Closure for plastic packaging containers

a plastic packaging container and lid technology, applied in the field of lids for plastic packs, can solve the problems of partial no way of compensating the vacuum without weakening the pack structure, and collapse of the pack wall, and achieve the effect of low cost, simple structure, and efficient assurance of the integrity of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Initially, it must be reiterated that the lid for plastic packs addressed by this invention will be described below according to preferred realizations that are not limiting, as its application may be valid for different packs and for packaging different products presenting variations in the vacuum resulting from the reduction in the product volume and its vapor pressure while cooling after filling during the fabrication process or through the consumption of O2 in the air found in the pack through oxidation reactions during the useful life of the product.

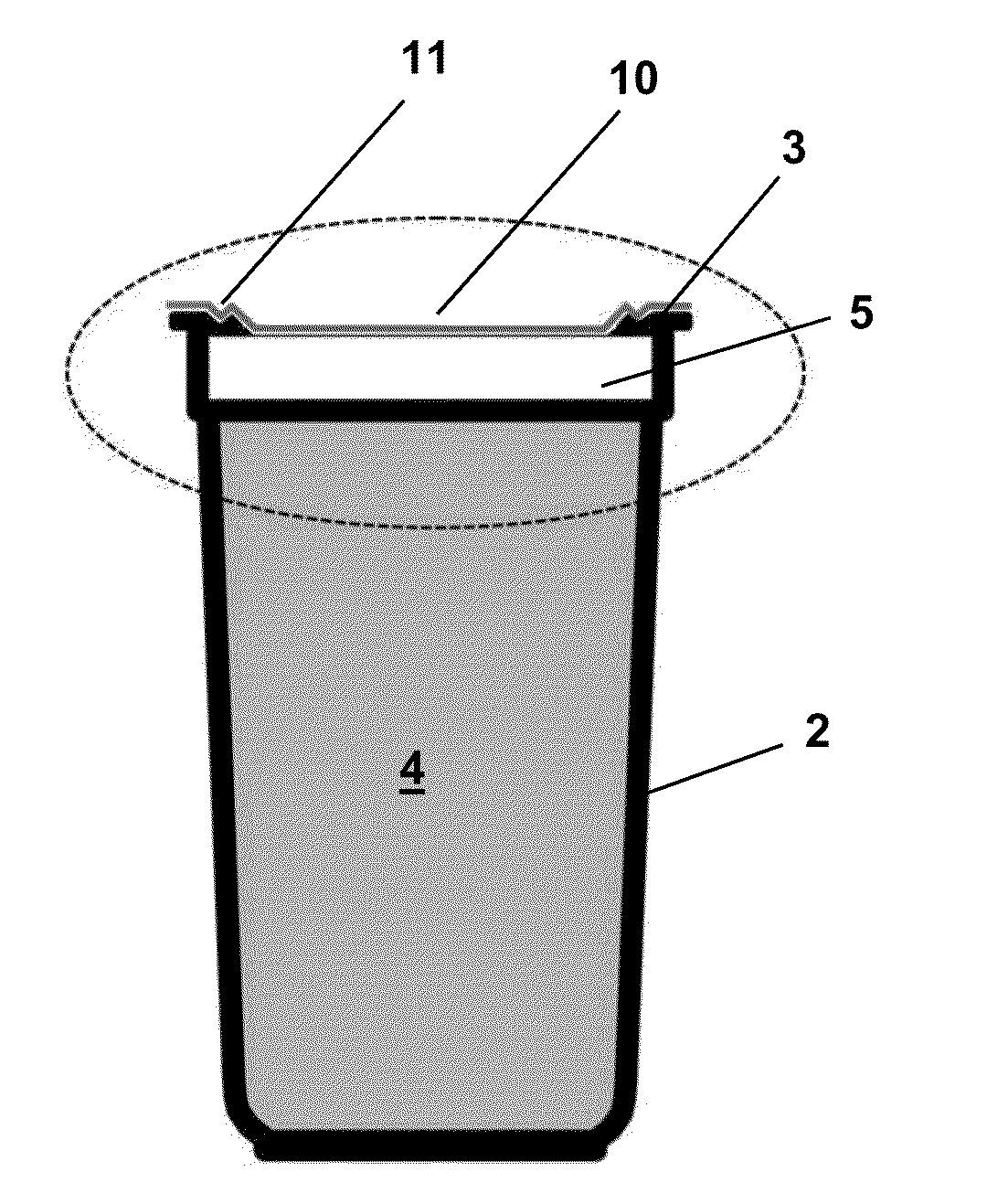

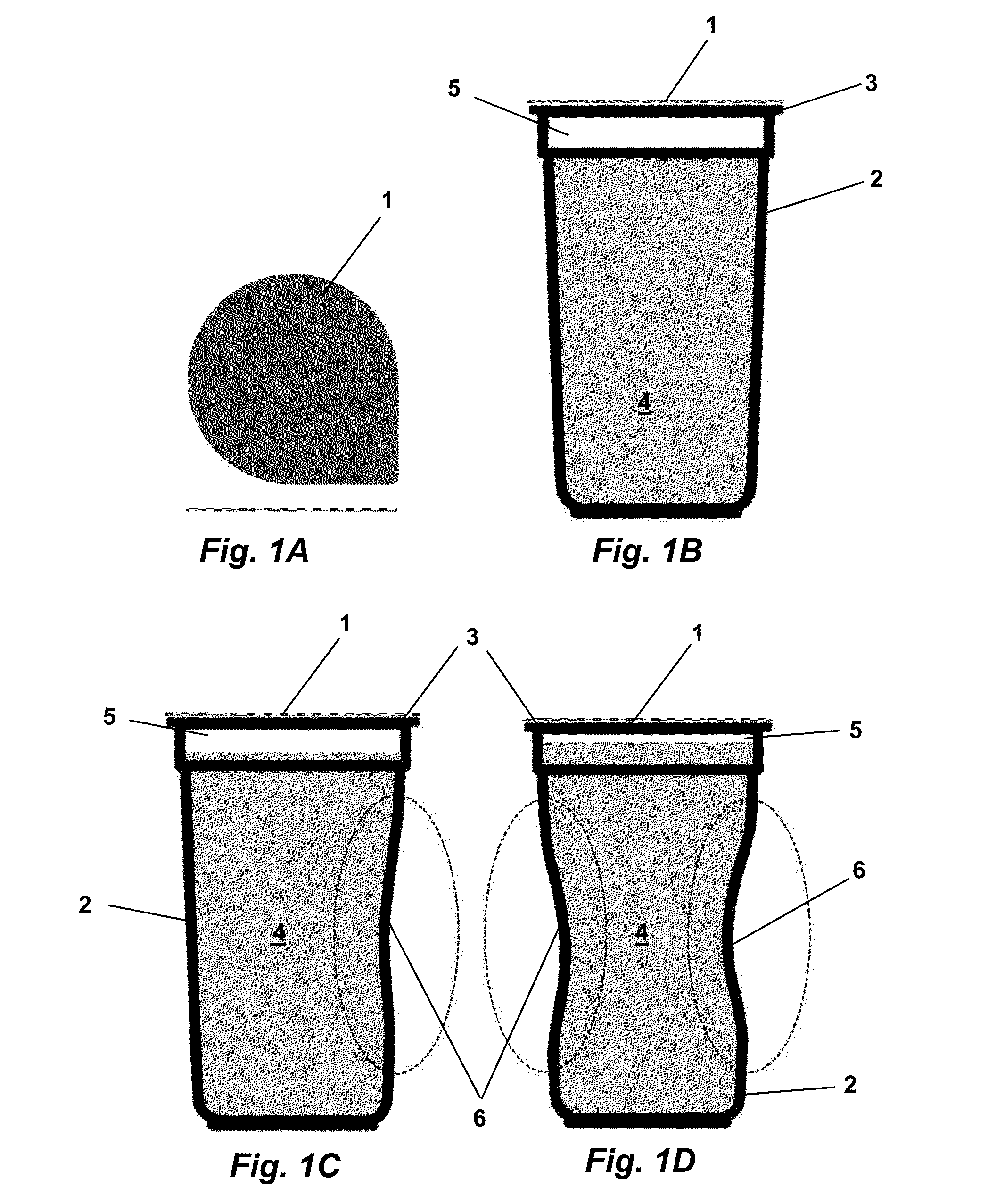

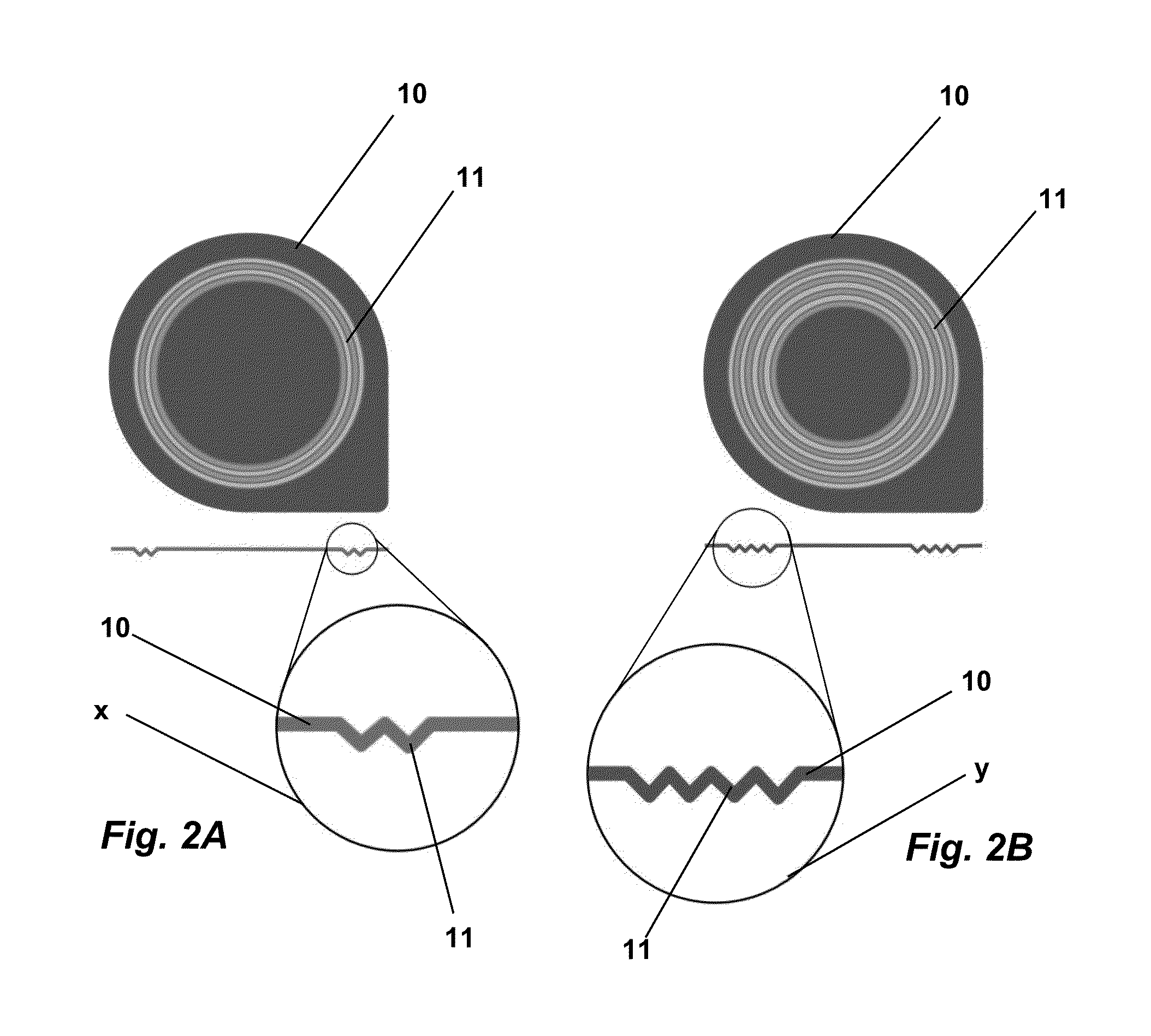

[0036]Merely as an illustration, FIGS. 1A to 1D illustrate conventional realizations of a lid and pack as known in the state of the art. FIG. 1A shows a lid 1 comprising an aluminum sheet and a layer of polyethylene, polypropylene or thermo-sealing varnish. As illustrated in FIG. 1B, the above-mentioned lid 1 is placed on the open end 3 of the pack 2 after it is filled with a beverage 4 at a temperature of around 30° C. to 35°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com