Synthesis gas method and apparatus

a synthesis gas and gas technology, applied in the direction of products, organic chemistry, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of degrading the reform catalyst used in connection, the conventional method of producing a synthesis gas such as the one discussed above, and the production of synthesis gas is not optimal, so as to reduce the slip of methane and increase the equilibrium temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

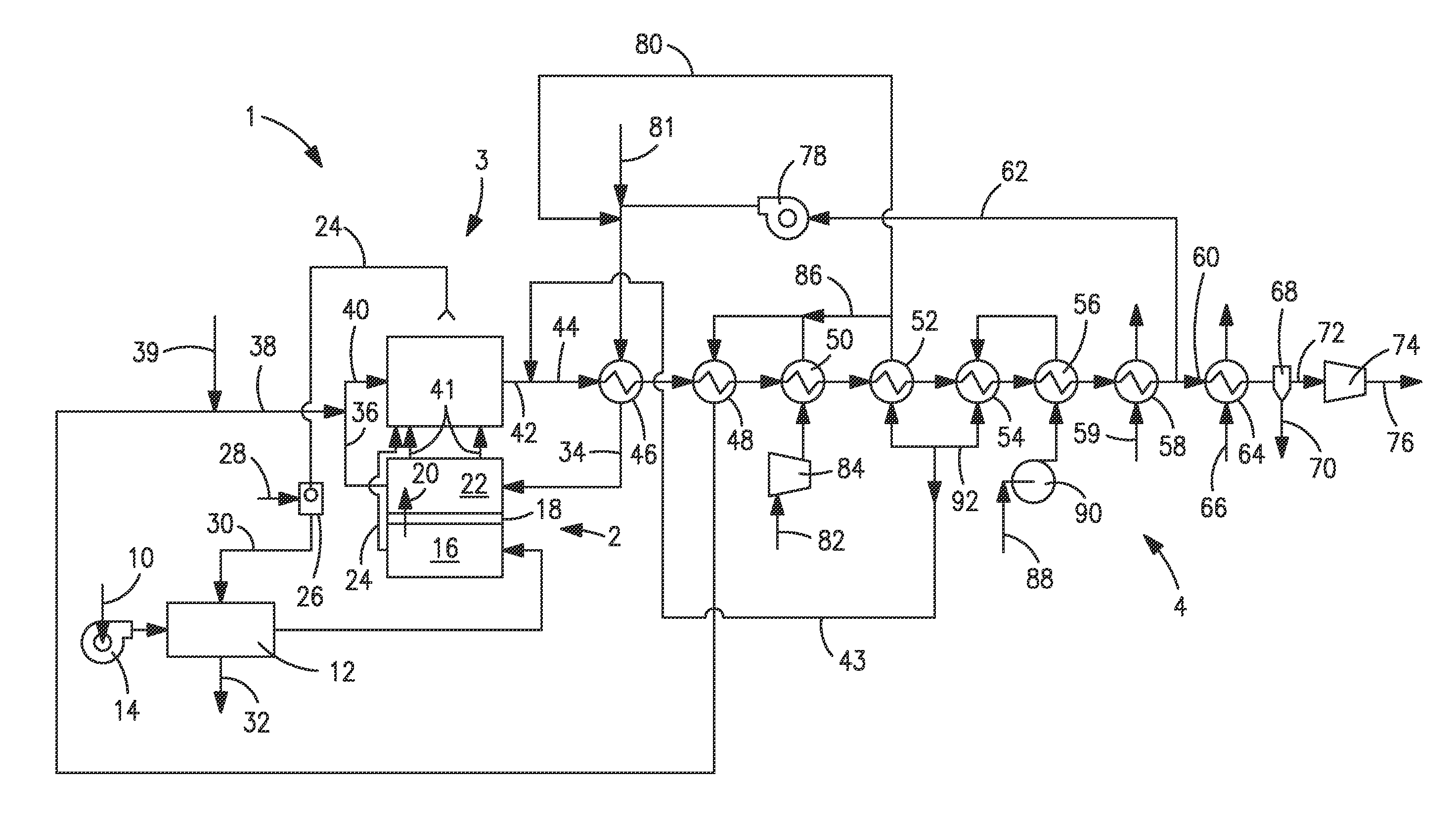

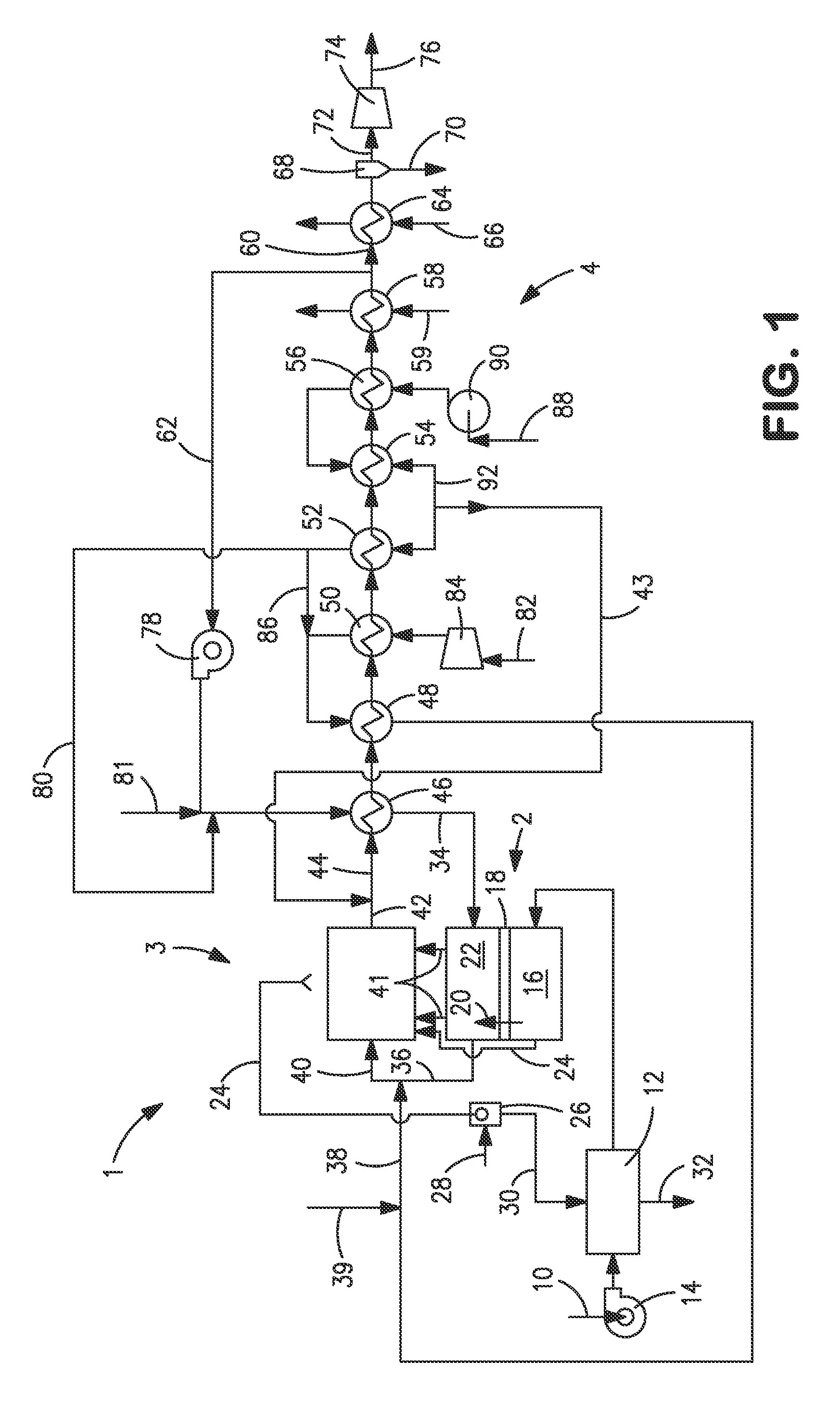

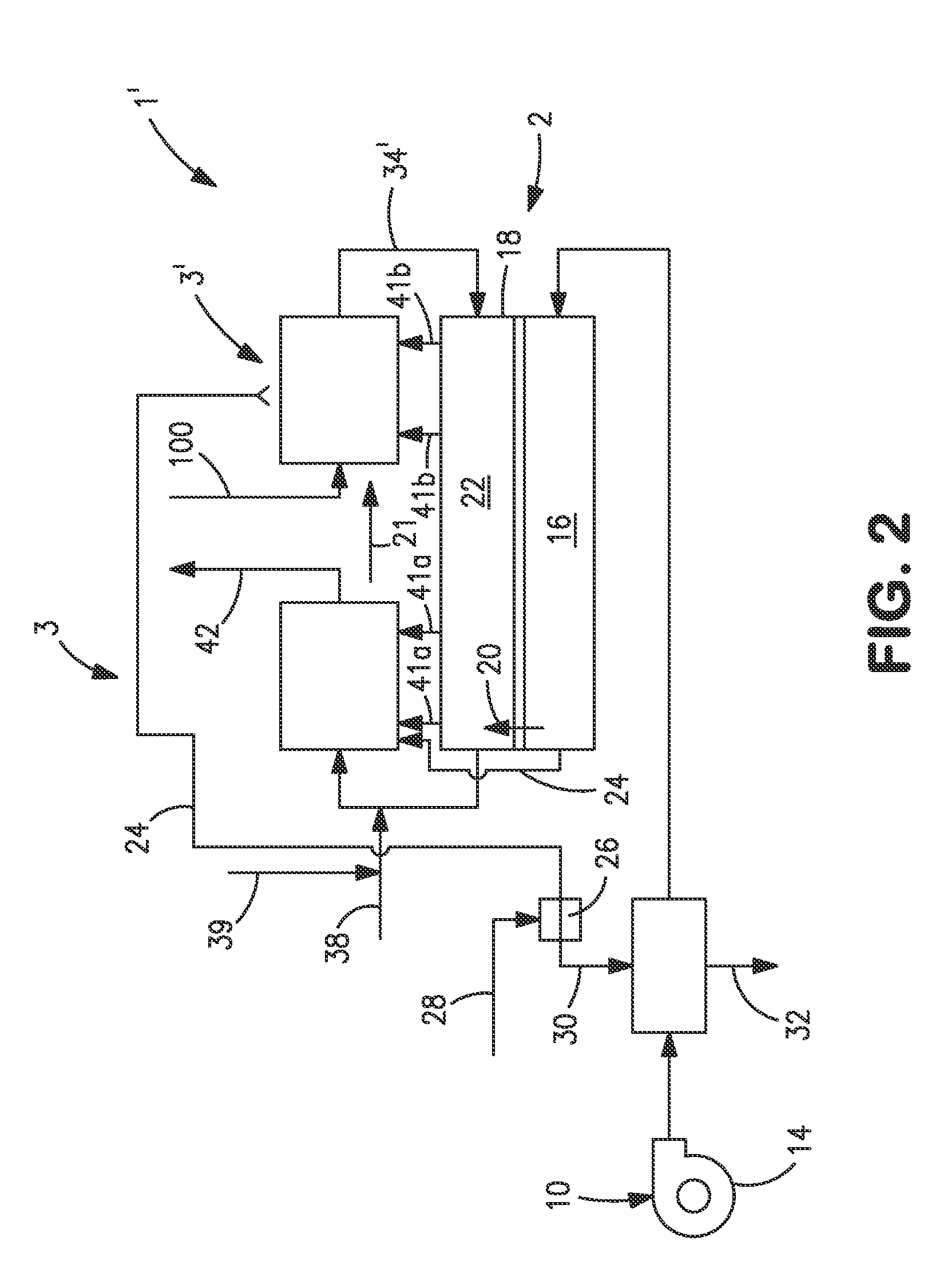

[0040]With reference to FIG. 1, an apparatus 1 is illustrated that is designed to produce a synthesis gas product through the steam methane reforming of hydrocarbons. Apparatus 1 includes one or more oxygen transport membrane elements of which oxygen transport membrane element 2 is illustrated. Oxygen transport membrane element 2 supplies heat by radiation and convective heat transfer to supply the endothermic heating requirements of a catalytic reactor 3 within which the hydrocarbons and steam are reacted to produce a synthesis gas. As well known in the art, at high temperatures, from 700 to 1100° C., steam will react with methane to yield a synthesis gas that contains hydrogen and carbon monoxide. Catalytic reactor 3, as would be known in the art, contains a catalyst, typically nickel, to promote such steam methane reforming reaction. Additionally, water-gas shift reactions occur in which the carbon monoxide will react with the steam to produce carbon dioxide and hydrogen. Althoug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com