Preparation of wear resistant rubber composite material

A composite material and wear-resistant rubber technology, which is applied in the preparation field of graphite/rubber composite materials, can solve the problems of difficult suspension, no ion exchange performance, poor hydrophilicity, etc., and achieve simplified preparation process and excellent mechanical properties , the effect of small aggregate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

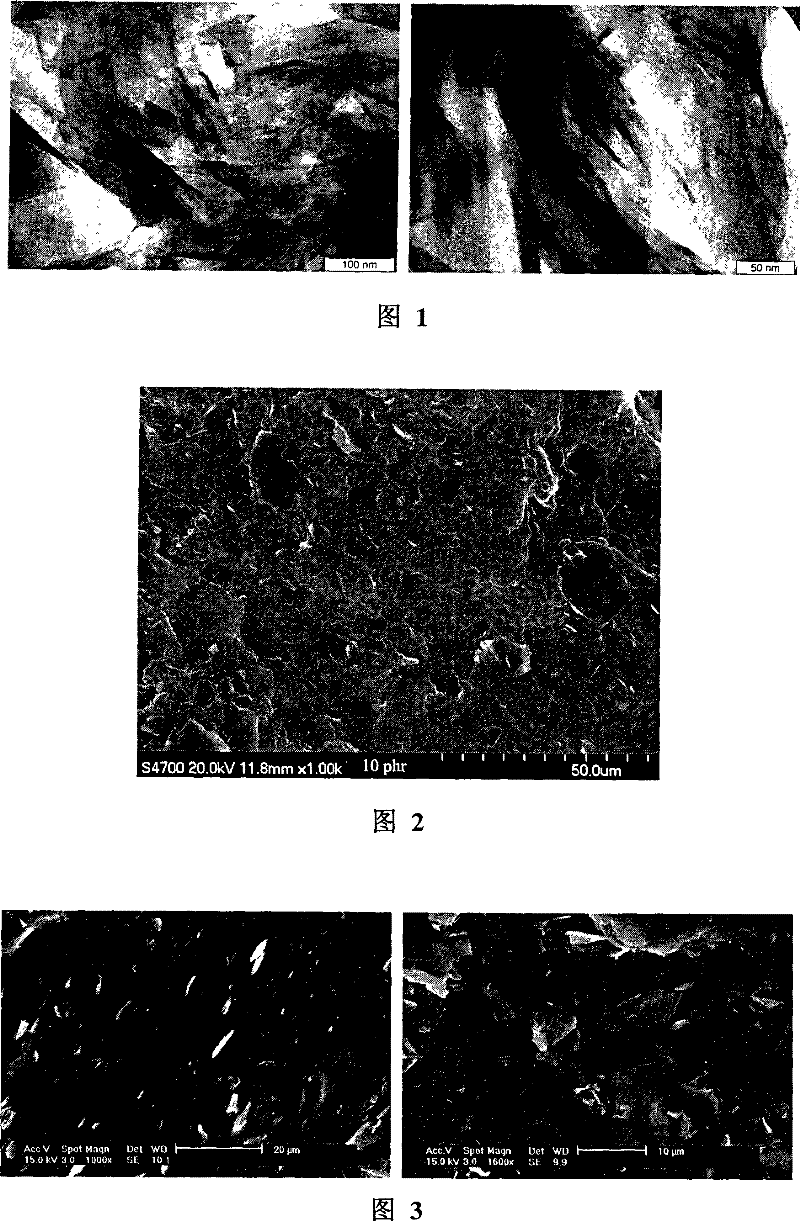

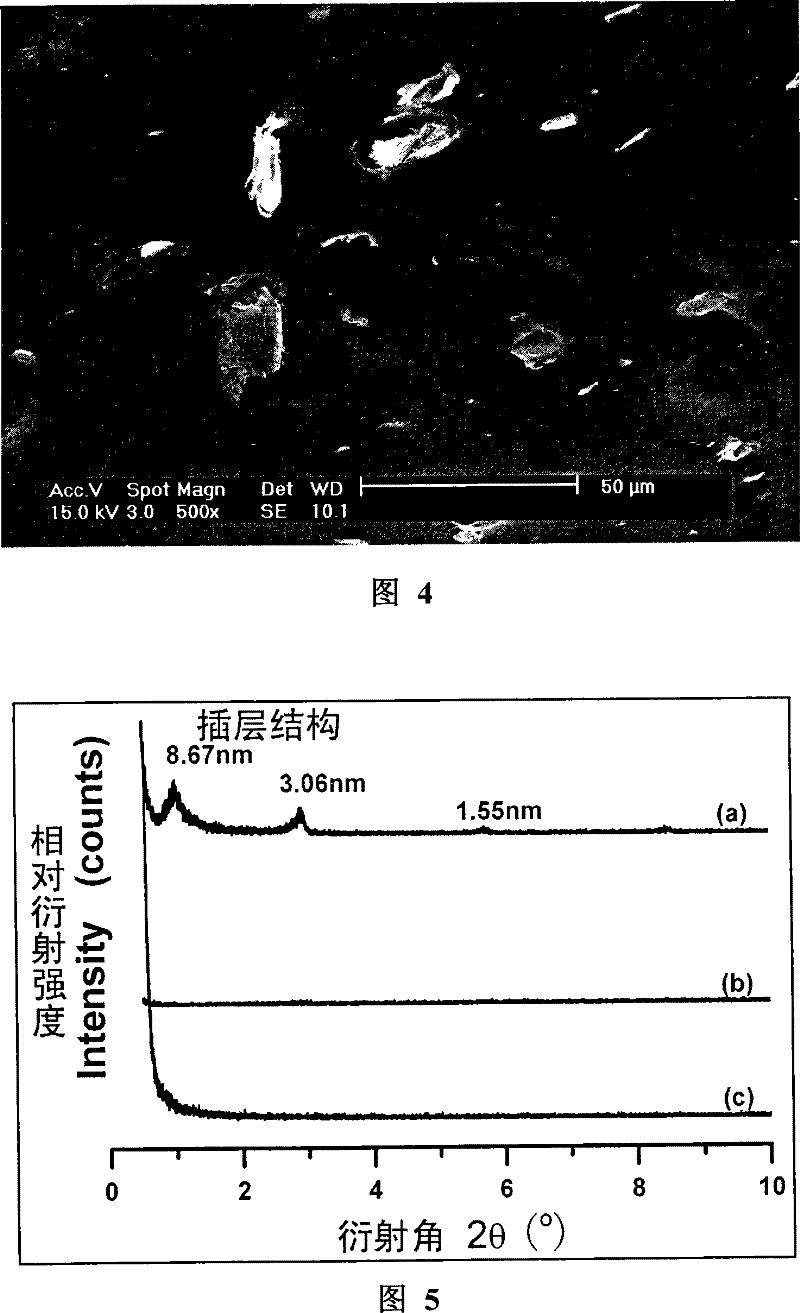

[0029] Heat and expand 0.5 g of graphite intercalation compound (expandable graphite) in a microwave oven with a power of 750 W for 30 seconds to obtain expanded graphite. Repeat this expansion process until 10g of expanded graphite is collected. At this time, the sheets of expanded graphite are relatively large and overlap each other, and the entire graphite particle is in the shape of a worm. Soak the expanded graphite in 15L of deionized water containing 50g of surfactant sodium dodecylsulfonate, and stir for 24 hours. At this time, most of the graphite will be soaked by water and sink to the bottom of the beaker. The floating graphite in the non-wetted part was taken out, washed and dried at 120° C. to a constant weight of 2 g. Then ultrasonically treat the mixed solution for 2.5 hours, the infiltrated expanded graphite particles are crushed and refined and the graphite flakes are dispersed to obtain a water suspension system of nano-graphite flakes, and the amount of grap...

Embodiment 2

[0032] The operating steps are the same as in Example 1. The expanded graphite aqueous suspension after the ultrasonic treatment is mixed with 178g of carboxylated nitrile rubber latex with a solid content of 45%, which contains 80g of carboxylated nitrile rubber. Then add 1wt% CaCl 2 The aqueous solution was flocculated, washed, and dried in a blast oven at 50°C for 24 hours.

[0033] On the double-roller mill, 110 parts of the above-mentioned graphite / carboxylated nitrile rubber nanocomposites (containing 100 parts of carboxylated nitrile butadiene rubber, 10 parts of graphite) are plasticized, and then add various auxiliary agents successively: 4 parts of DCP, Knead to obtain rubber compound. Then vulcanize at 160°C according to the positive curing time to obtain vulcanized rubber. Tested according to national standards, the mechanical properties of composite materials are shown in Table 1, and the transmission electron microscope photos of composite materials are shown ...

Embodiment 3

[0035] The operating steps are the same as in Example 1. The expanded graphite aqueous suspension after ultrasonic treatment was mixed with 400 g of acrylate rubber latex with a solid content of 20%, which contained 80 g of acrylate rubber. Then add 1wt% CaCl 2 The aqueous solution was flocculated, washed, and dried in a blast oven at 50°C for 24 hours.

[0036] On a double-roller mill, masticate 110 parts of the above-mentioned graphite / carboxylated nitrile rubber nanocomposite (containing 100 parts of acrylate rubber and 10 parts of graphite), and then add various auxiliary agents in turn: 1 part of vulcanizing agent TCY , 1.5 parts of accelerator BZ, 0.2 parts of anti-scorch agent CTP, 1.5 parts of processing aid polyethylene glycol 4000, mixed to obtain rubber compound. Then vulcanize at 160°C according to the positive curing time to obtain vulcanized rubber. Tested according to national standards, the mechanical properties of composite materials are shown in Table 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com