Process and apparatus for the preparation of combustible fluid

a technology of combustible fluid and process, which is applied in the field of process and apparatus for the preparation of combustible fluid, can solve the problems of establishing a compelling need to commercialize such devices, and the size and configuration of such molecules can affect burn rate and exhaust products,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

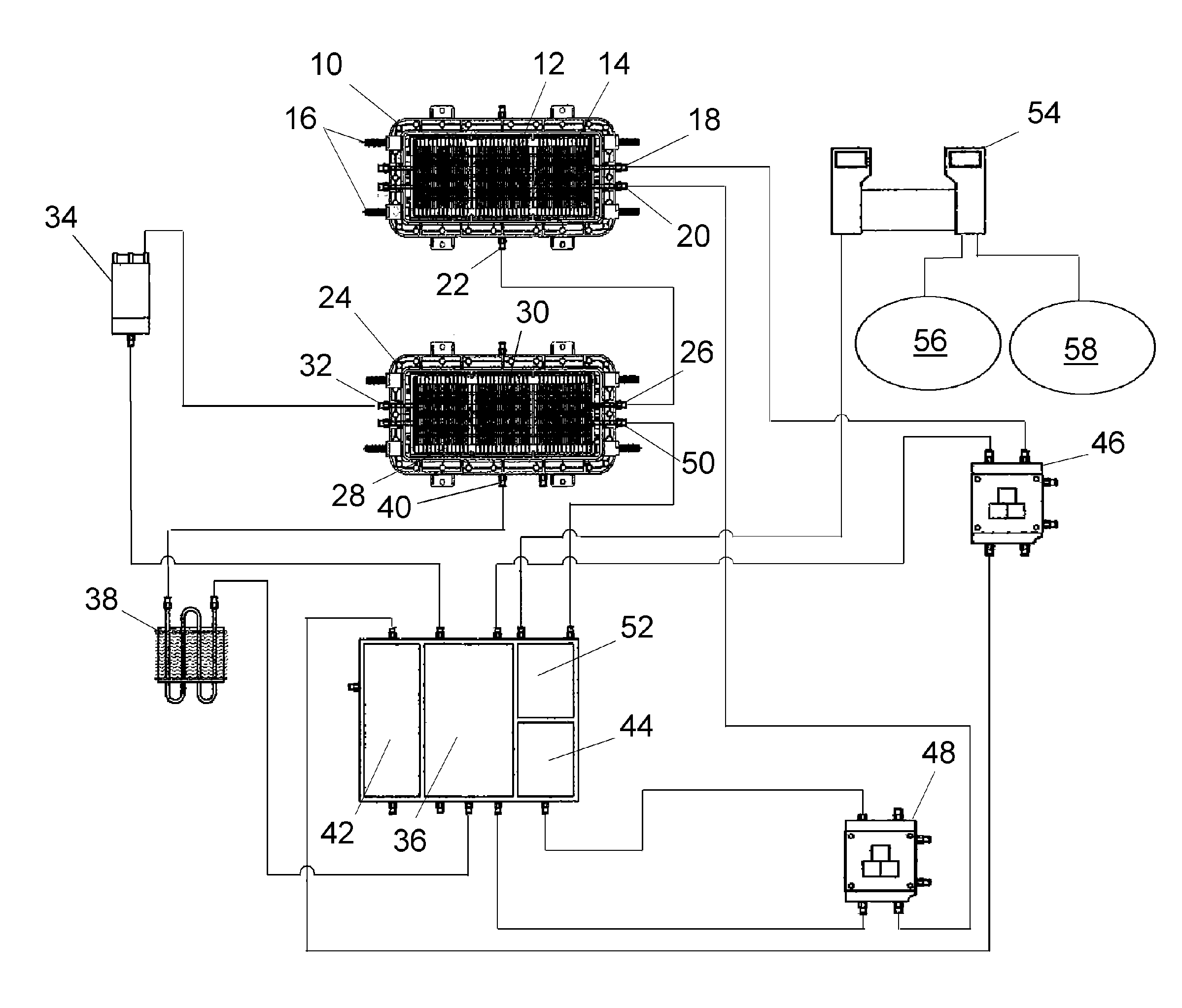

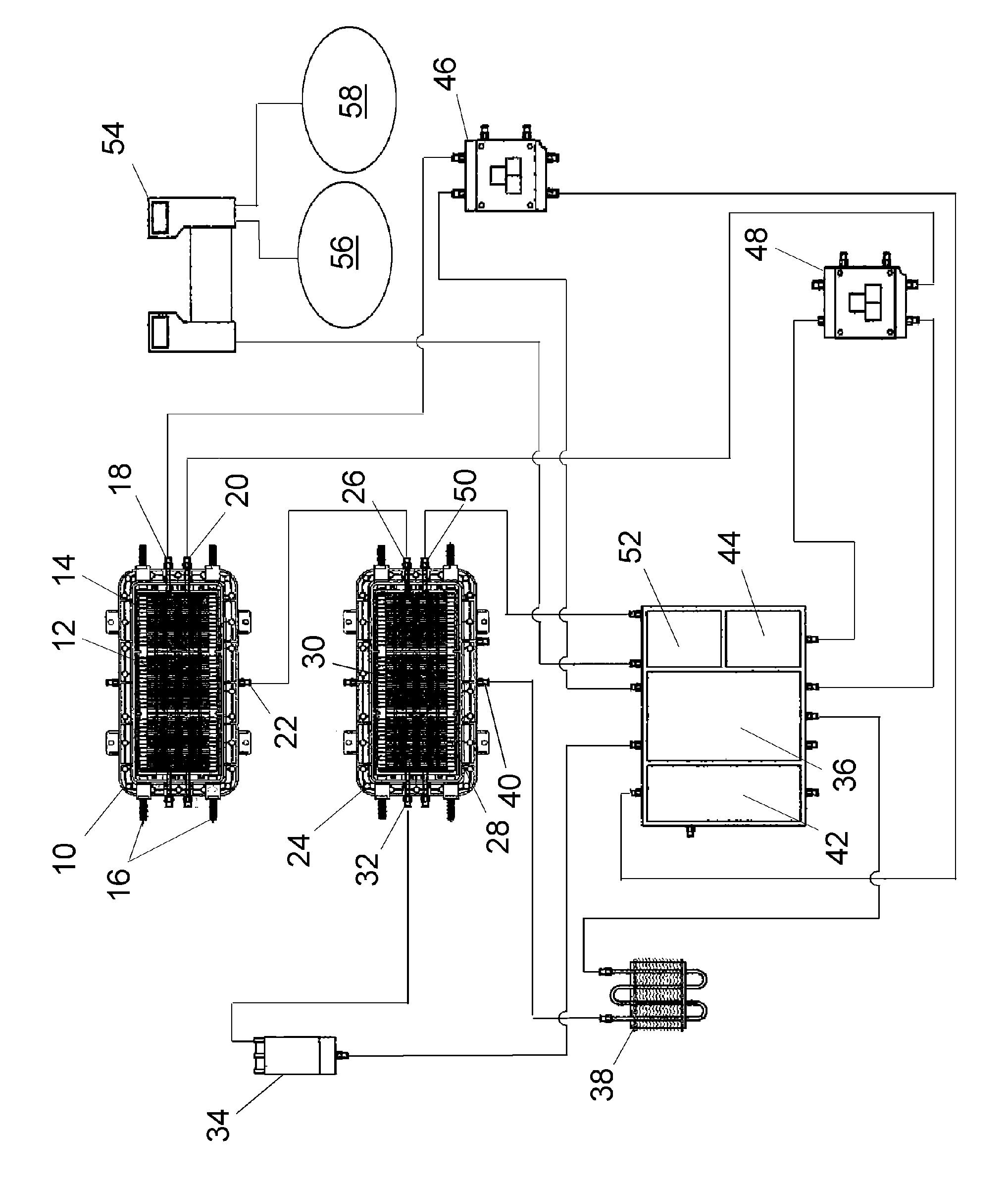

[0012]Turning to the schematic, a first closed vessel 10 includes an arrangement of anodes and cathodes 12 in a cavity 14. Neutral electrodes may also be used to match the impedance with the power source to maximize efficiency as may be empirically determined. The electrodes employed in the preferred embodiment are plates 12 of alternating polarity extending across the cavity 14. Stainless steel has been used but more exotic metals are known to increase plate longevity. Electrical feeds 16 conventionally communicate with the electrodes 12. This first closed vessel 10 contains a bath in the cavity 14 consisting essentially of water, electrolyte, and a thin layer of liquid hydrocarbon fuel. The electrolyte may be introduced as potassium hydroxide. The fuel may be any combustible hydrocarbon which would be liquid in the environment of the bath, most typically gasoline, diesel fuel or kerosene. The layer of liquid hydrocarbon fuel is sufficient to form an oxygen barrier above the water....

PUM

| Property | Measurement | Unit |

|---|---|---|

| polarity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com