Integrated hydrotreating and steam pyrolysis process for direct processing of a crude oil

a technology of hydrotreating and steam pyrolysis, which is applied in the direction of hydrocarbon oil treatment products, liquid degasification, separation processes, etc., can solve the problems of inability to meet the needs of crude oil processing, etc., to achieve the effect of reducing the correlation index of the bureau of mines, reducing the content of contaminants, and increasing paraffinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

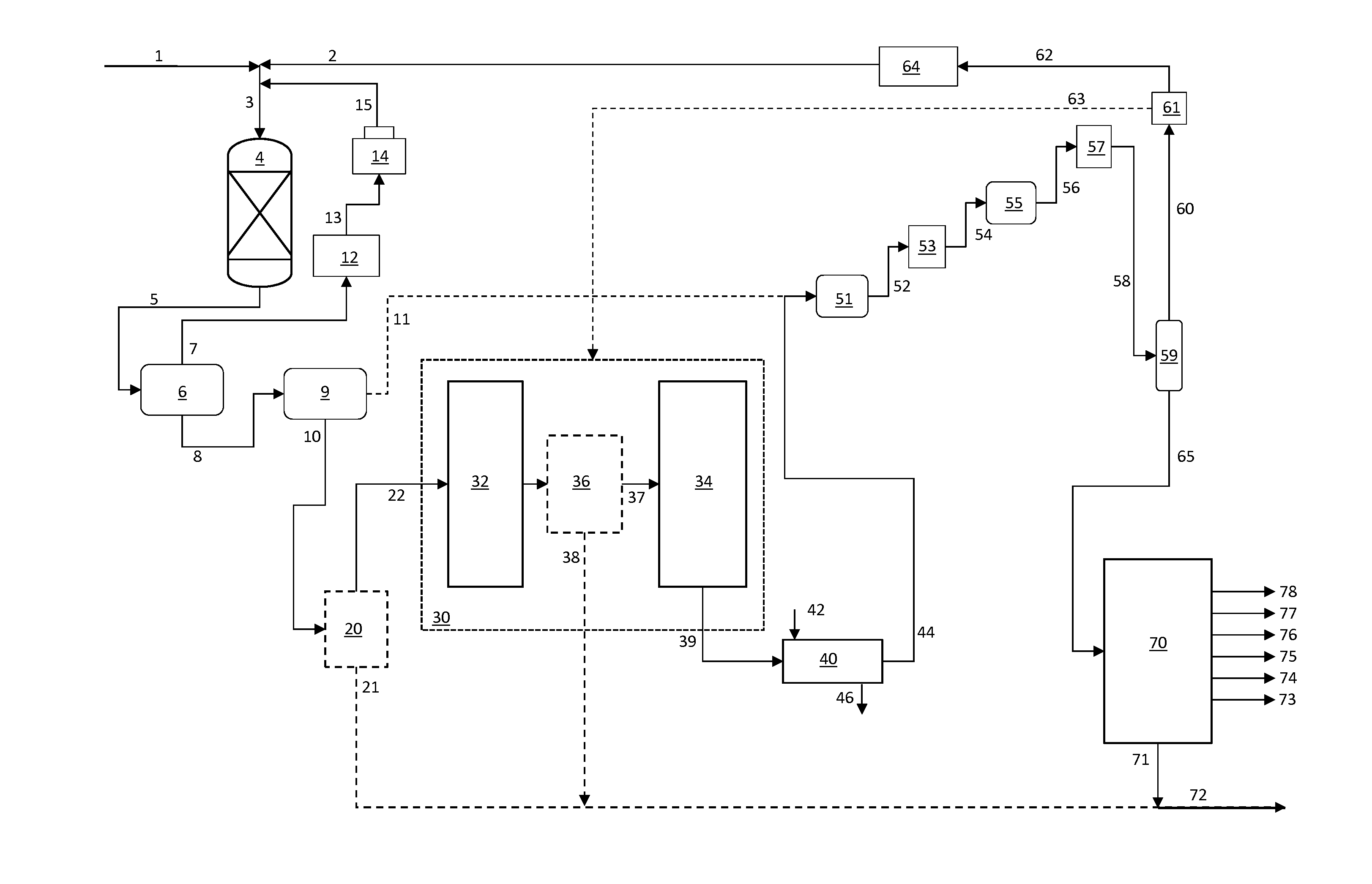

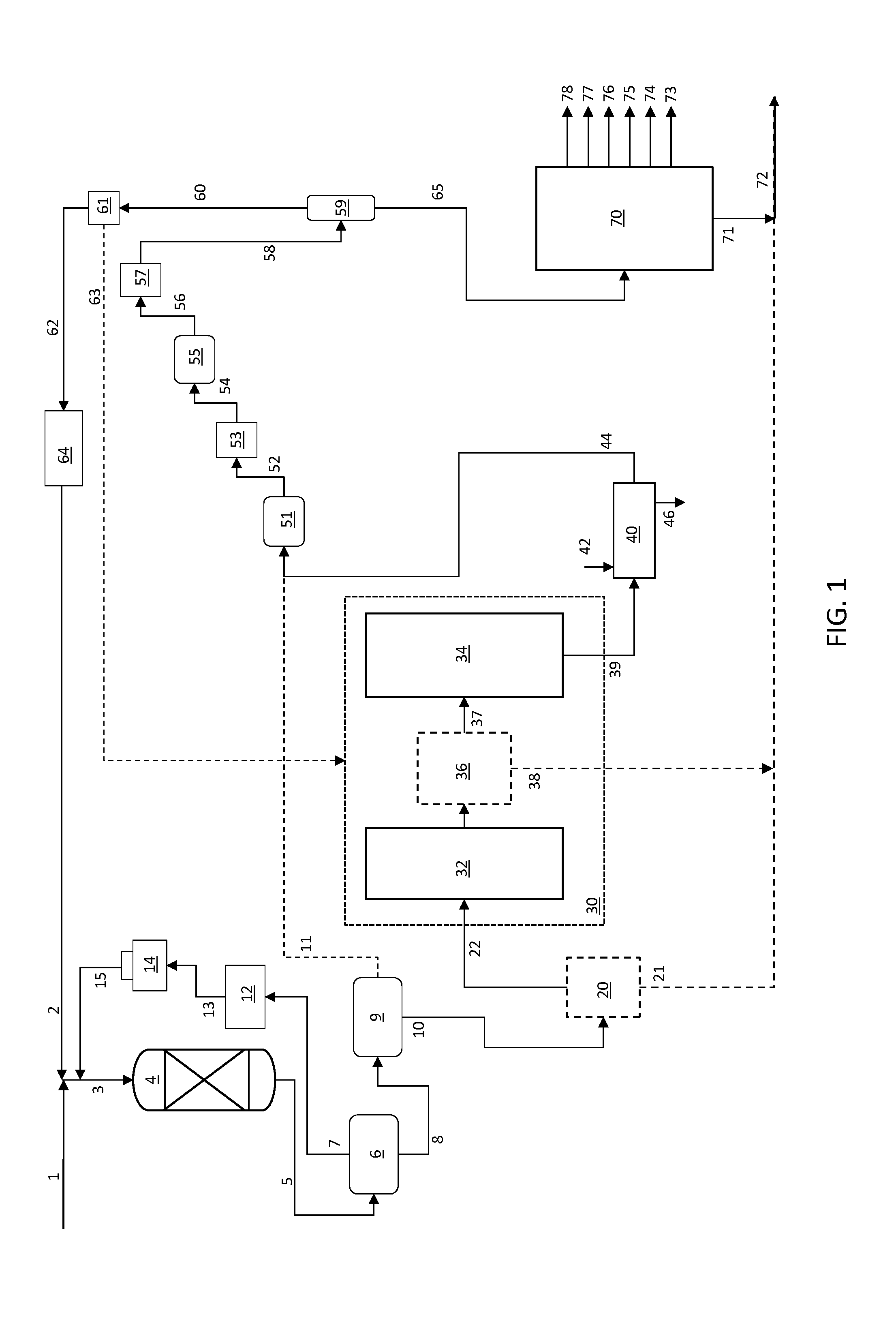

[0022]A process flow diagram including an integrated hydroprocessing and steam pyrolysis process and system is shown in FIG. 1. The integrated system generally includes a selective catalytic hydroprocessing zone, an optional separation zone 20, a steam pyrolysis zone 30 and a product separation zone.

[0023]Selective hydroprocessing zone includes a hydroprocessing reaction zone 4 having an inlet for receiving a mixture of crude oil feed 1 and hydrogen 2 recycled from the steam pyrolysis product stream, and make-up hydrogen as necessary. Hydroprocessing reaction zone 4 further includes an outlet for discharging a hydroprocessed effluent 5.

[0024]Reactor effluents 5 from the hydroprocessing reactor(s) are cooled in a heat exchanger (not shown) and sent to a high pressure separator 6. The separator tops 7 are cleaned in an amine unit 12 and a resulting hydrogen rich gas stream 13 is passed to a recycling compressor 14 to be used as a recycle gas 15 in the hydroprocessing reactor. A bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com