Apparatus and method for treating impurities in air and materials

a technology of air and impurities, applied in the field of air treatment apparatuses and air treatment methods, can solve the problems of odor and/or damage to equipment, large equipment pieces, and difficult washing and drying, and achieve the effects of enhancing the reaction of ozone with ethylene or other organic gases, maximizing benefits, and improving the efficiency of air cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064]Throughout this specification and in the claims, the terms air cleaning unit and atmosphere treating unit are intended to relate to an apparatus for sanitizing, decontaminating, deodorizing, conditioning, drying and / or otherwise treating, cleaning, modifying and / or improving an atmosphere within a container.

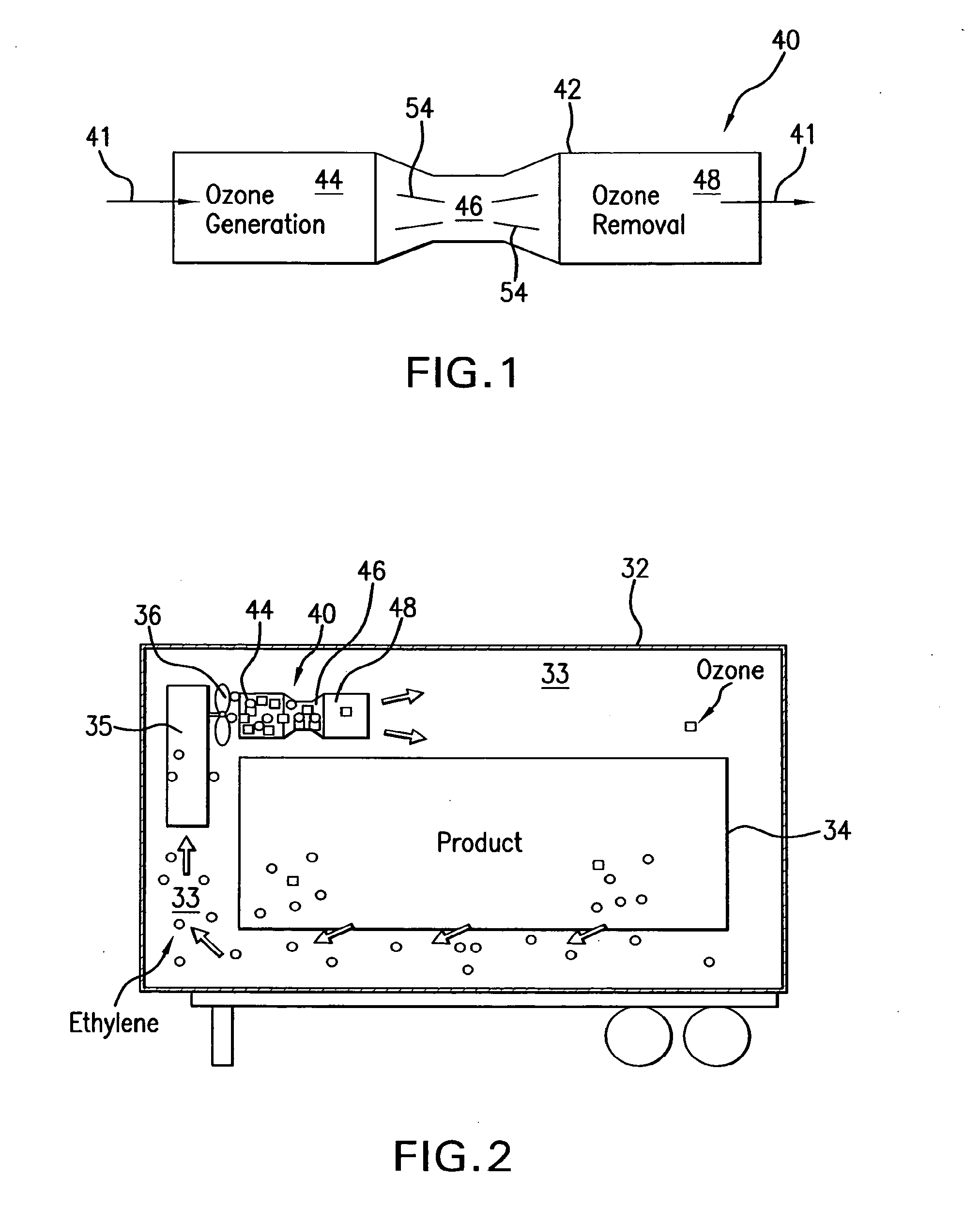

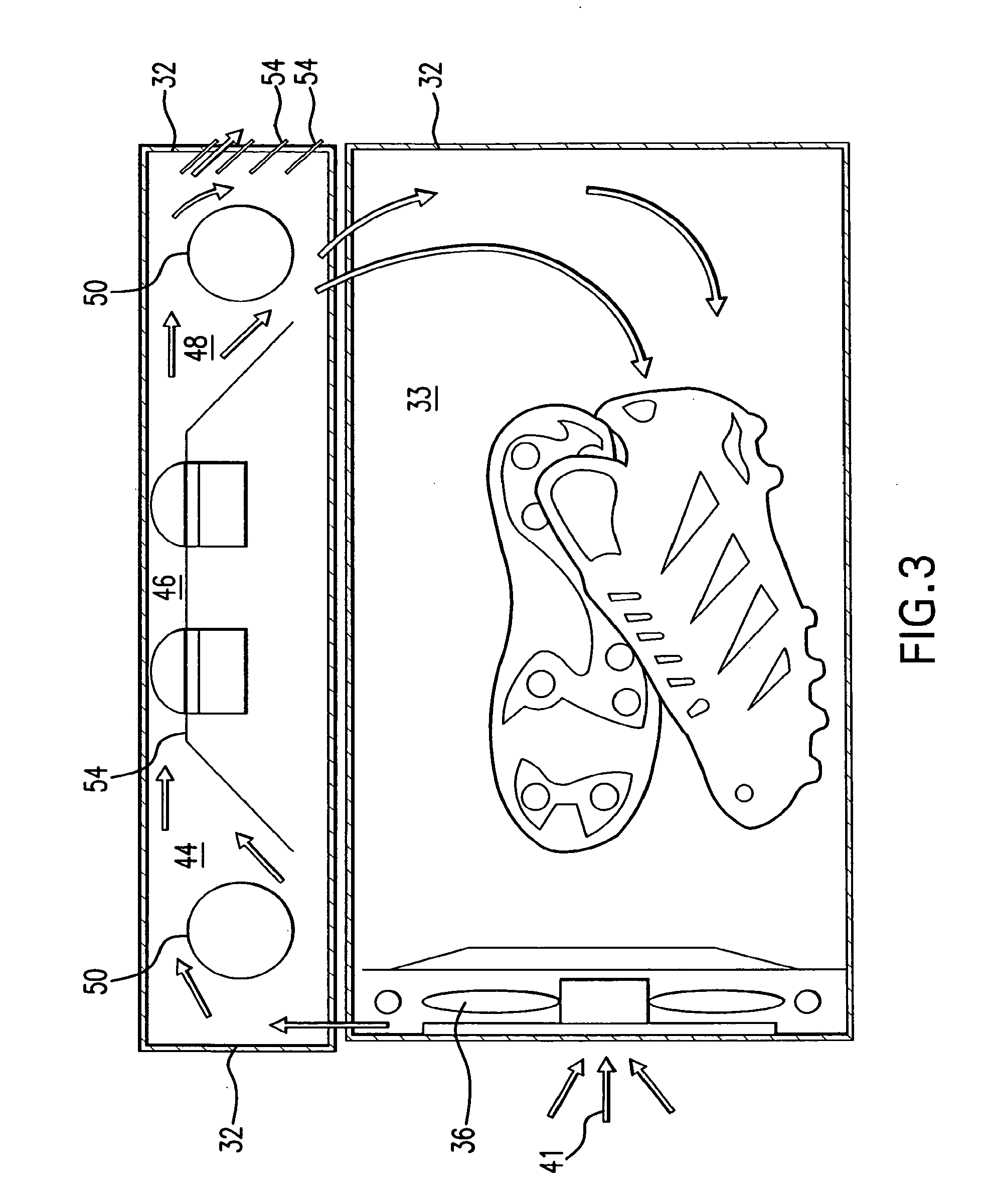

[0065]FIG. 1 shows air cleaning unit 40, according to one embodiment of this invention. FIG. 2 shows air cleaning unit 40 positioned or mounted within container 32, such as a truck trailer, according to one embodiment of this invention. FIG. 3 shows air cleaning unit 40 positioned or mounted within a different container 32, according to another embodiment of this invention.

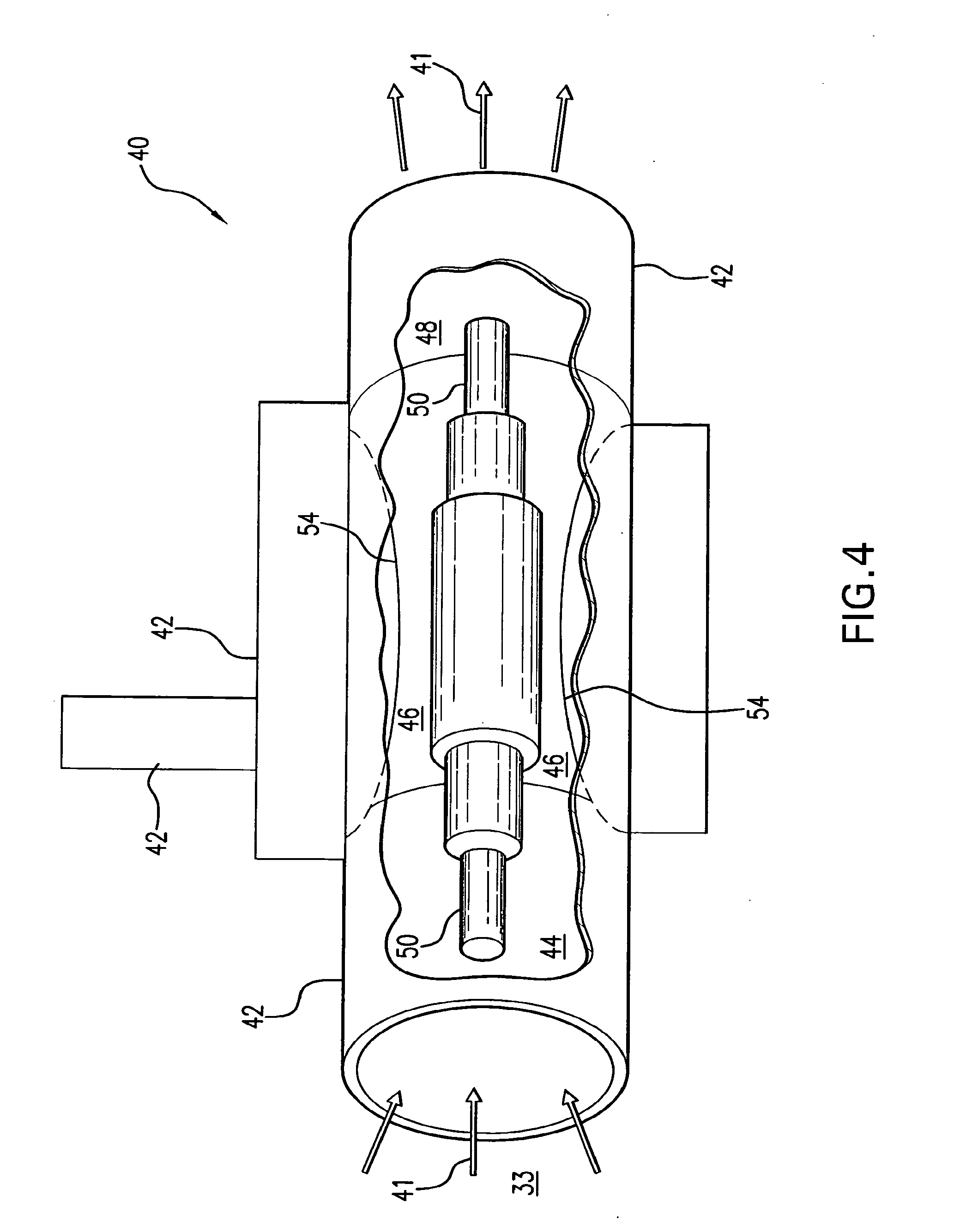

[0066]As shown in FIG. 1, air cleaning unit 40 has structure 42, such as a housing, that forms zone 44, zone 46 and zone 48. As air or another suitable atmosphere passes through air cleaning unit 40, such as shown by the arrows of flow direction 41, in FIG. 1, atmosphere 33 passes first through zone 44, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com