Condenser with capillary cooling device

a cooling device and condenser technology, applied in lighting and heating apparatus, heating types, applications, etc., can solve the problems of low heat exchange efficiency, low thermal conductivity of air, and low heat sensibleness of conventional air-cooling condensers, so as to increase the thermal efficiency of the condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

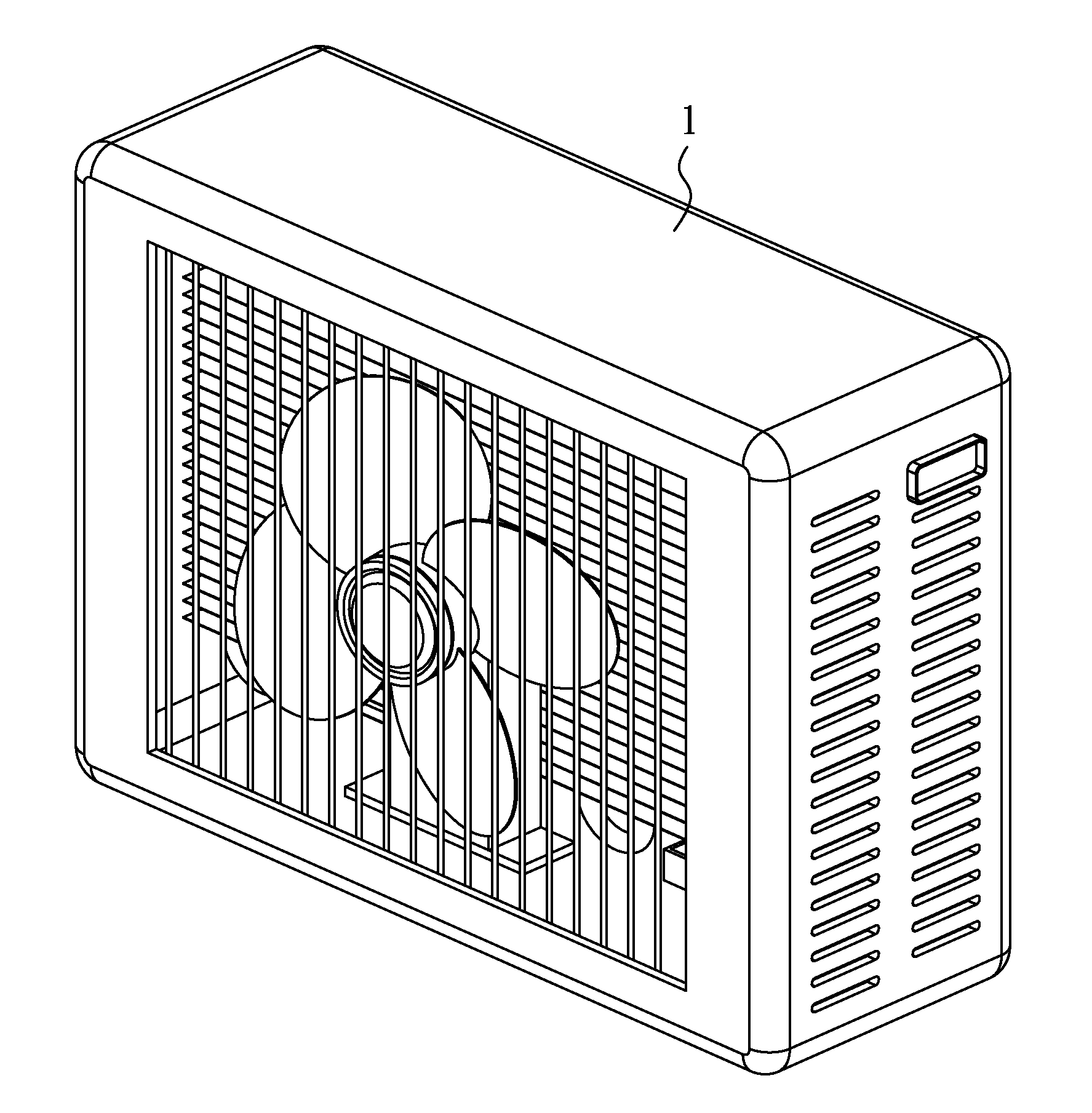

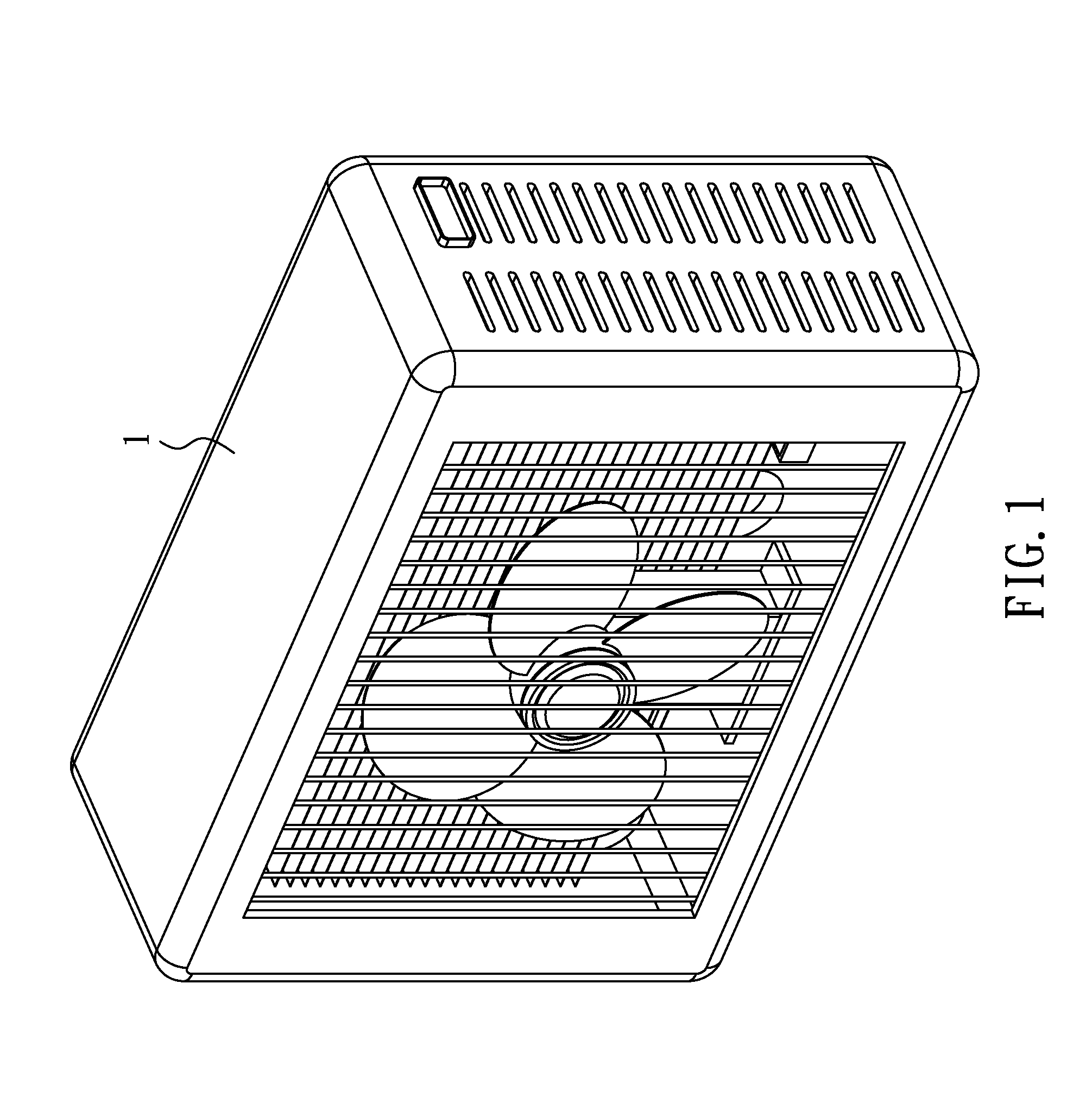

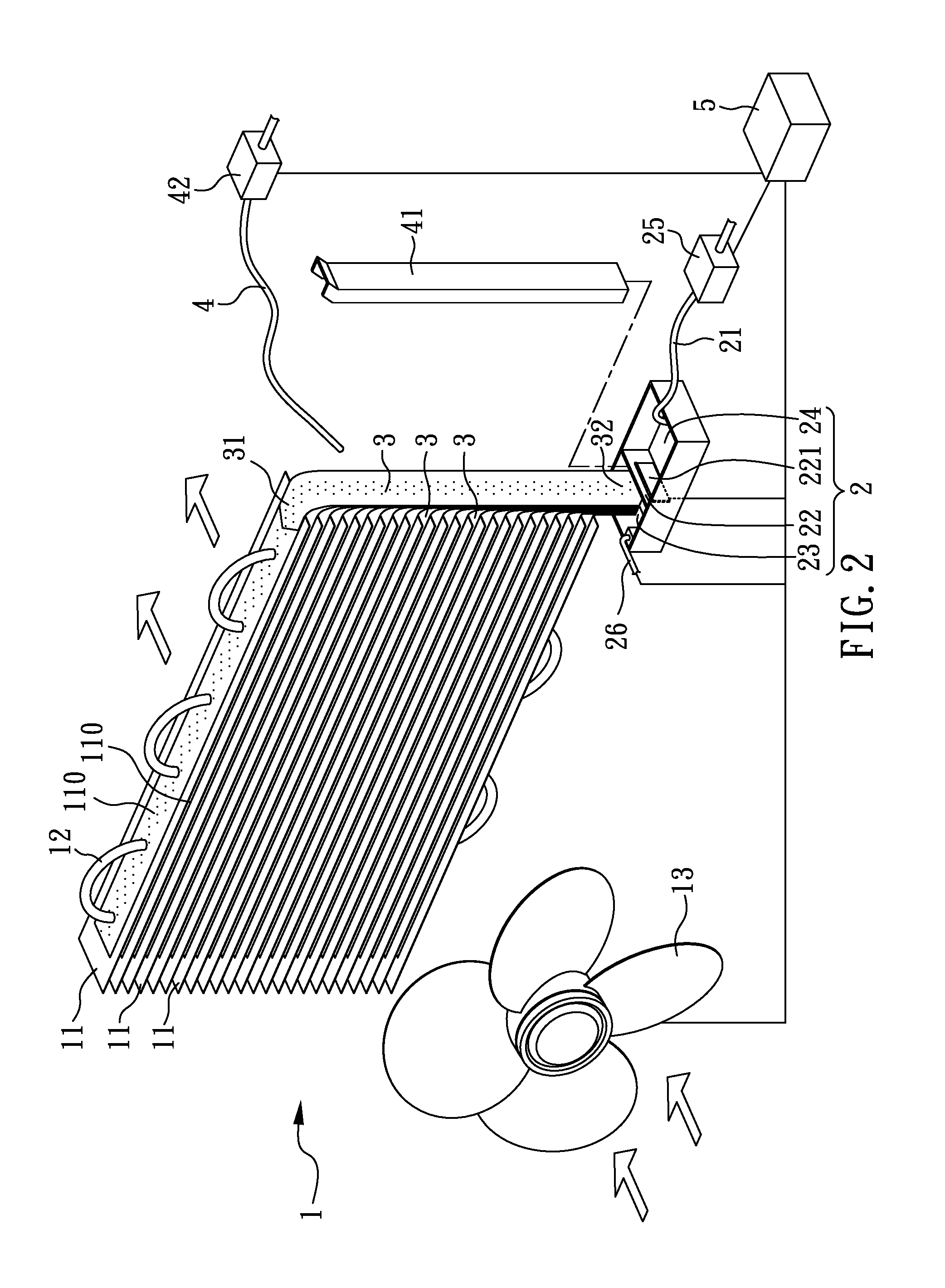

[0018]Referring to FIG. 1, a perspective view illustrating a condenser with a capillary cooling device according to a first embodiment of the present invention; and to FIG. 2, an exploded view illustrating an internal structure of a condenser according to the first embodiment of the present invention, a condenser 1 comprises a plurality of fins 11, a refrigerant coil tube 12, a water reservoir 2, a plurality of capillary water absorption layers 3, a pre-wet water pipe 4, a fan 13, and a controller 5. The controller 5 is arranged inside a housing of the condenser 1, and is electrically connected with a solenoid 42, a valve 221, a check valve 25, a water-level sensor 26, and a fan 13.

[0019]As shown in FIG. 2, the refrigerant coil tube 12 is inserted into and among the plurality of fins 11 horizontally arrayed. And at least one side of each fin of the plurality of fins 11 is provided with a wick structure 110. In the present embodiment, each capillary water absorption layer of the plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com