Oxy-Fuel Furnace and Method of Heating Material in an Oxy-Fuel Furnace

a technology of oxy-fuel furnace and oxy-fuel furnace, which is applied in the direction of combustion of lump and pulverulent fuel, combustion types, lighting and heating apparatuses, etc. it can solve the problems of increasing the potential for inconsistent or uneven heating, hot spots, and nox generation, and achieves uniform heating within the enclosure, increases convective heating, and increases the shape factor effect of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Provided is an exemplary oxy-fuel furnace and method of heating material in an oxy-fuel furnace. Embodiments of the present disclosure increase the convective contribution of heat transfer in an oxy-fuel heating process, decrease the cycle time for achieving certain temperatures, increase efficiency, or combinations thereof.

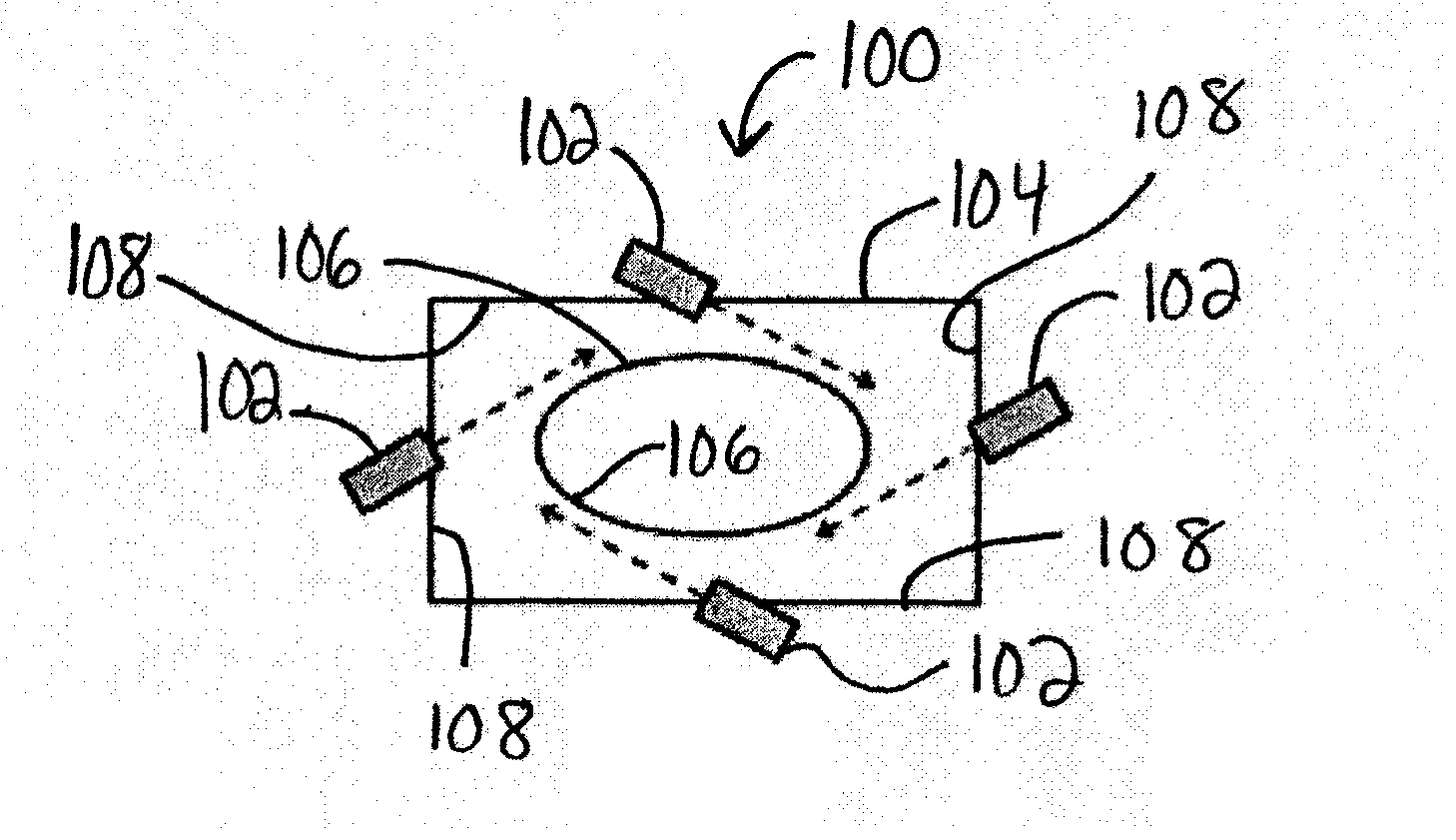

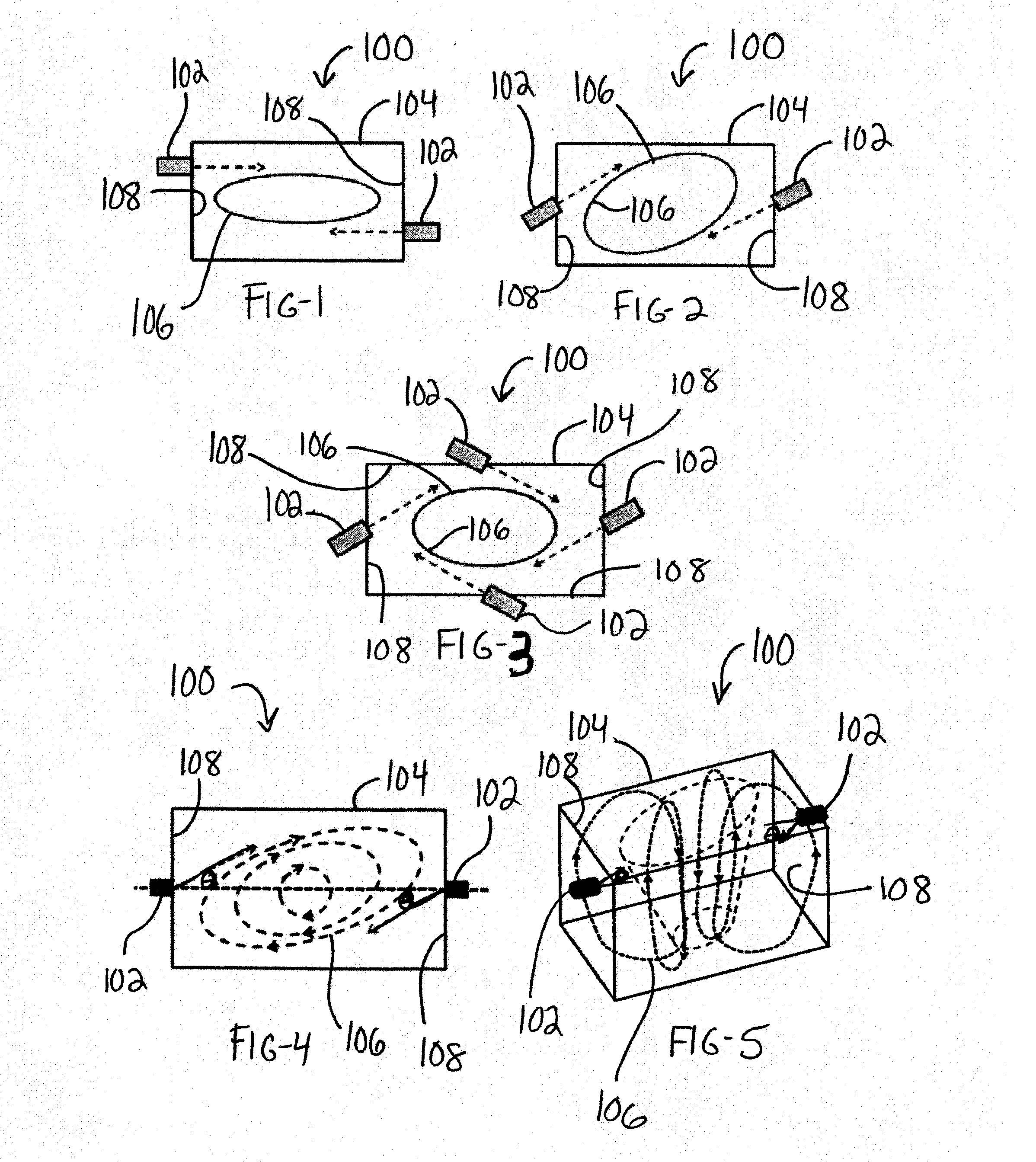

[0020]Referring to FIGS. 1 through 5, according to an embodiment, an oxy-fuel furnace 100 includes at least two high-momentum oxy-fuel burners 102 and an enclosure 104 generally defining a combustion zone within the oxy-fuel furnace 100. The enclosure 104 is any suitable geometry and is defined by a furnace wall boundary 108. For example, in one embodiment, the enclosure 104 is a cuboid or generally cuboid geometry. In another embodiment, the enclosure 104 is a cylindrical or generally cylindrical geometry. The enclosure includes a central region, for example, defined by the burner axis of each of the burners 102, the burner axis being a line extending from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com