Method and device for operating an internal combustion engine in the event of a fault in a crankshaft sensor

a crankshaft sensor and internal combustion engine technology, applied in the direction of non-mechanical valves, electrical control, valve drives, etc., can solve the problems of deteriorating the camshaft is no longer available, etc., to improve the exhaust gas performance of the internal combustion engine, improve the internal combustion engine's exhaust gas performance, and reduce the control effort required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Identical features are indicated by the same reference symbols.

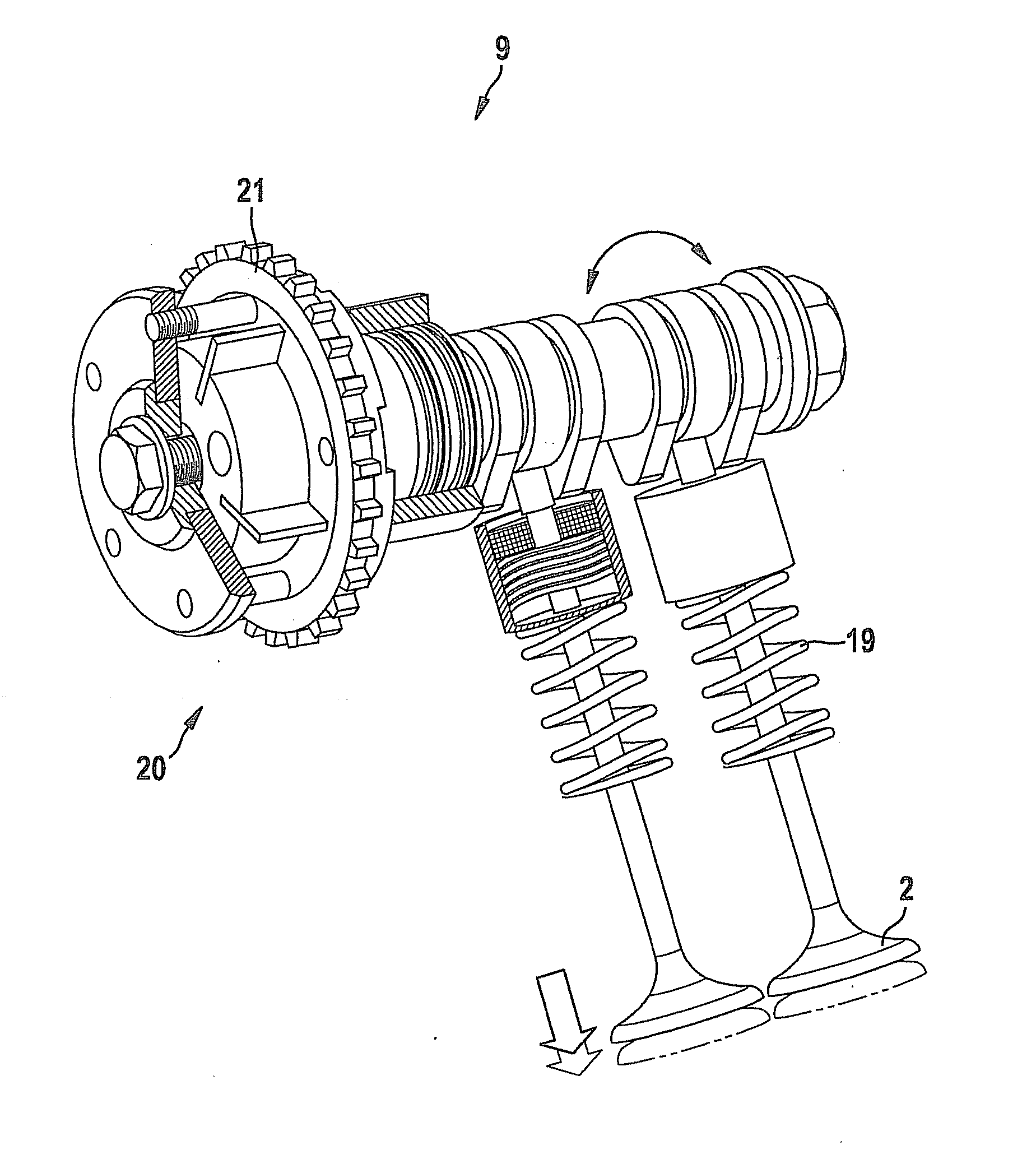

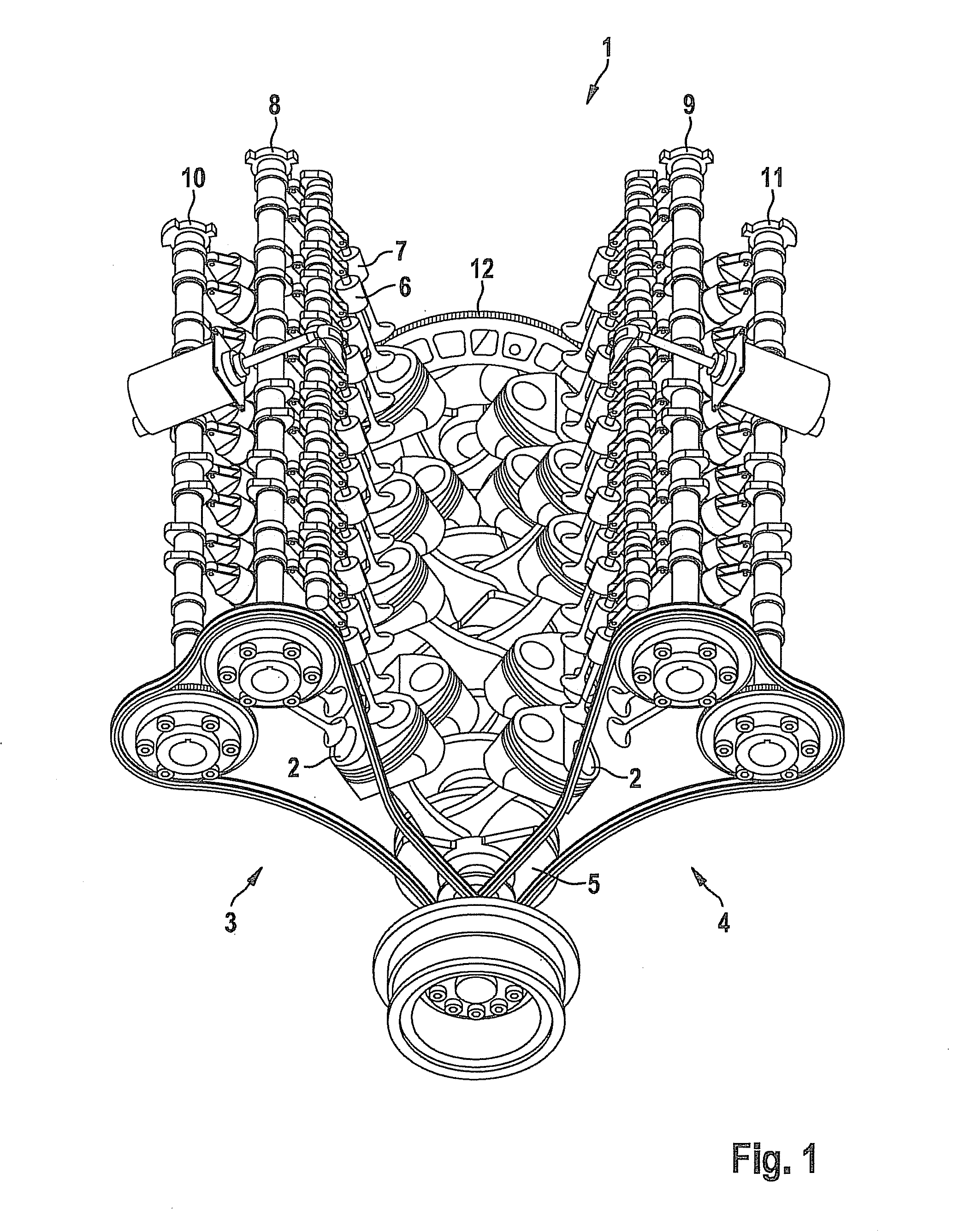

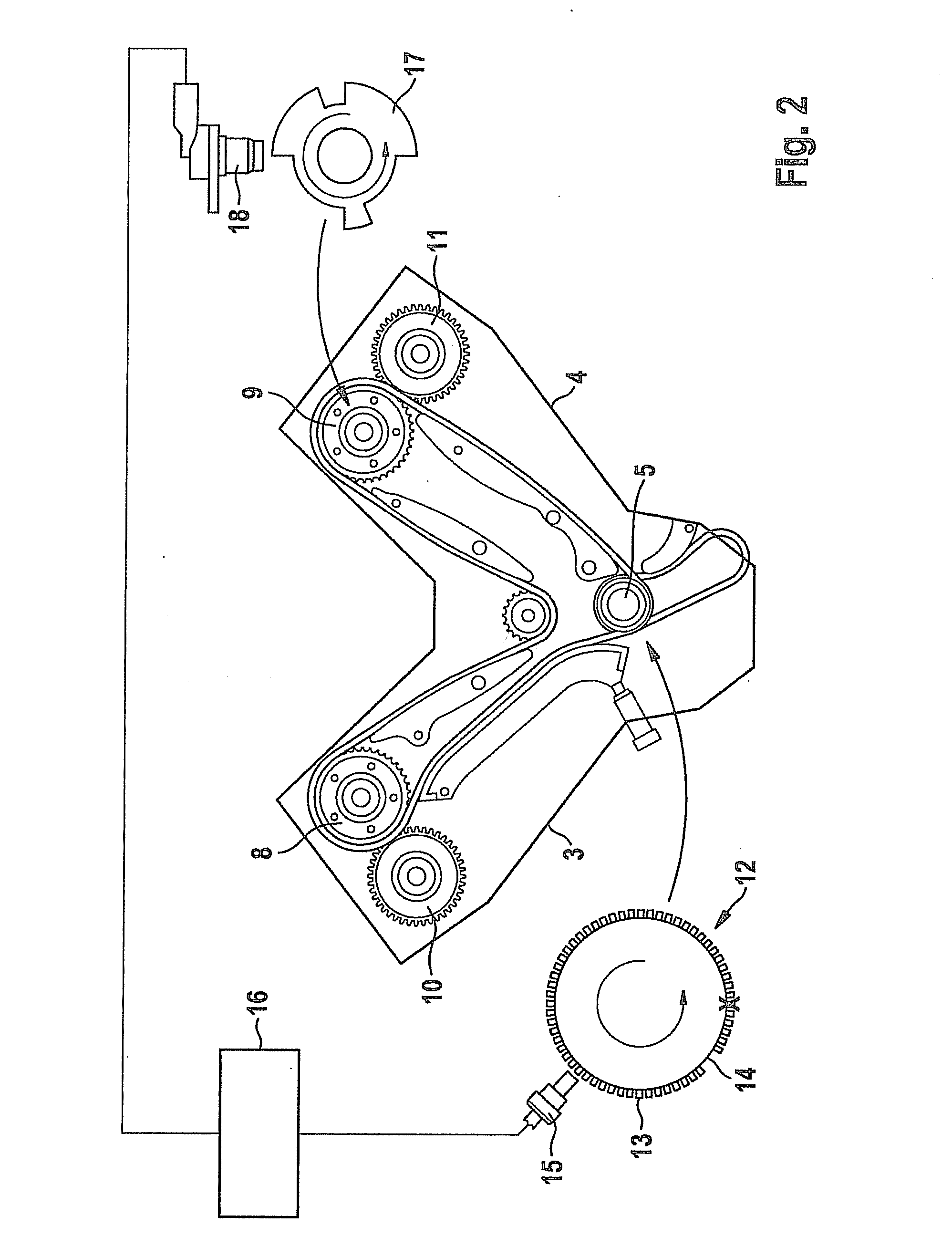

[0021]FIG. 1 shows a basic representation of an internal combustion engine 1 in the shape of a V. In this instance, cylinders 2 of internal combustion engine 1 are arranged in a v-shape on two planes 3, 4, a crankshaft 5 being situated at the intersection of the two planes 3, 4. Each plane 3, 4 is typically called a bank. Each cylinder 2 is equipped with one or more intake valves 6 and one exhaust valve 7. Fresh air and fuel are conveyed through intake valve 6 into the respective cylinder 2 of internal combustion engine 1, while the combustion products of cylinder 2 in the form of exhaust gas are discharged from internal combustion engine 1 via exhaust valve 7. Intake valves 6 of first plane 3 of cylinders 2 are connected to a first camshaft 8, while exhaust valves 7 of first plane 3 are operated by a second camshaft 10. Analogously, intake valves of second plane 4 of cylinders 2 connect to a third camshaft 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com