Algal medium chain length fatty acids and hydrocarbons

a technology of applied in the field of algal medium chain length fatty acids and hydrocarbons, can solve the problems of increasing competition and price volatility for limited global supplies, inconvenient conversion of biodiesel produced from current available oil crop-based feedstocks and commercial processes, and increasing burden on the us economy, etc., to achieve the effect of convenient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0156]A general process diagram of the proposed algae-based jet fuel production technology is shown in FIG. 14.

[0157]In various non-limiting examples, the following processes can be carried out in conjunction with algae-based medium chain length fatty acid production:[0158]Production of algal feedstock using a number of selected algal species grown in one or more photobioreactors of same or different designs. Each selected algal species will produce large quantities of oil enriched with one or more medium-chain length fatty acids / esters.[0159]Oil-rich cells are harvested and dried in a form of algal flour.[0160]Algal flour is subjected to solvent extraction using a chemical extraction method. A supercritical liquid extraction method can also be employed as an alternative.[0161]Resulting algal oil is subjected to a deoxygenating / hydroxylation process to convert algal oil to hydrocarbons.[0162]A separation / refining technology separates and concentrates desirable hydrocarbon fractions ...

example 2

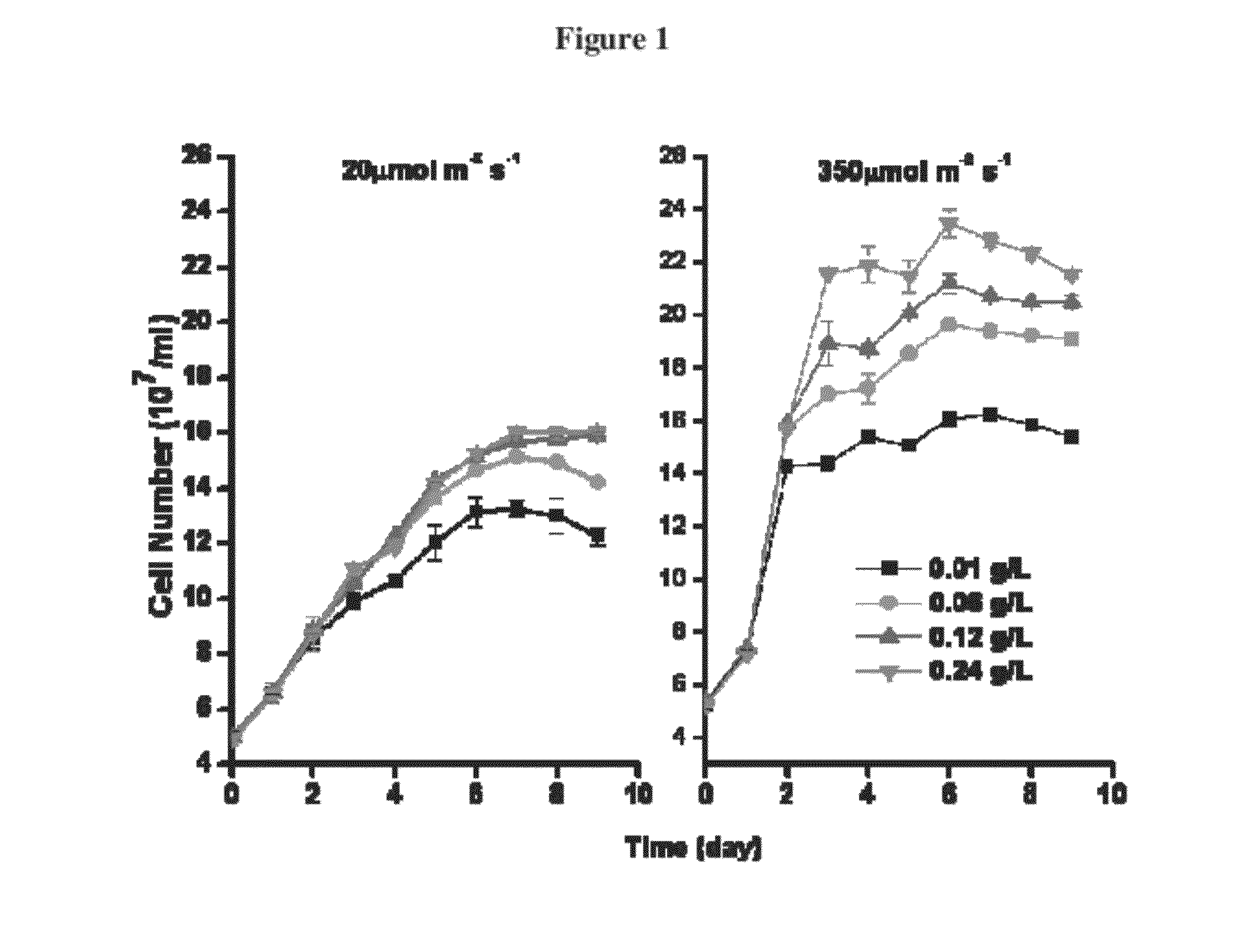

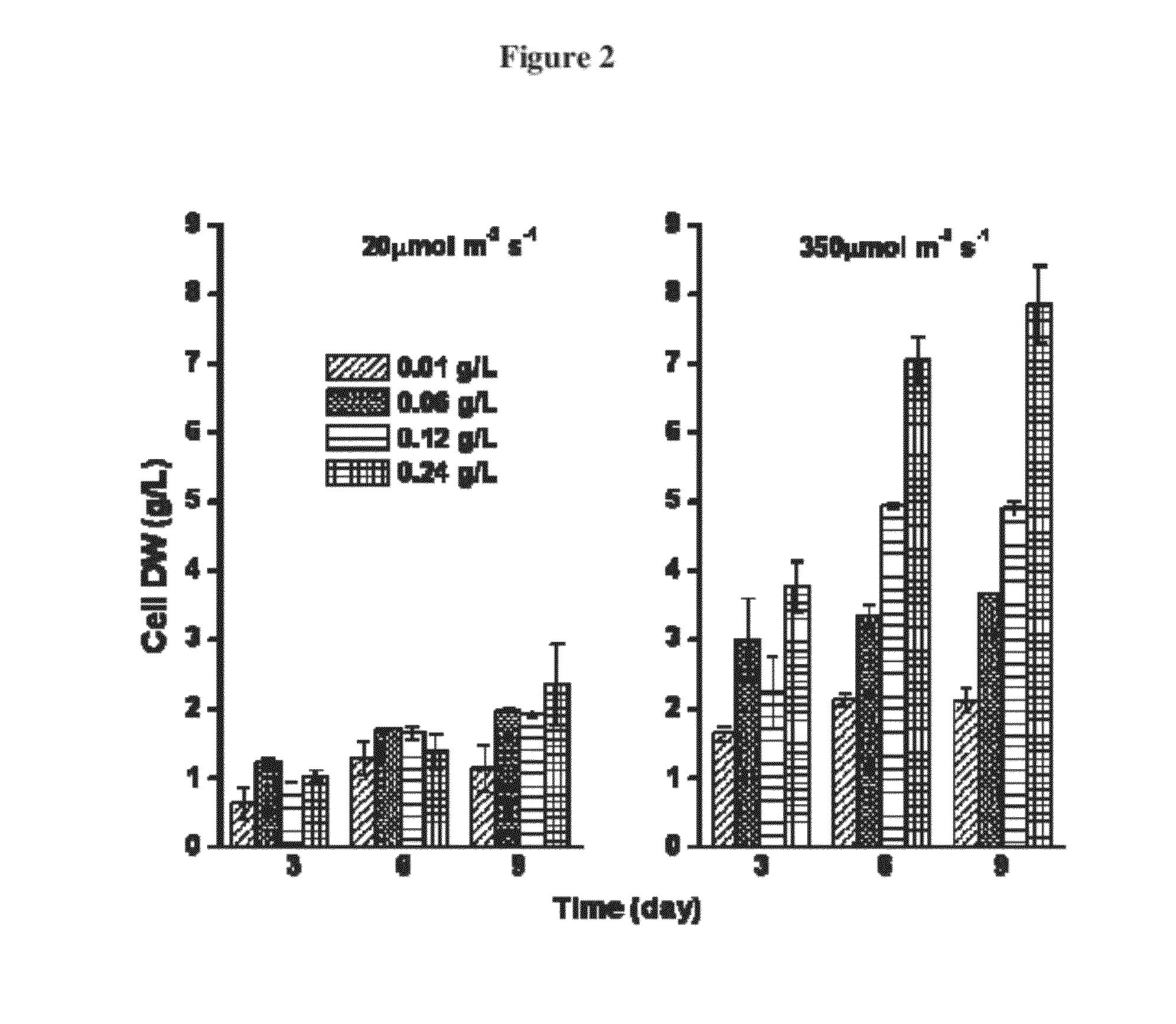

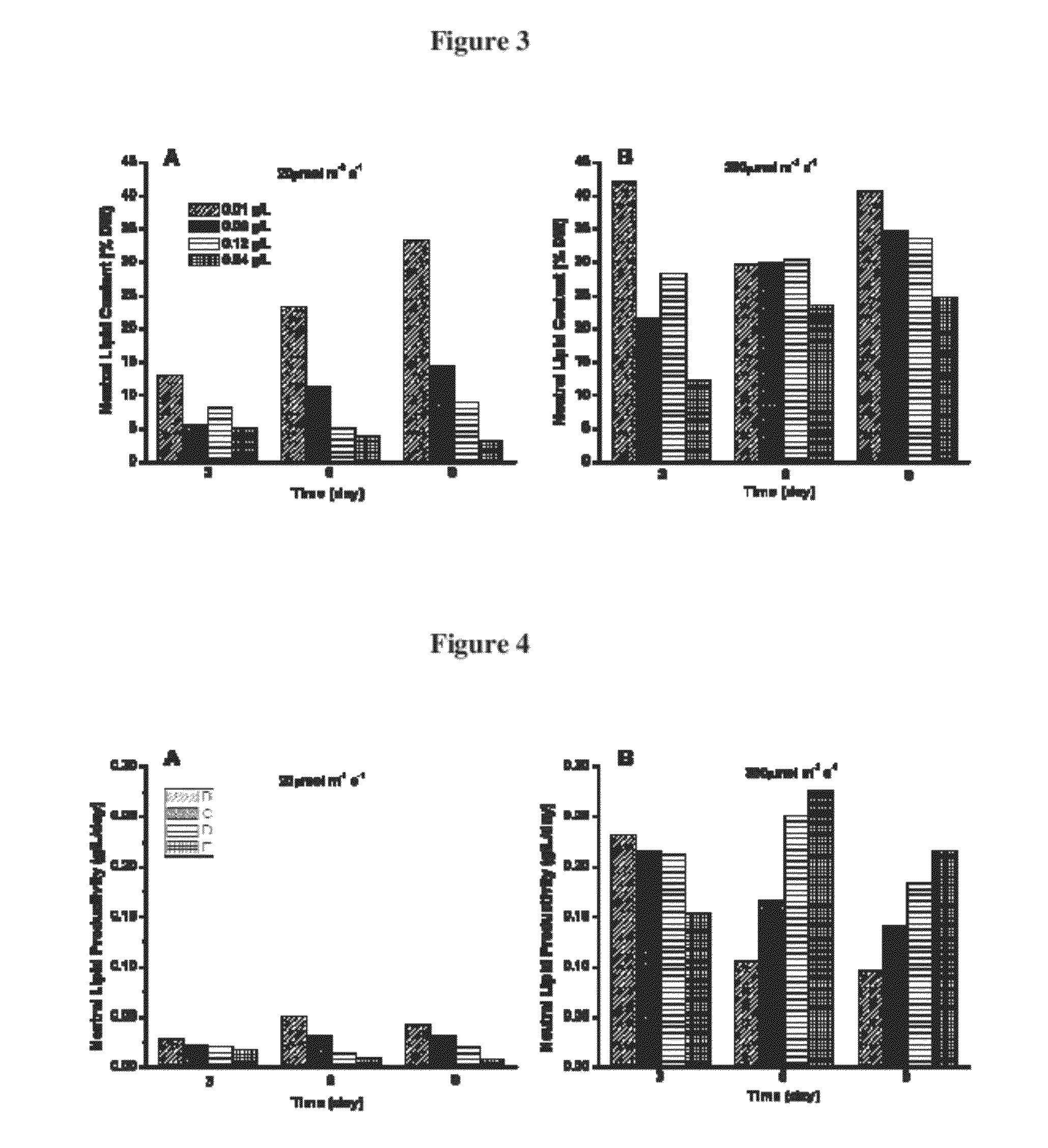

[0167]The inventors have performed screening for medium-chain oil-producers from numerous algal species / strains isolated by and maintained in their laboratory. One of the algal strains tested is a marine alga Nannochloropsis LARB-AZ 0202.0 ATCC Number PTA-11048 and mutants thereof (LARB-AZ 0202.2 ATCC Number PTA-11049 and LARB-AZ 0202.3 ATCC Number PTA-11050, which have the ability to produce lipids enriched with C16 fatty acid, which can make up at least 50% to 60% of total fatty acids produced in the cell. LARB-AZ 0202.0 is a Nannochloropsis strain that was originally isolated by Qiang Hu from the Red Sea near Eilat, Israel in March 2007. The algal strain was isolated using a standard agar plating approach and has been since maintained in F / 2 artificial culture medium at room temperature and continuous illumination of ca. 20 μmol m−2 s−1.

[0168]GC / MS analysis of the fatty acid composition of Nannochloropsis strain LARB-AZ 0202.0 showed that the medium chain fatty acids (C14 and C16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| freezing points | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com