Cnt-infused fiber and method therefor

a technology applied in the field of carbon nanotubes and fibers, can solve the problems of difficult separation of carbon nanotubes and direct application of carbon nanotubes to fibers, and achieve the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

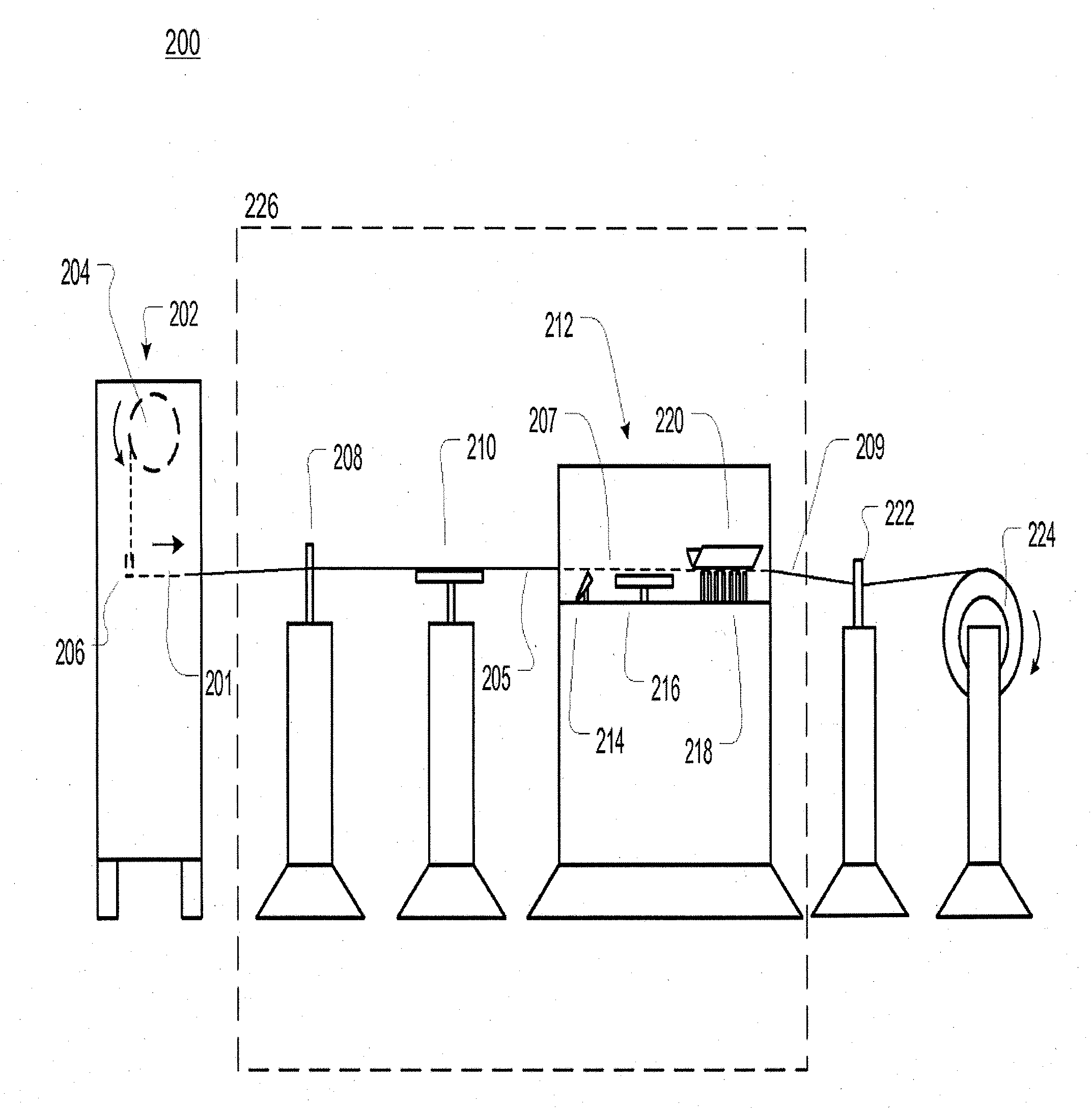

Method used

Image

Examples

example

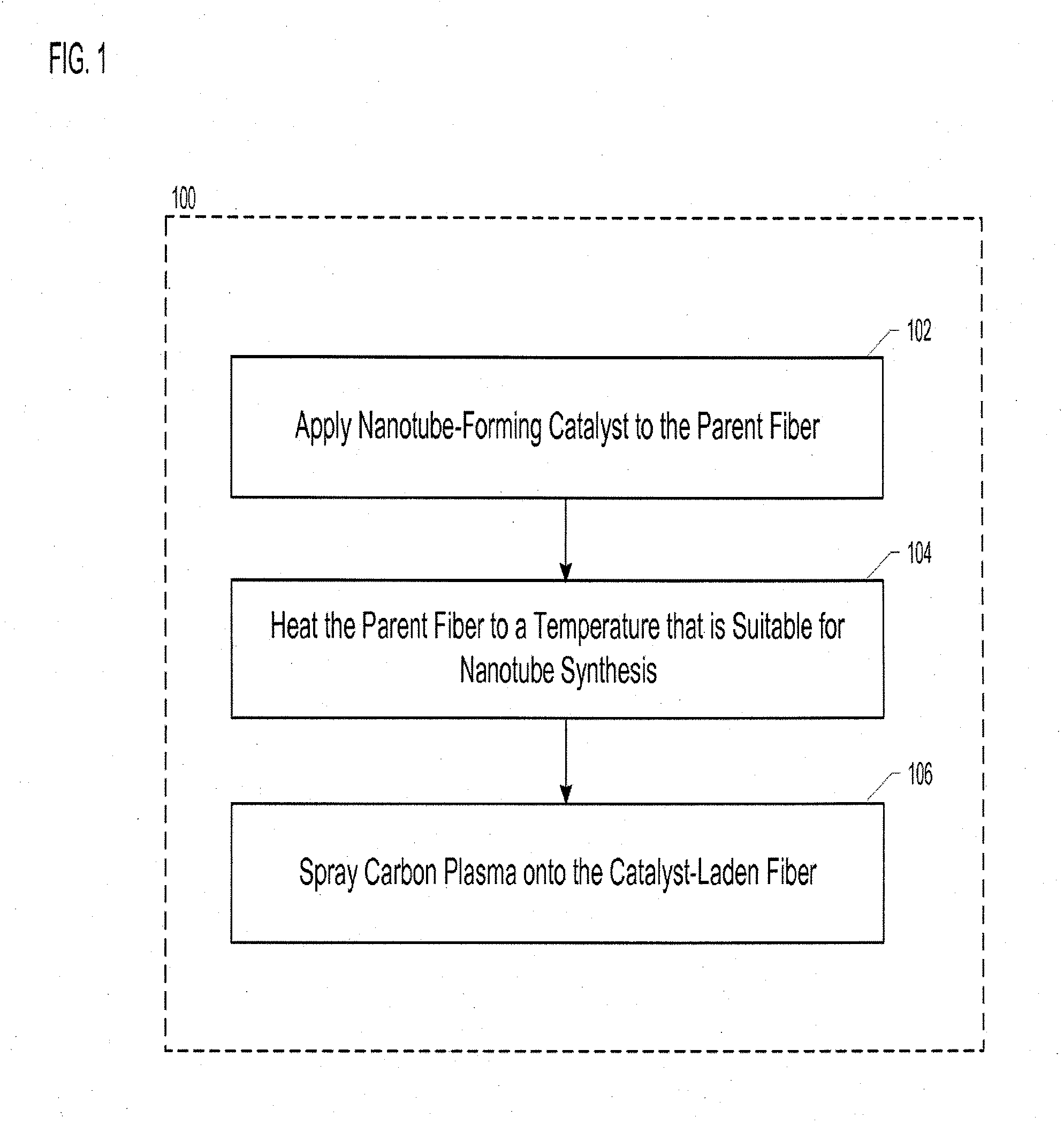

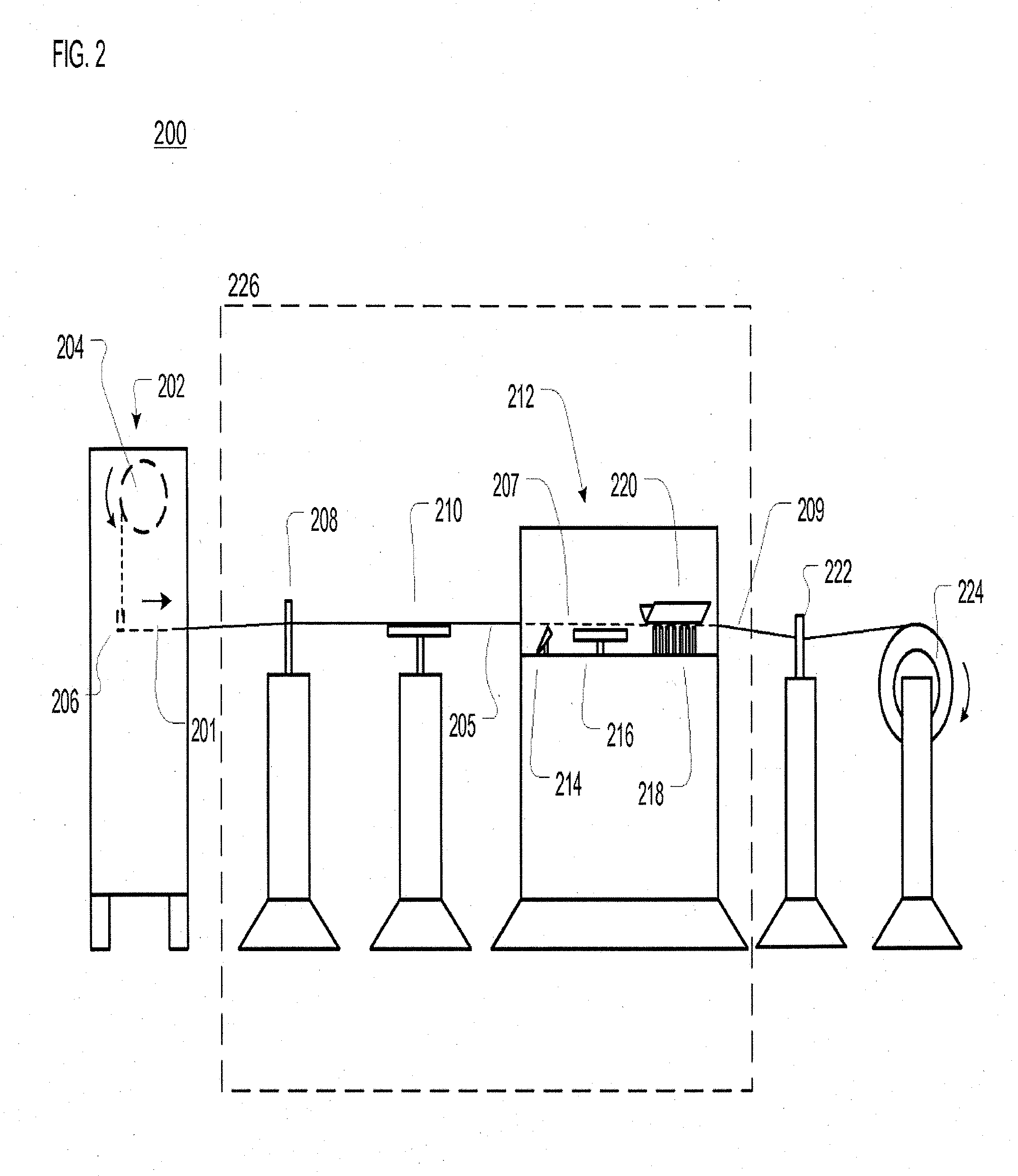

[0099]A CNT-infused carbon fiber was formed in accordance with the illustrative embodiment. A current was passed through carbon fiber (the parent fiber) to heat it to approximately 800° C. to remove epoxy sizing material. The fiber was then cooled to room temperature and left clamped between electrodes. A ferro-fluid catalyst was applied to the fiber using an aerosol spray technique. The fiber was allowed to dry and the chamber was closed, evacuated and filled with argon. A current was passed through the carbon fiber again to heat it to approximately 800° C. for carbon nanotube synthesis. A carbon plasma was generated from acetylene precursor using 13.56 MHz microwave energy using an atmospheric pressure plasma jet. The carrier gas in the plasma jet was helium at 20 standard liters per minute (slm) and the argon was provided at 1.2 slm. The plasma jet was fixtured to a robotic motion control system allowing the plasma jet to move over the length of the fiber at a speed between 6 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com