Linear Actuator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

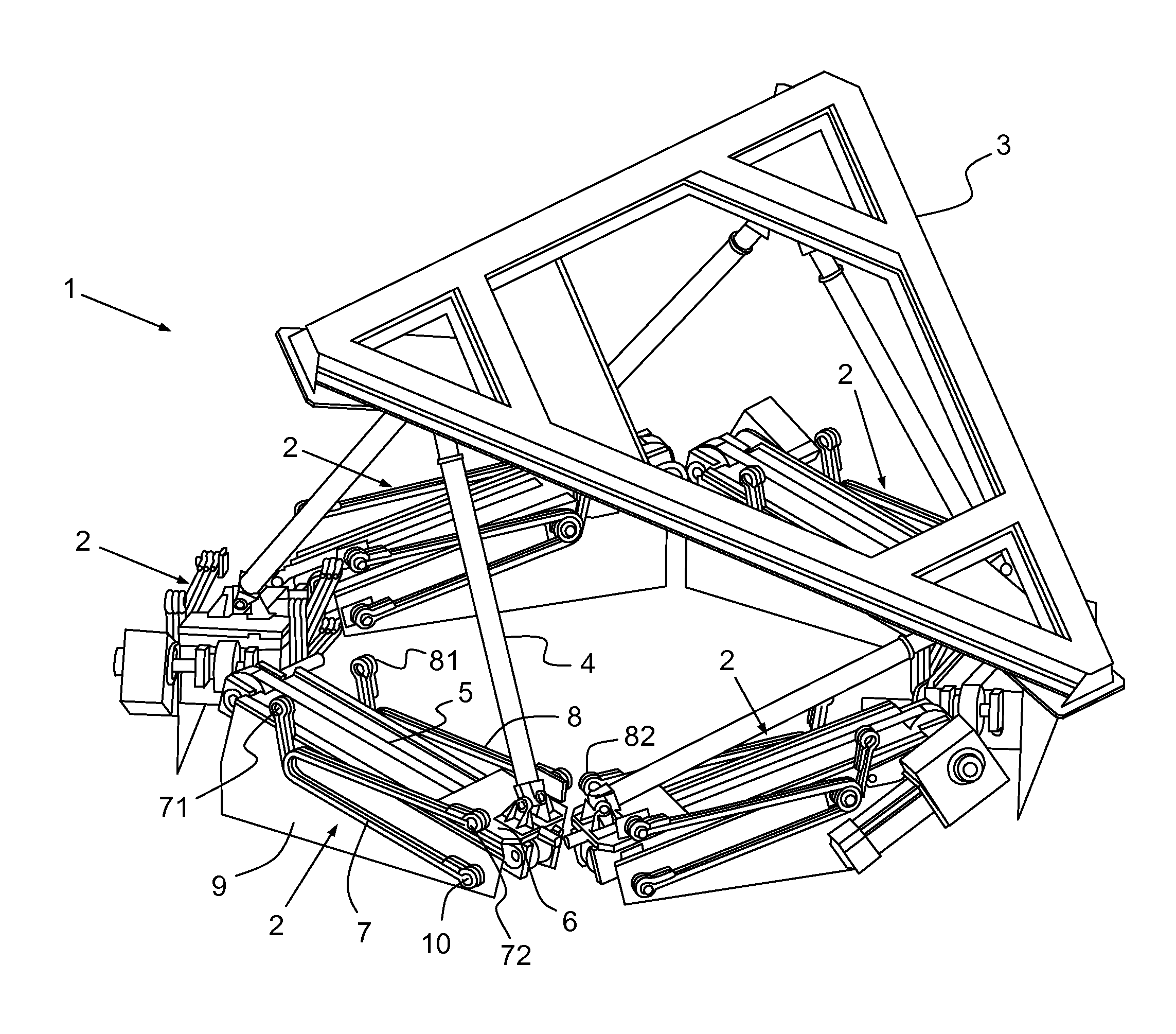

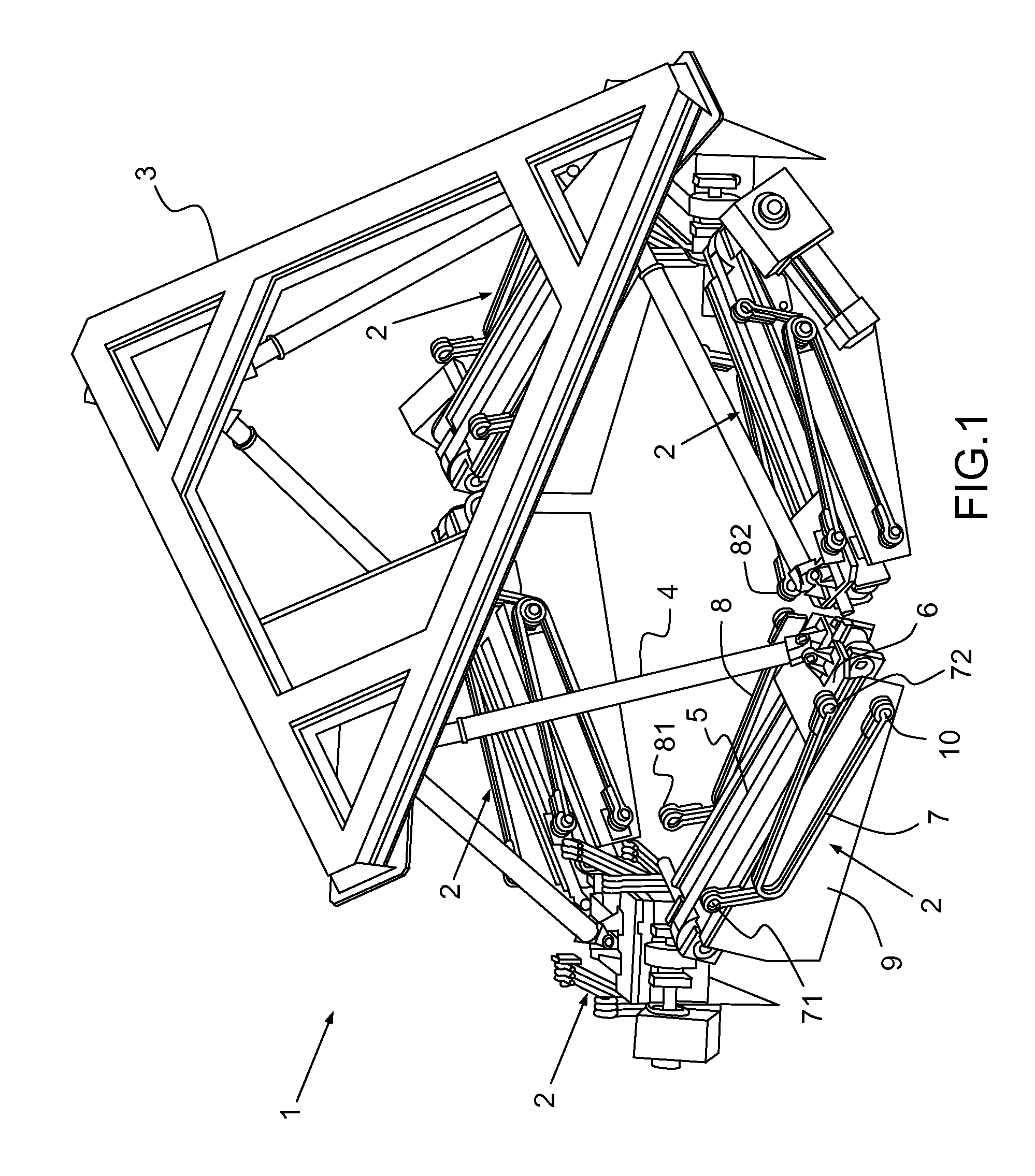

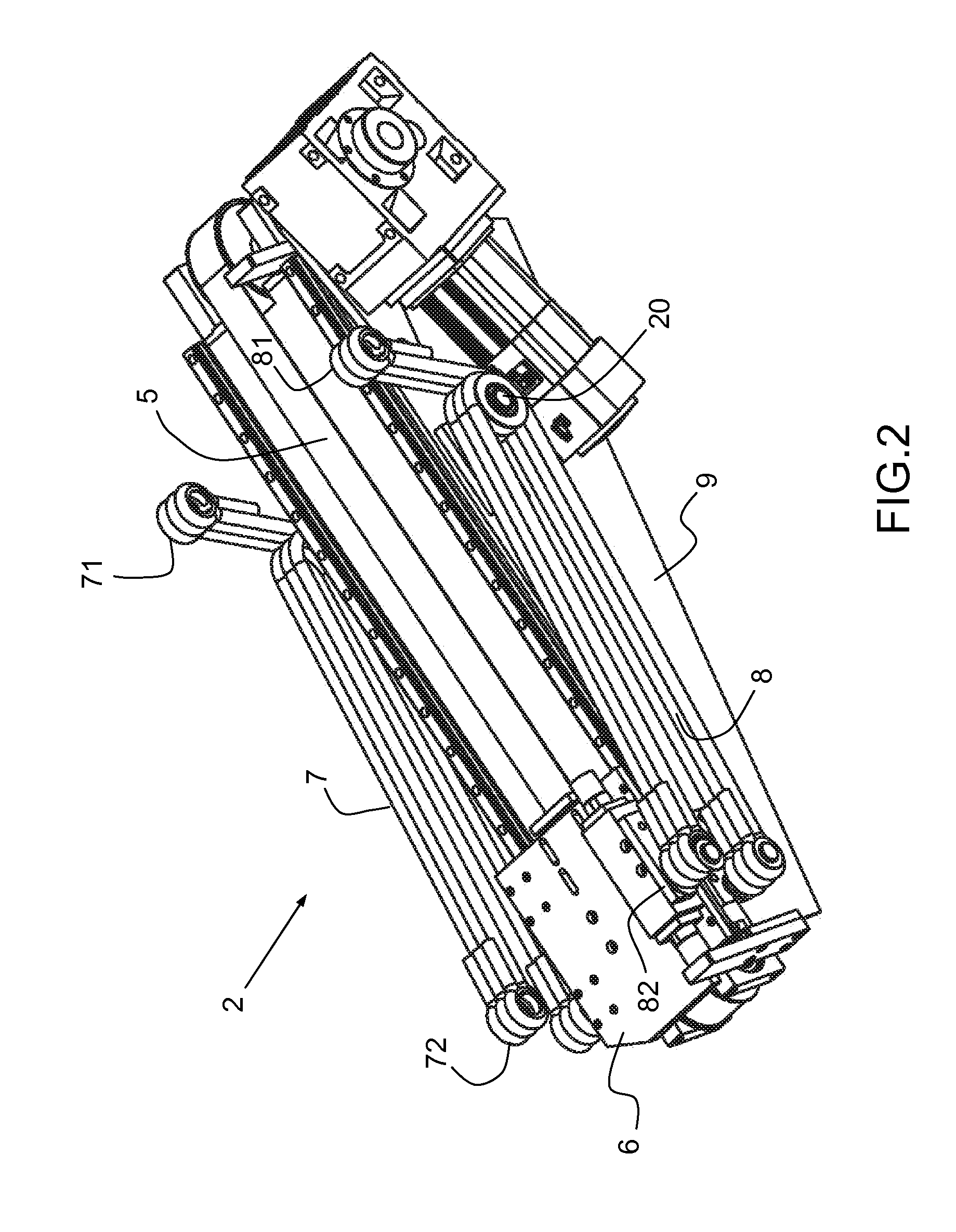

[0035]FIG. 1 represents a hexapod positioner 1 comprising at least one actuator 2 according to the invention. The hexapod positioner 1 can set a mobile platform 3 in motion. The hexapod positioner 1 can be produced according to the Stewart platform concept allowing for movement of the mobile platform 3 according to six degrees of freedom. Three degrees of freedom in translation, three degrees of freedom in rotation according to pitch, roll and yaw angles, otherwise called Euler angles. The Stewart platforms are notably used to produce simulators after a design by K. Cappel. The Stewart platforms form part of the family of parallel robots.

[0036]The hexapod positioner 1 notably comprises six actuators. The load of the platform 3 is distributed over the six actuators of the hexapod positioner 1. For example, the six actuators may be actuators 2 according to the invention. In another exemplary embodiment, a hexapod positioner may comprise at least one actuator 2 according to the inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com