Surface light source device, lighting device, and backlight device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1-1

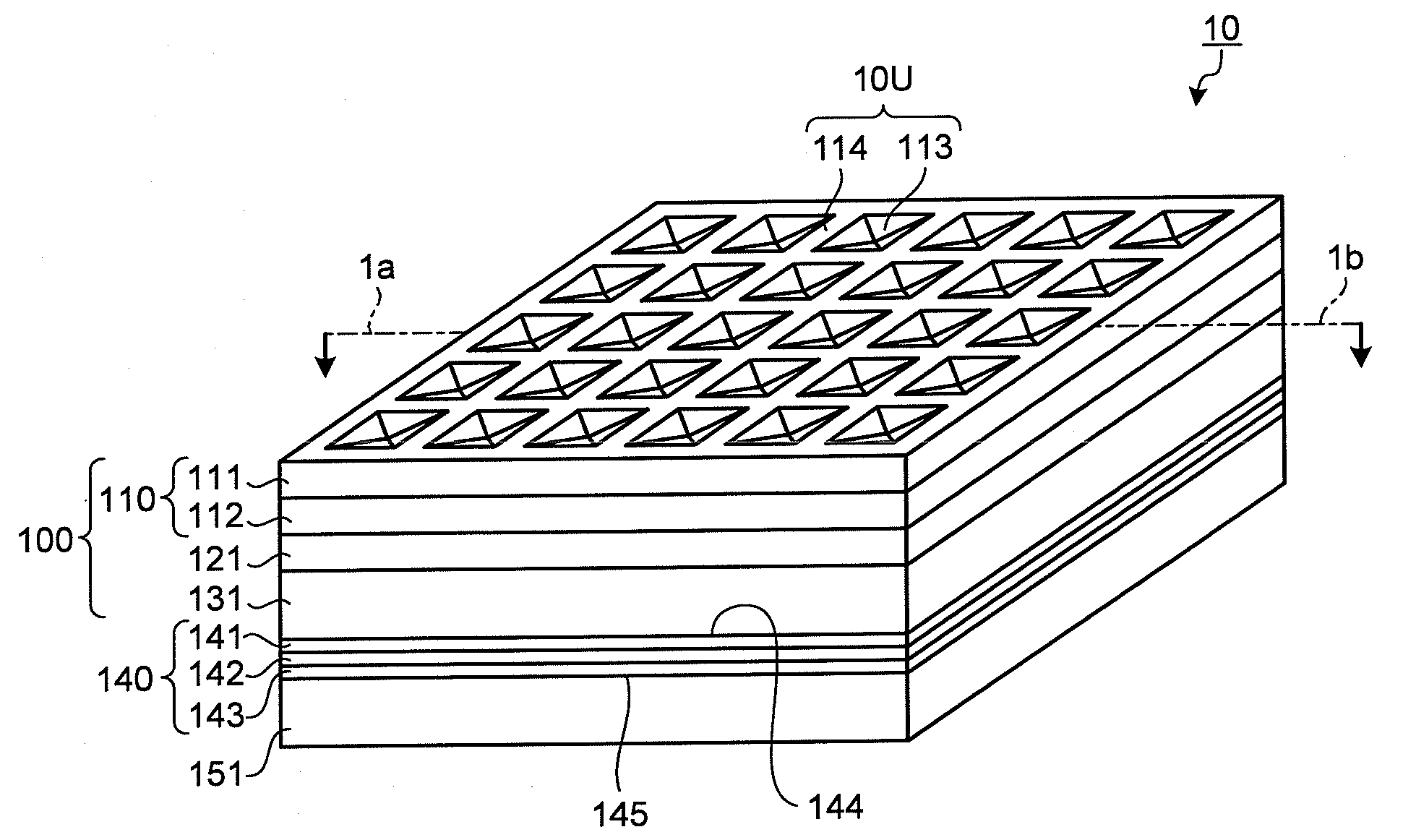

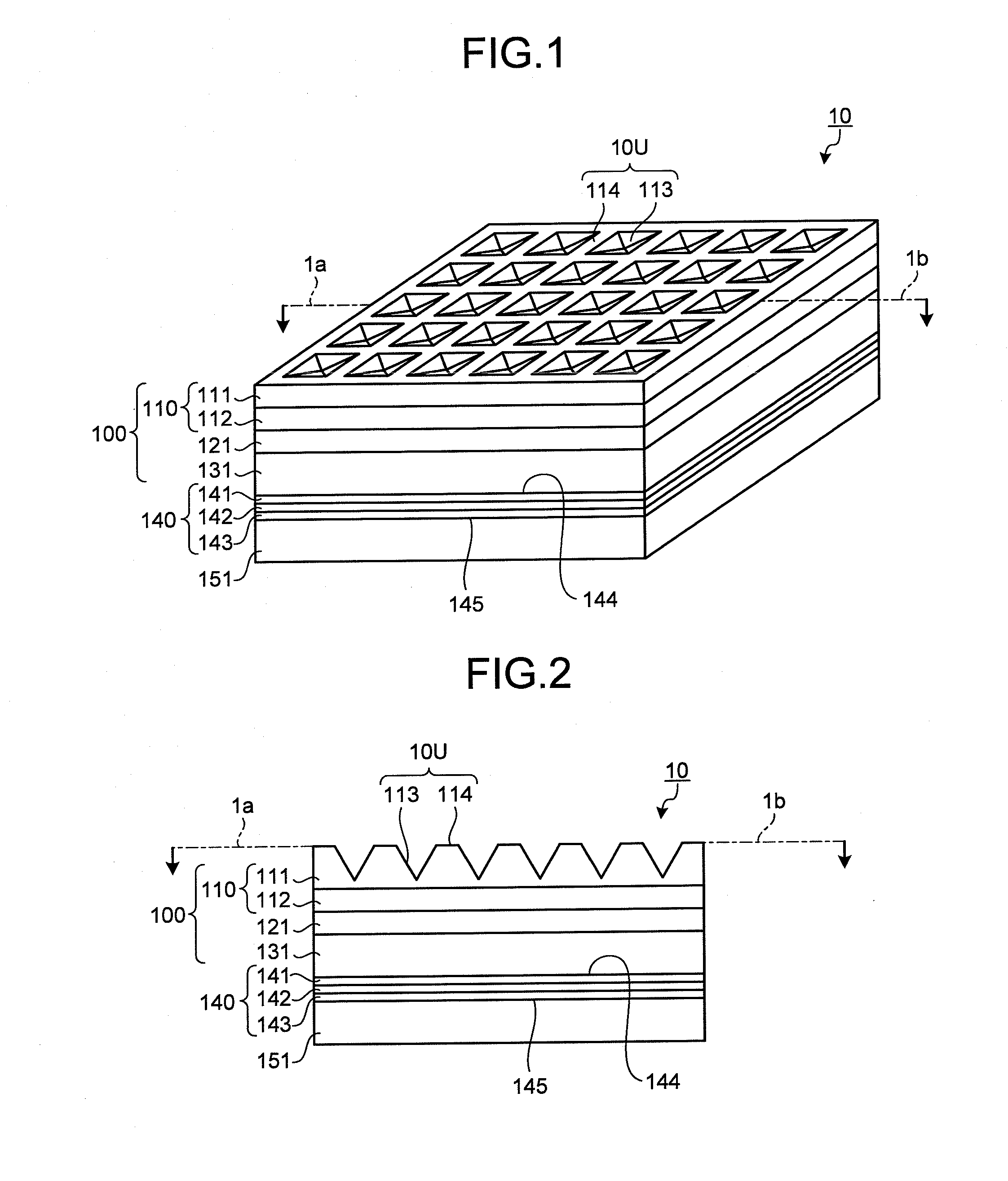

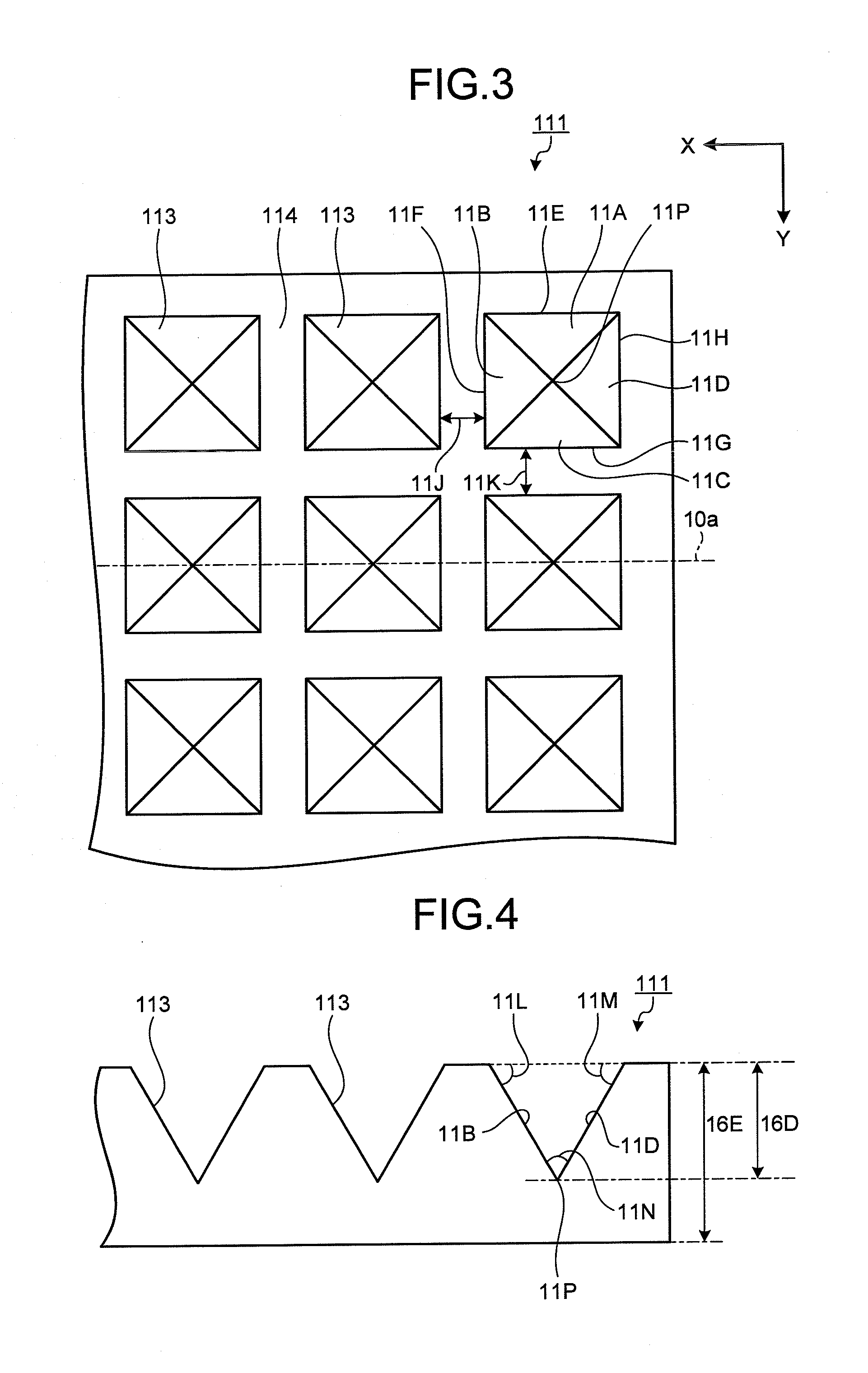

[0073]The first invention will be described in more detail with reference to the drawings.

[0074]A surface light source device of the first invention includes: an organic EL element including a luminescent layer; and a light-emitting surface structure layer that is disposed in contact with at least one surface of the organic EL element and defines a concave-convex structure on the surface on the device light-emitting surface side.

[0075]The device light-emitting surface is the light-emitting surface of the surface light source device, i.e., the light-emitting surface from which the light from the surface light source device is emitted to the outside of the device. The device light-emitting surface is a surface parallel to the luminescent layer of the organic EL element and is parallel to the principal surface of the surface light source device. However, in a microscopic sense, the surfaces of concave portions described later may form a non-parallel angle with respect to the luminescen...

embodiment 1-2

[0147]In the surface light source device of the first invention, the shape of the concave portions constituting the device light-emitting surface is not limited to the pyramid shape exemplified in Embodiment 1-1 described above. For example, the concave portions may have a shape that is part of a sphere as in Embodiment 1-2 which will be described below.

[0148]Embodiment 1-2 is a second embodiment according to the first invention. FIG. 7 is a top view schematically showing a surface light source device according to Embodiment 1-2, and FIG. 8 is a cross-sectional view showing a cross-section obtained by cutting the surface light source device shown in FIG. 7 along a plane that passes through line 2a in FIG. 7 and is perpendicular to the device light-emitting surface. As shown in FIGS. 7 and 8, the surface light source device 20 according to Embodiment 1-2 has the same configuration as that of Embodiment 1-1 except that the shape of the device light-emitting surface, i.e. the surface s...

embodiment 1-3

[0151]In the surface light source device of the first invention, the shape of the concave portions constituting the device light-emitting surface may also be a groove shape as in Embodiment 1-3 which will be described below.

[0152]Embodiment 1-3 is a third embodiment according to the first invention. FIG. 9 is a perspective view schematically showing the surface light source device according to Embodiment 1-3. As shown in FIG. 9, the surface light source device 30 according to Embodiment 1-3 has the same configuration as that of Embodiment 1-1 except that the shape of the device light-emitting surface, i.e. the surface shape of a concave-convex structure layer 311 in a multi-layered body 310 constituting a light-emitting surface structure layer 300, is different from that in the first embodiment.

[0153]Each of a plurality of concave portions 313 formed on the surface of the concave-convex structure layer 311 has a linear groove shape and includes two flat oblique surfaces. Therefore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com