Coating agents and coated articles

a coating agent and coating technology, applied in the field of coating agents and coated articles, can solve the problems of difficult modification of silicone surfaces, hostile environment of human body, etc., and achieve the effect of facilitating the use of additional coating “layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Photo-Poly(octadecene-alt-maleic anhydride)silane—(Photo-POMAS)

[0149]Five grams of poly(octadecene-alt-maleic anhydride), (MW 30,000-50,000, Aldrich, Milwaukee, Wis.), 0.5 g of 4-aminobenzophenone (Aldrich) and 0.08 g 4-dimethylaminopyridine (Aldrich) were dissolved in 100 mL chloroform and refluxed under argon for 2 hours. A 5 ml aminopropyl methylbis(trimethylsiloxy)silane portion was then added to the reaction mixture and refluxed for another 2 hours. The resulting solution was washed three times with 2N HCl, followed by three washes with deionized water. The sample was dried over anhydrous Na2SO4. After vacuum filtration, the filtrate was concentrated to dryness on a rotavap to yield 7.5 g of solid material.

[0150]The polymer product was characterized by 1H NMR (δ 0.0 ppm, CH3—Si; δ 0.8-1.5 ppm, alkyl protons; δ 2.5-3.5 ppm, CH—C═O; δ 7.4-7.6 ppm, aromatic protons) and FT-IR (C═O: 1710 cm−1; benzophenone: 1593 cm−1; Si—CH3: 1258 cm−1, 843 cm−, 755 cm−1; Si—O—Si: 1052...

example 2

Coating of Silicone Tubing with Photo-POMAS

[0151]A 7.5 g amount of the Photo-POMAS polymer, prepared as previously described in Example 1, was dissolved in 100 ml of IPA. Five pieces of 10 cm silicone tubing (DOVER™ silicone catheter, Covidien) were prepared for coating with the polymer by cleaning with a brief hand-rub of isopropanol. The silicone tubing pieces were coated with the Photo-POMAS / IPA solution by immersing the pieces in the solution for 30 seconds, then extracting the pieces of tubing from the coating solution at 0.5 cm / sec. The pieces were air dried at room temperature for 3 minutes, then irradiated with ultraviolet light (Harland Medical UVM400, Eden Prairie, Minn.) (300 to 400 nm) for 1 minute at a distance of 15 cm from the light source.

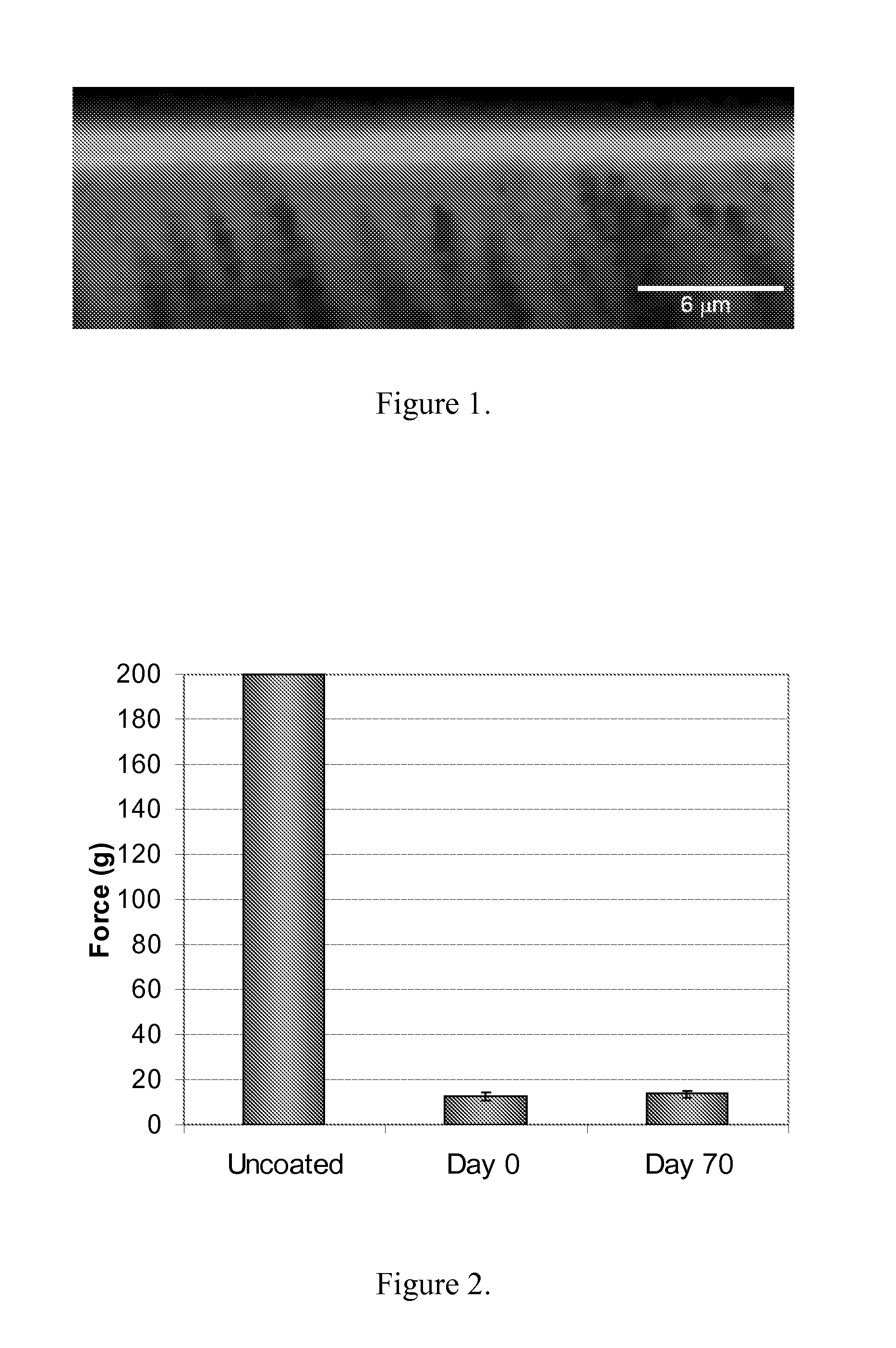

[0152]The photo-POMAS coating on the silicone tubing was characterized by SEM and Confocal Raman Microscope (FIG. 1). A uniform coating was confirmed. In FIG. 1, confocal Raman microscopy revealed a uniform coating on silicone cathe...

example 3

Lubricious Coating

[0153]The Photo-POMAS coated tubing pieces prepared in Example 2 were coated with Lubricent™ 460 by immersing the Photo-POMAS coated pieces in a Lubricent™ solution for 30 seconds, then extracting the Photo-POMAS and Lubricent™ coated silicone tubing at 0.5 cm / sec. The coated silicone pieces were air dried at room temperature for 3 minutes, then irradiated with ultraviolet light (300 to 400 nm) at 15 cm for 3 minutes. Silicone tubing coated with Lubricent™ without the Photo-POMAS polymer primer coating layer was used as a control.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Noncovalent bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com