Polyphenylether resin alloy material used for processing spinning cans and preparation method

A polyphenylene ether resin and alloy material technology, applied in the field of polymer alloys, can solve the problems of delamination and peeling of yarn tubes, easy stickiness of small molecules on the surface, and staining of yarn tubes, so as to achieve high production efficiency and avoid delamination and peeling , not sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The embodiment of the present invention also provides a method for preparing a polyphenylene ether resin alloy material for processing a spinning bobbin, comprising the following steps:

[0045] S01. Weighing the formula components: weighing each component according to the above-mentioned polyphenylene ether resin alloy material formula;

[0046] S02. Prepare a mixed material: divide the polyphenylene ether resin weighed in step S01 into two parts, and mix one part of the polyphenylene ether resin with the rest of the components except the polystyrene resin to form a mixed material;

[0047] S03. Melt extrusion of materials: after adding another portion of polyphenylene ether resin, polystyrene resin and the mixed material from different weight loss feeder ports, melt extrusion is carried out.

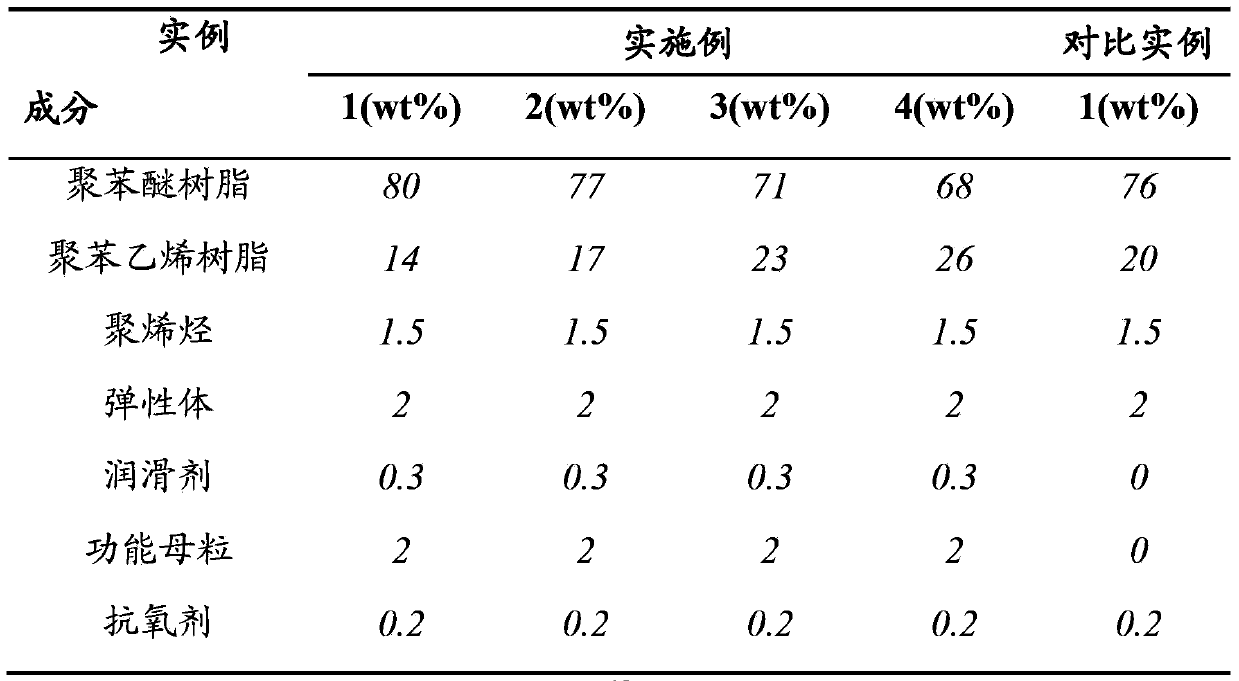

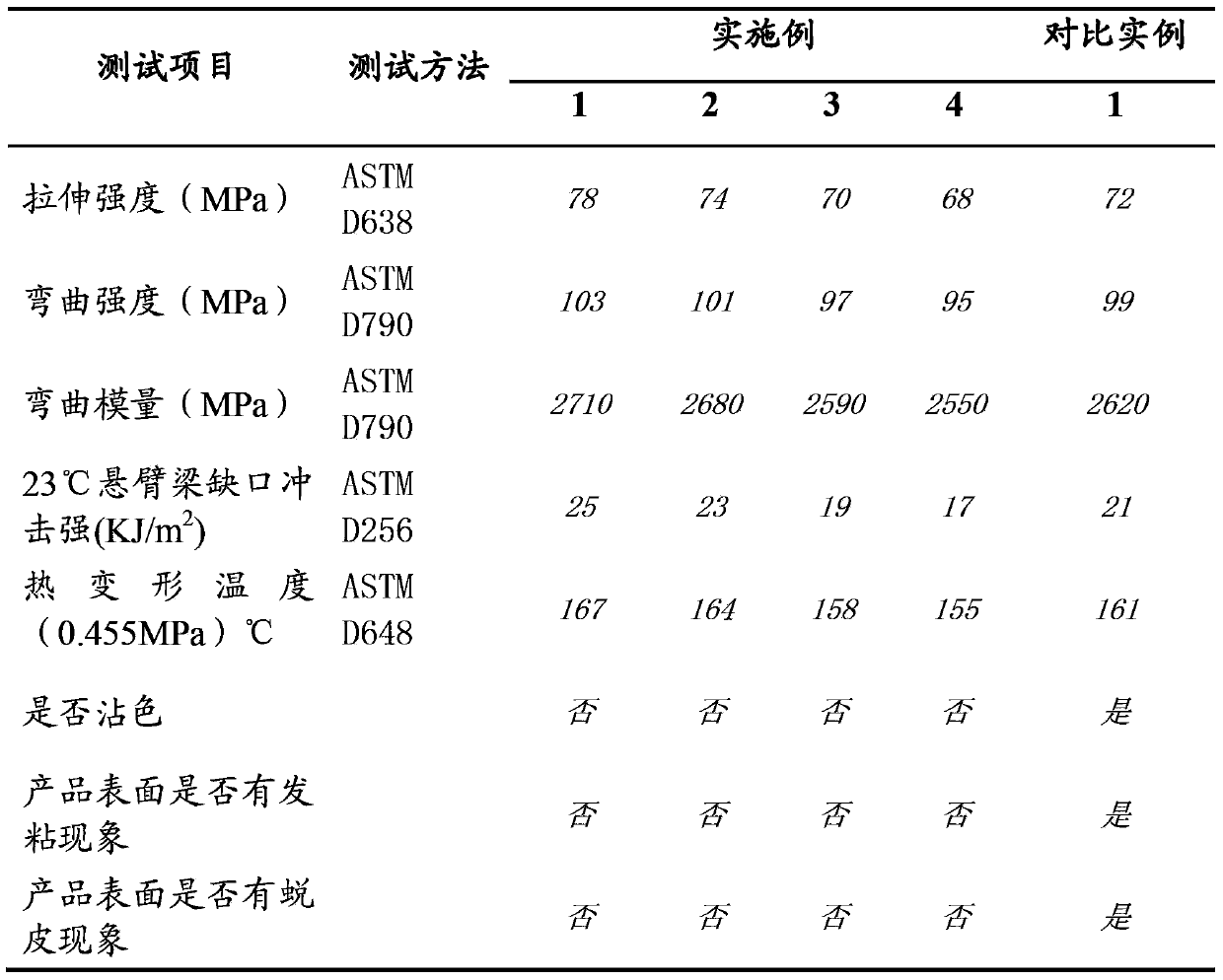

[0048] Specifically, in the above step S01, the formulation of the polyphenylene ether resin alloy material and the preferred content and type of each component in the formulati...

Embodiment 1

[0057] Add 50 parts of polyphenylene ether resin from the first weight loss feeding port, 14 parts of polystyrene resin from the second weight loss feeding port, 30 parts of polyphenylene ether resin, 1.5 parts of polyolefin, 2 parts of elastomer, 0.3 parts Lubricant, 2 parts of functional masterbatch, and 0.2 parts of antioxidant are added from the third weight loss feeder after high mixing, and then plasticized, melted, extruded, drawn, cooled and pelletized through a twin-screw extruder. The pellets were dried in a blower drying oven at 120°C for 2-4 hours, and then injection molded to prepare test samples and products.

Embodiment 2

[0059] Add 50 parts of polyphenylene ether resin from the first weight loss feeding port, 17 parts of polystyrene resin from the second weight loss feeding port, 27 parts of polyphenylene ether resin, 1.5 parts of polyolefin, 2 parts of elastomer, 0.3 parts Lubricant, 2 parts of functional masterbatch, and 0.2 parts of antioxidant are added from the third weight loss feeder after high mixing, and then plasticized, melted, extruded, drawn, cooled and pelletized through a twin-screw extruder. The pellets were dried in a blower drying oven at 120°C for 2-4 hours, and then injection molded to prepare test samples and products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com