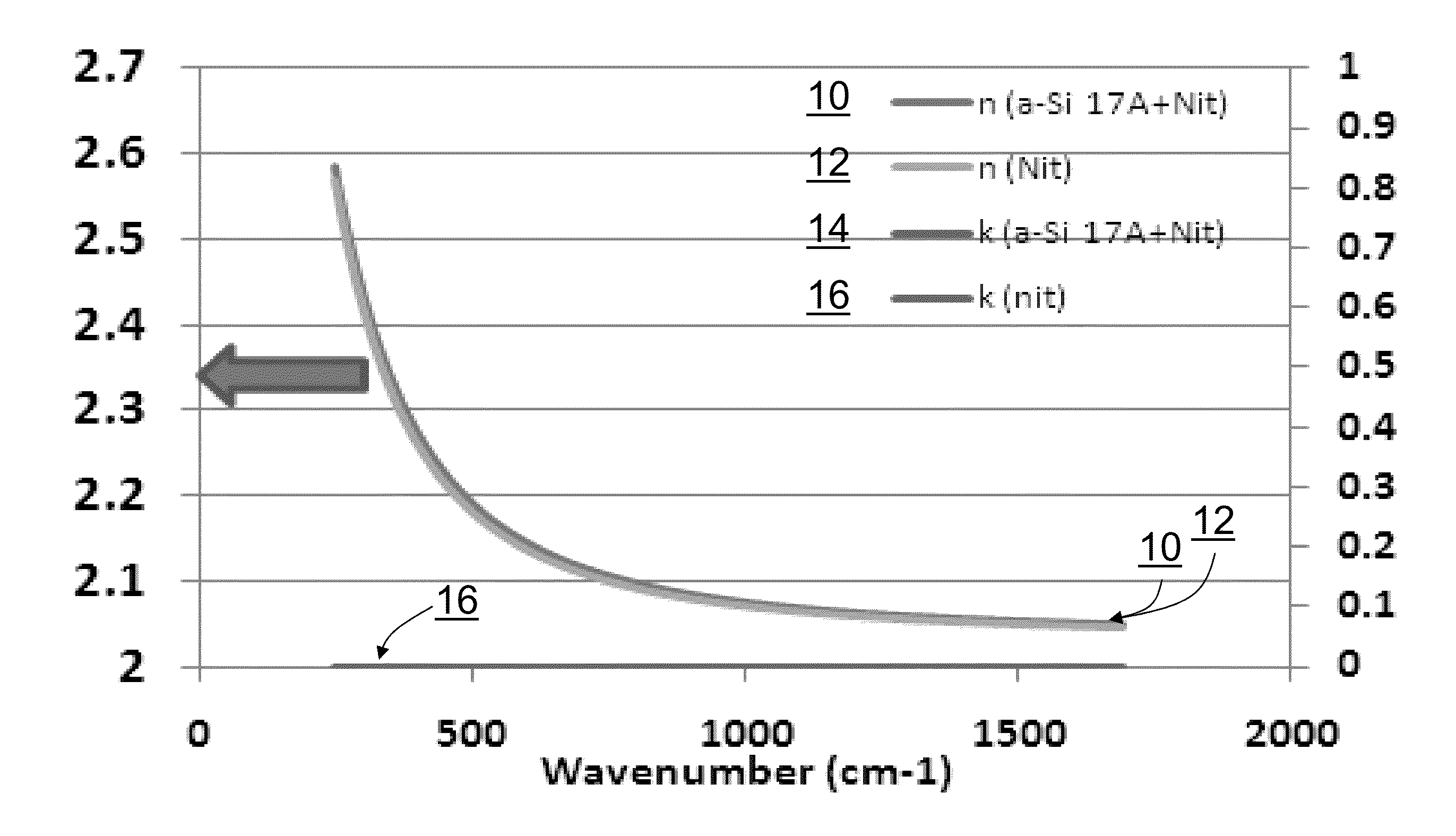

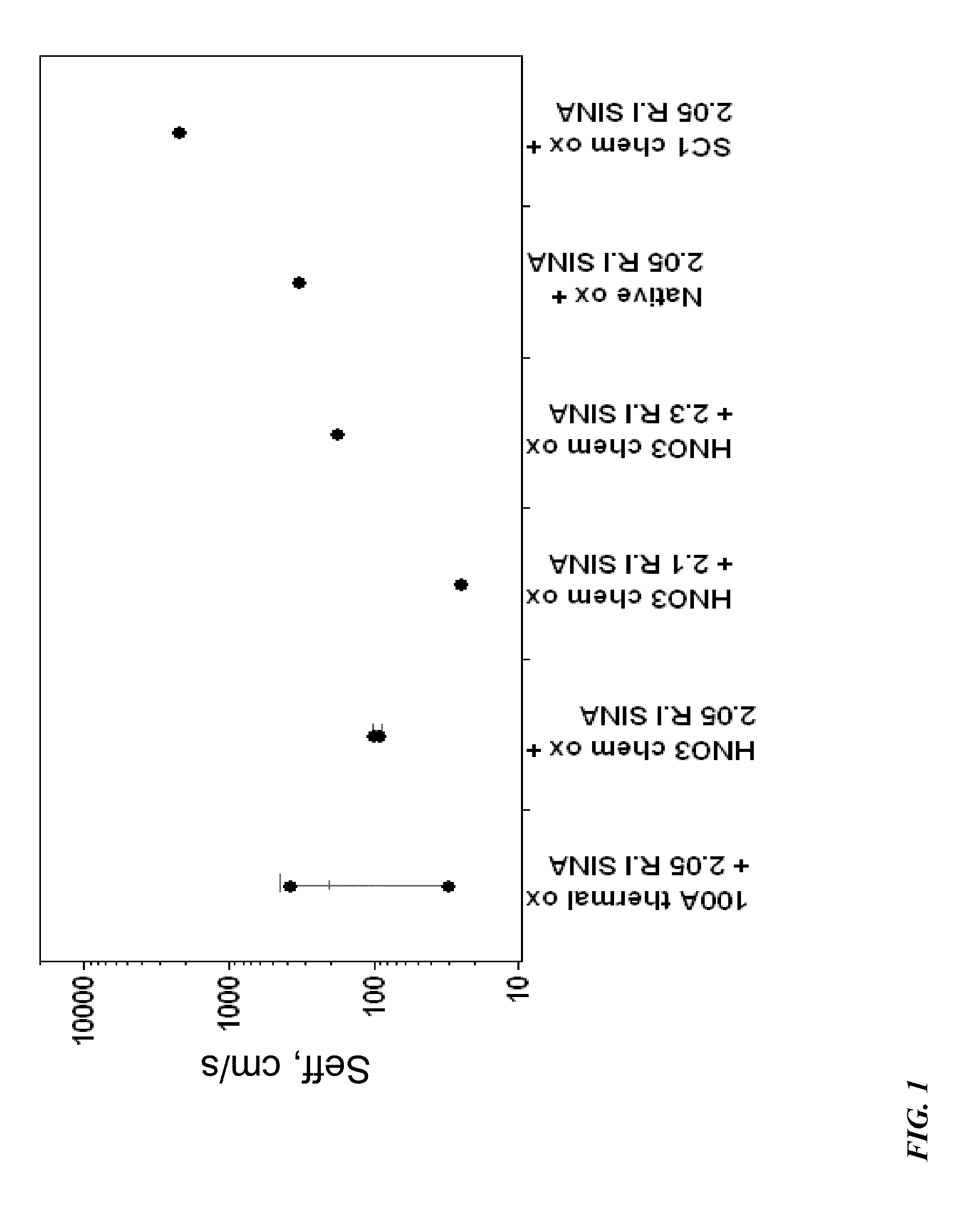

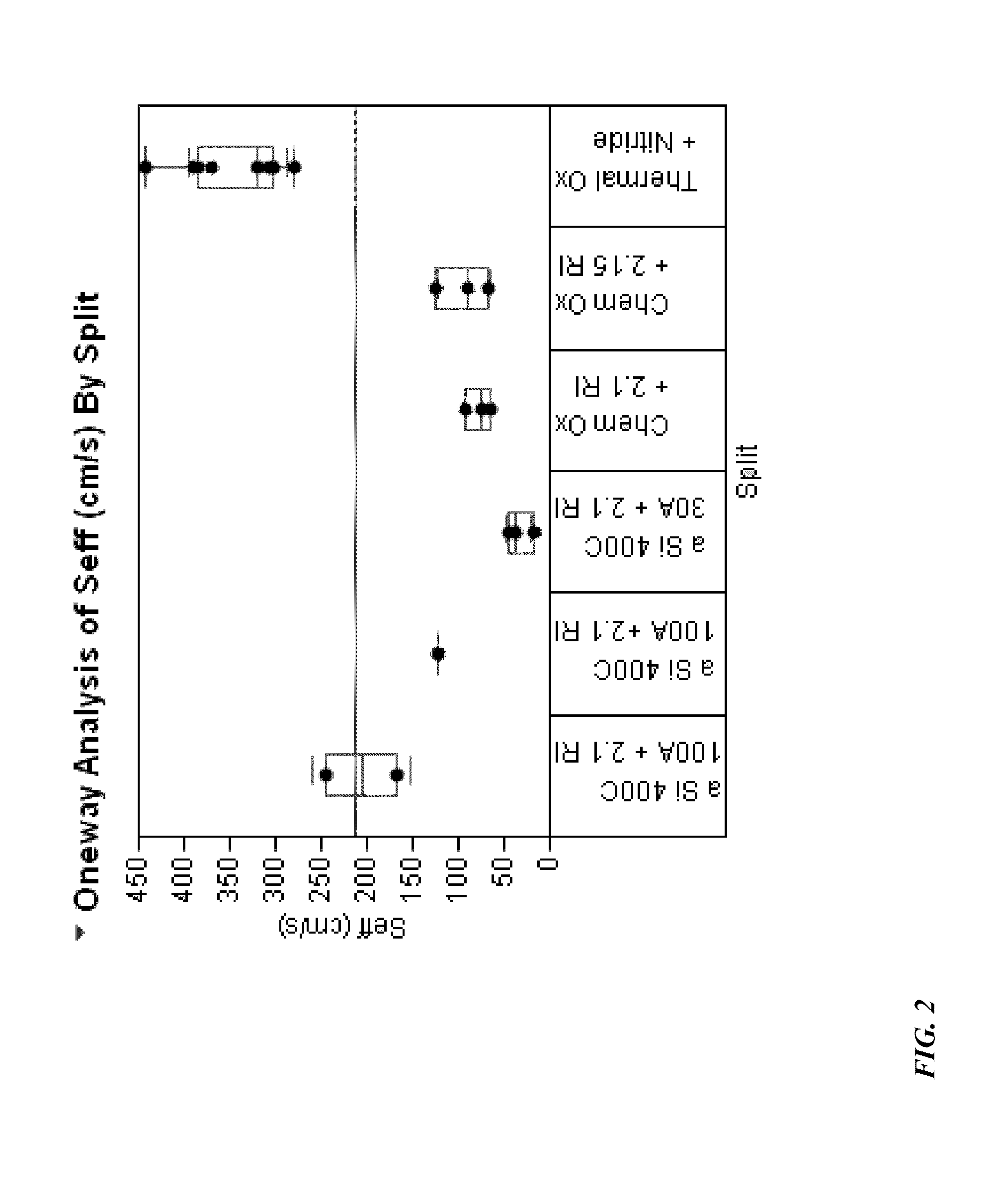

[0018]High-quality surface passivation is needed to obtain low surface recombination velocities and high effective minority carrier lifetimes on crystalline silicon substrates for various applications, including solar photovoltaic cells. Historically superior surface passivation techniques have included using a high temperature thermal oxidation process. However, these high temperature processes may be undesirable for the manufacture of thin film solar cells in part due to the mechanically weak nature of thin film silicon substrates. Thus, the present disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com