Use of adsorption or absorption technologies for thermal-electric power plant cooling

a technology of thermal-electric power plant, which is applied in the field of system and method of using adsorption or absorption chiller for thermal-electric power plant cooling, can solve the problems of large air-cooled condensers and commercial adsorption or absorption chillers that have not been popularly used, and achieve the effect of reducing water use and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

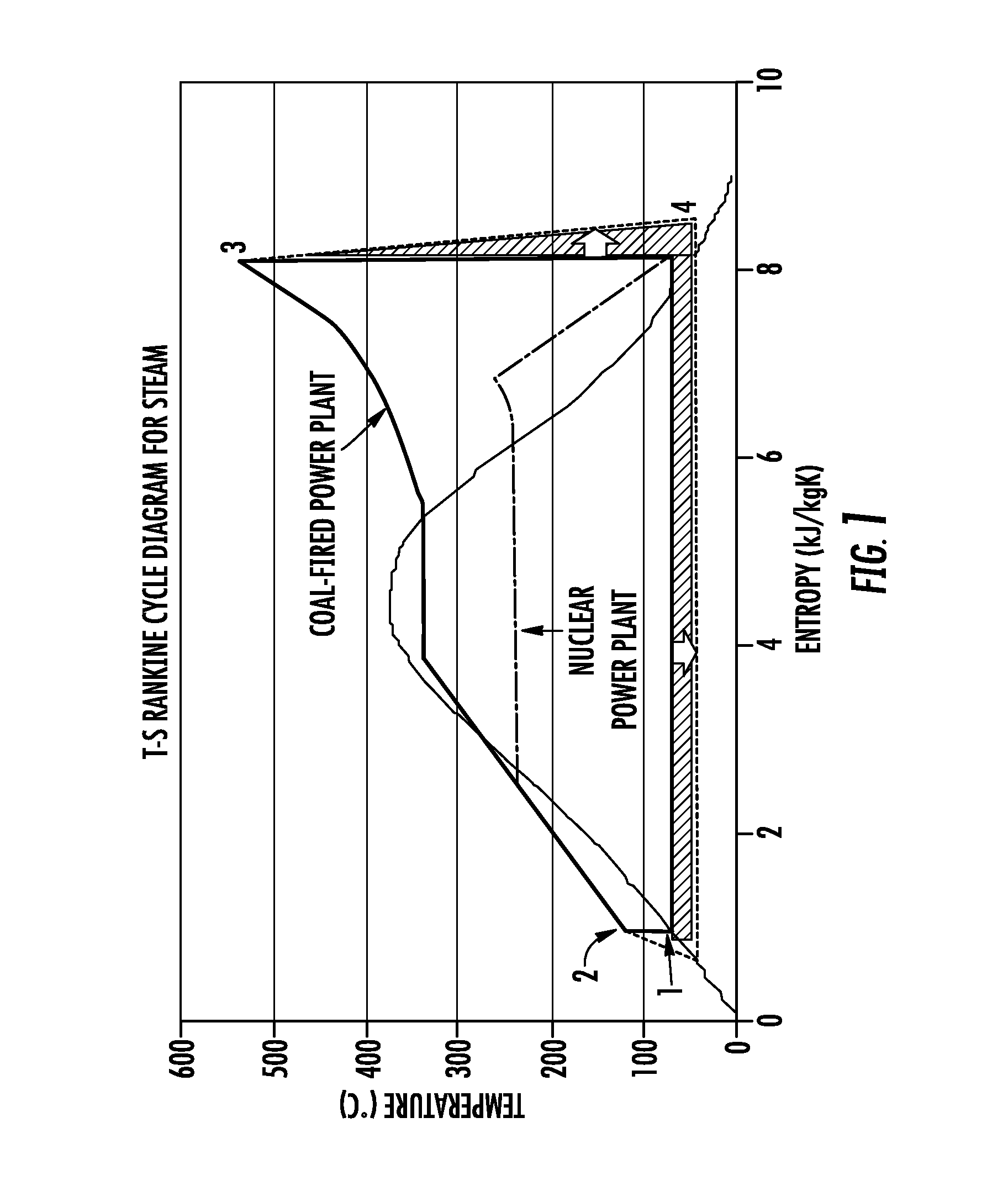

[0022]As shown in FIG. 1, during a typical steam power plant Rankin cycle, the condensed steam is pressurized by a pump from 1 to 2, the water is then boiled to become steam again from 2 to 3, and the steam expands through the turbine to generate work from 3 to 4. The higher the steam turbine inlet steam temperature or the lower the steam turbine exhaust temperature or the condensing temperature, the more the work generated and thus the higher the power plant thermal cycle efficiency.

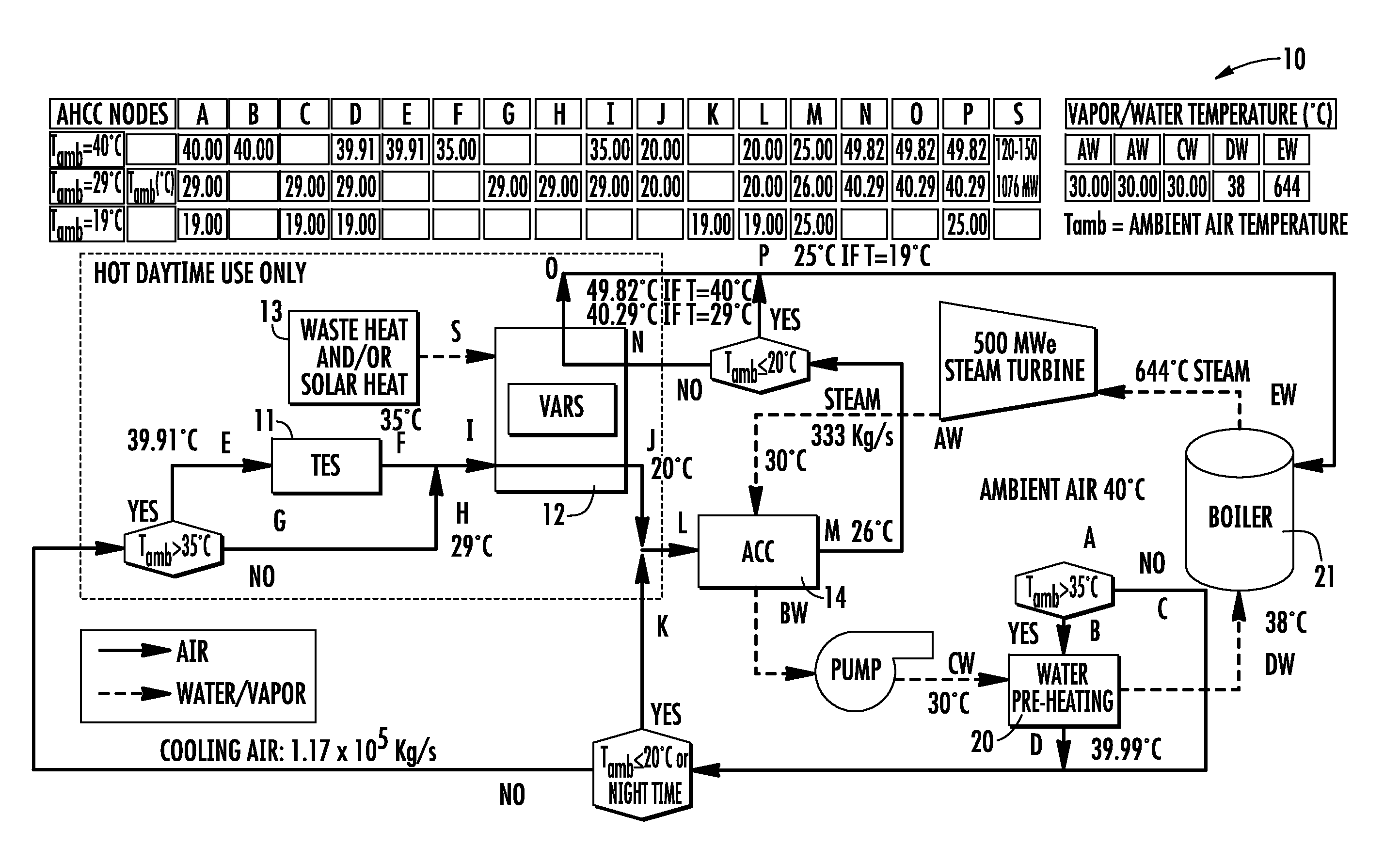

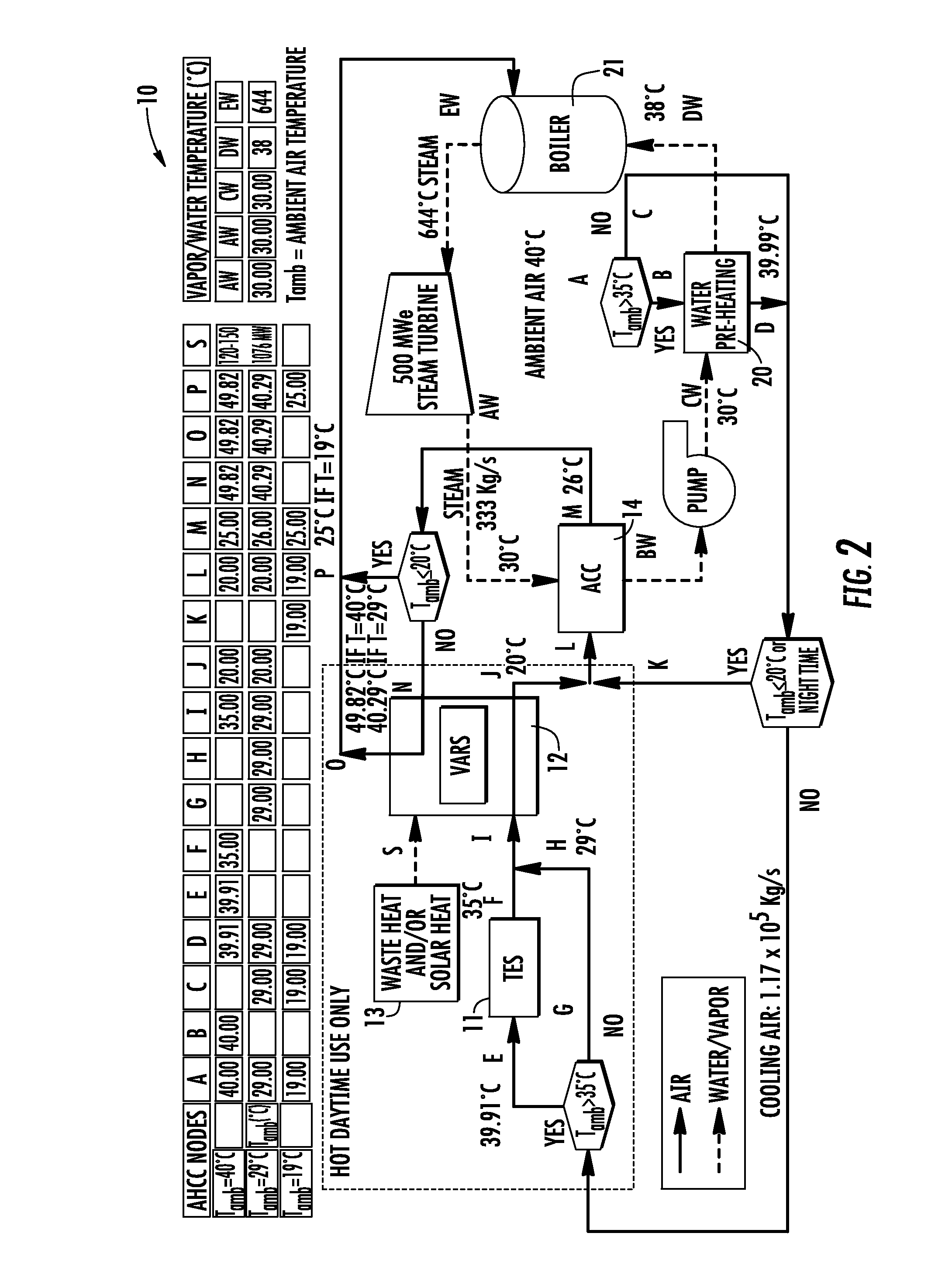

[0023]The present invention, shown generally in FIG. 2 at reference numeral 10, is an Advanced Hybrid Condenser Cooling system (AHCC) adapted for use in a steam power plant. The AHCC system 10 is a high efficiency dry cooling system designed to replace current air-cooled condenser (ACC) or wet cooling systems and eliminate the disadvantages associated with those systems by using nature to control air temperature to enhance ACC and to achieve zero water cooling for steam condensation. It should be apprec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com