Antireflective silica coatings based on sol-gel technique with controllable pore size, density, and distribution by manipulation of inter-particle interactions using pre-functionalized particles and additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

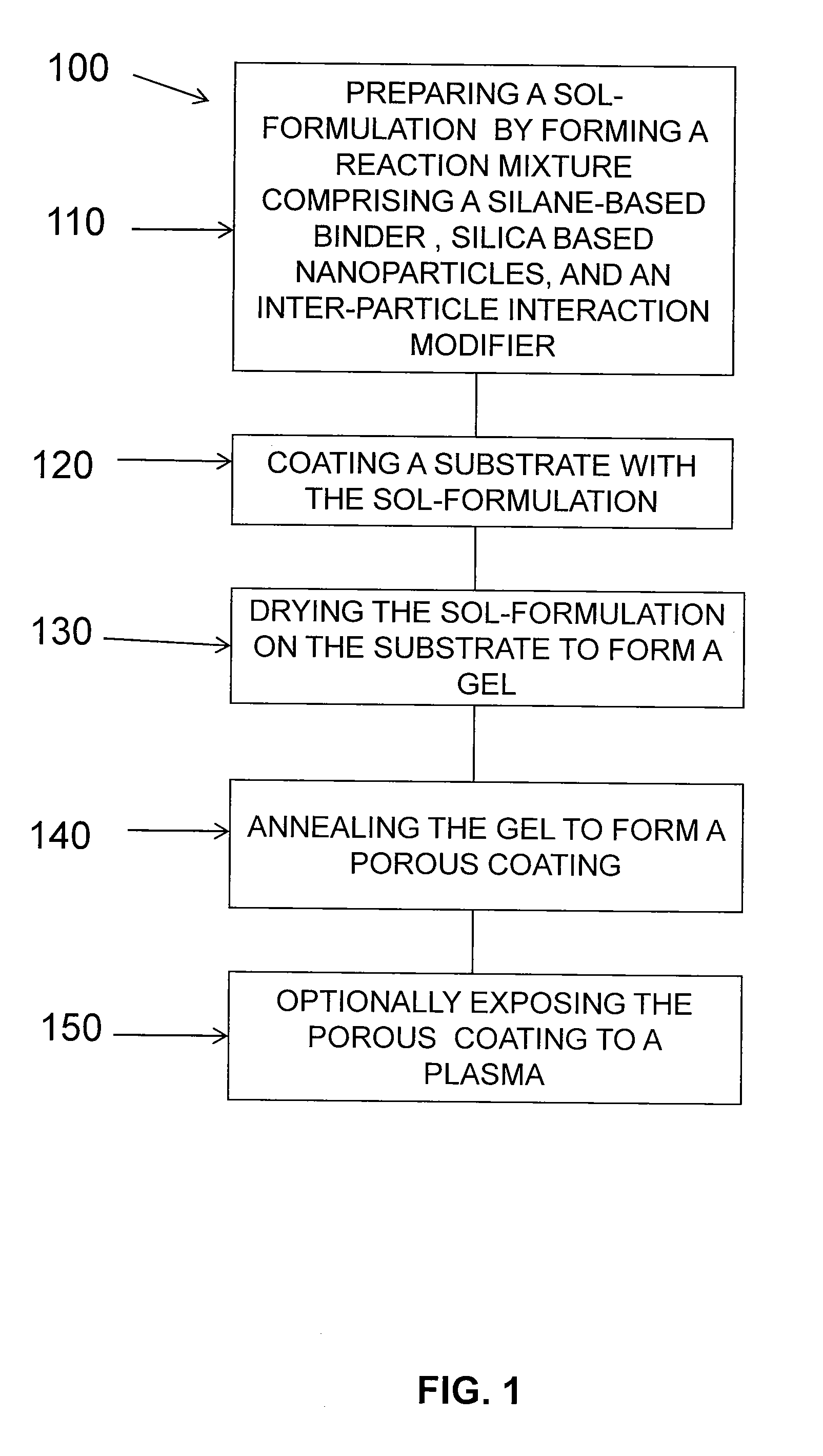

Method used

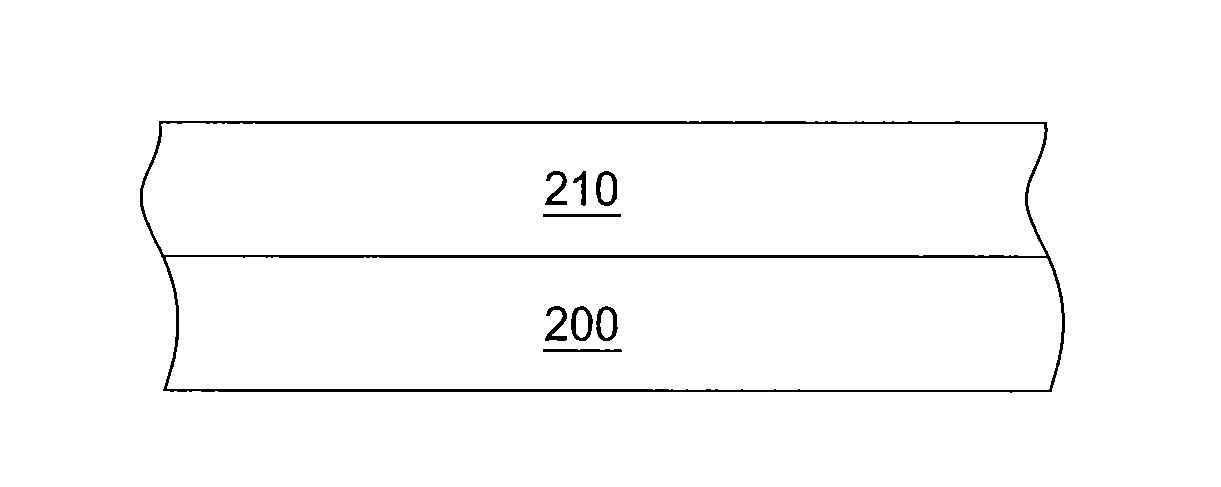

Image

Examples

examples

[0065]It is believed that the following examples further illustrate the objects and advantages of the embodiments. The particular materials and amounts thereof, as well as other conditions and details, recited in these examples should not be used to limit embodiments described herein. Unless stated otherwise all percentages, parts and ratios are by weight. Examples of the invention are numbered while comparative samples, which are not examples of the invention, are designated alphabetically.

example # 1

Example #1

[0066]A sol-formulation is prepared using tetraethylorthosilicate (TEOS) as the binder, n-propanol as the solvent, acetic acid as the catalyst, ORGANOSILICASOL™ IPA-ST-UP elongated silica particles, water, and polymethylmethacrylate (PMMA) as the inter-particle interaction modifier. The total ash content of the solution is 4% (based on equivalent weight of SiO2 produced). The ratio of silane-based binder to silica particles (TEOS:IPA-ST-UP particles) is 50:50 ash content contribution. TEOS and silica particles are mixed with water (2 times the molar TEOS amount), acetic acid (5 times the molar TEOS amount), n-propanol, and PMMA (between 0.001 wt. % and 1 wt. % of the sol-formulation). The solution is stirred for 24 hours at room temperature.

example # 2

Example #2

[0067]A sol-formulation is prepared using Tetraethylorthosilicate (TEOS) as the silane-based binder, n-propanol as the solvent, acetic acid as the catalyst, ORGANOSILICASOL™ IPA-ST-UP elongated silica particles, water, and dextrin as the inter-particle interaction modifier. The total ash content of the solution is 4% (based on equivalent weight of SiO2 produced). The ratio of silane-based binder to silica particles (TEOS:IPA-ST-UP particles) is 50:50 ash content contribution. TEOS and silica particles are mixed with water (2 times the molar TEOS amount), acetic acid (5 times the molar TEOS amount), n-propanol, and dextrin (between 0.001 wt. % and 1 wt. %). The solution is mixed at room temperature and stirred for 24 hours at 60 degrees Celsius.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com