Multilayer component for the encapsulation of a sensitive element

a multi-layer component and element technology, applied in the field of multi-layer components for encapsulating elements, can solve the problems of reducing the resistance of multi-layer electronic devices, and reducing the resistance of transparent electrodes, etc., to achieve the effect of improving the resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

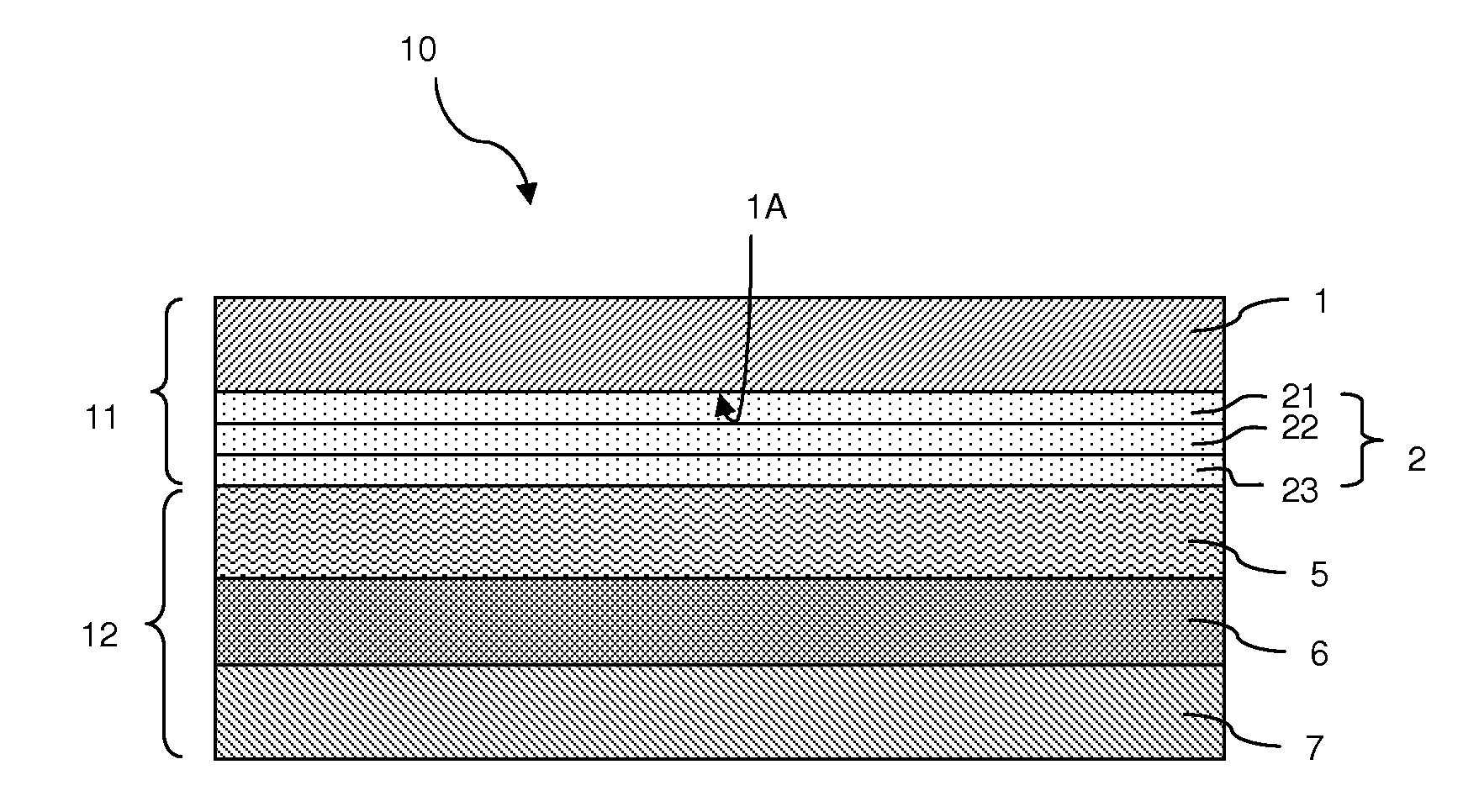

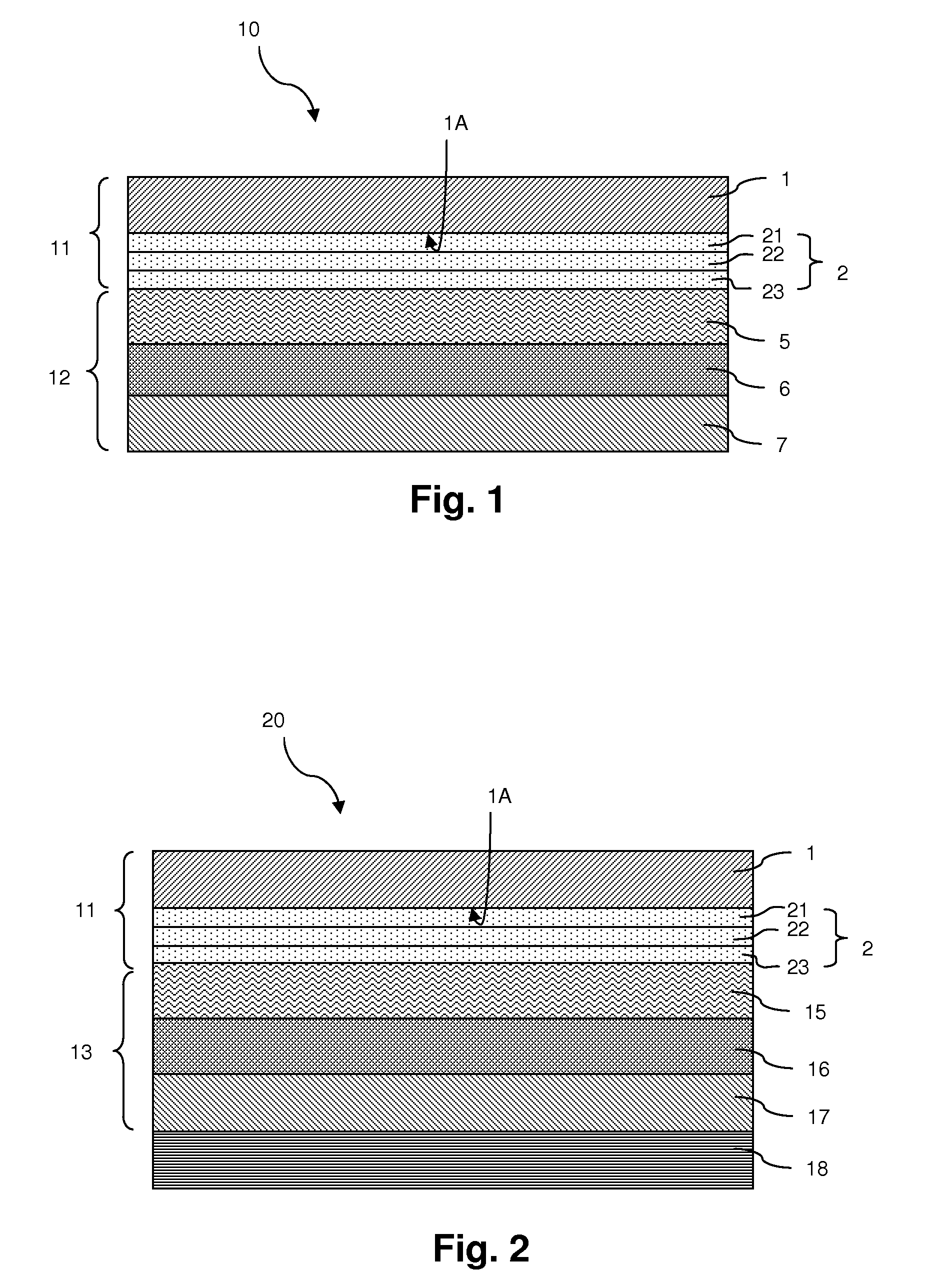

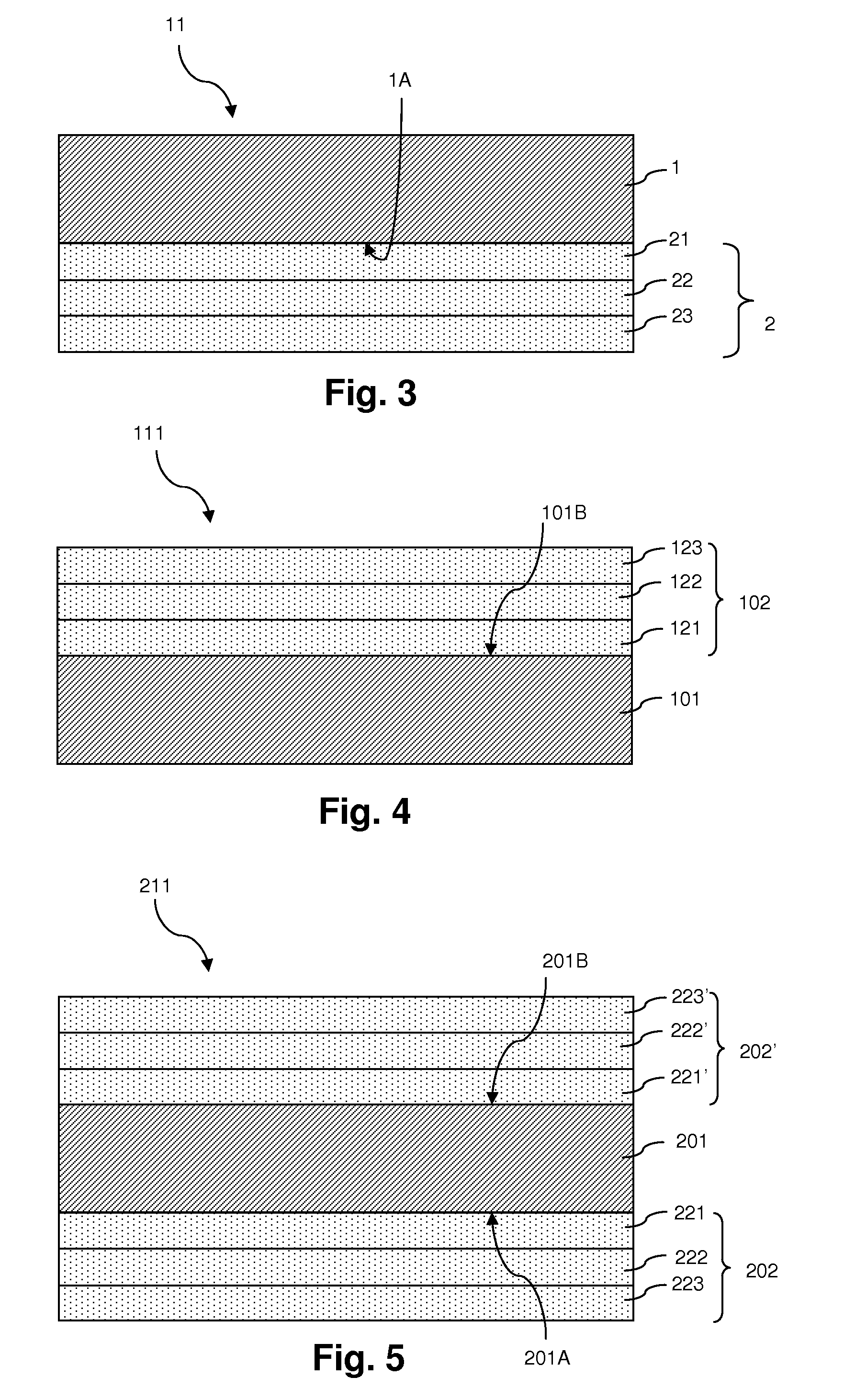

Image

Examples

examples

[0093]Examples of barrier stacks, deposited on a flexible substrate made of polyethylene terephthalate with an interfacial layer on the barrier deposition surface of the substrate (herein denoted “PET”) having a geometric thickness of 0.125 mm, are given in Table 1 below. In an embodiment, the interfacial layer is a UV-cured acrylate layer having a thickness between approximately 1 to 10 microns, preferably 4 to 5 microns. The interfacial layer planarizes and smoothens the polyethylene terephthalate surface.

[0094]The properties of the stacks given in Table 1 are the following:[0095]TL: % light transmission in the visible, measured under illuminant D65 / 2° observer conditions;[0096]RL: % light reflection in the visible, measured under illuminant D65 / 2° observer conditions;[0097]A: % light absorption in the visible, such that:

TL+RL+A=1;[0098]WVTR (water vapor transfer rate): water vapor transmission rate in g / m2.day, measured using the MOCON AQUATRAN system at 37.8° C. and 100% relativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com