Laminate Tube Having a Resilent Copolymer Coating

a copolymer coating and laminate tube technology, applied in the field of laminate tube having a resilent copolymer coating, can solve the problems of reducing the volume of oils embodied in most dentifrices, affecting the taste of dentifrices, and certain products after a time that have been noted to deteriorate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

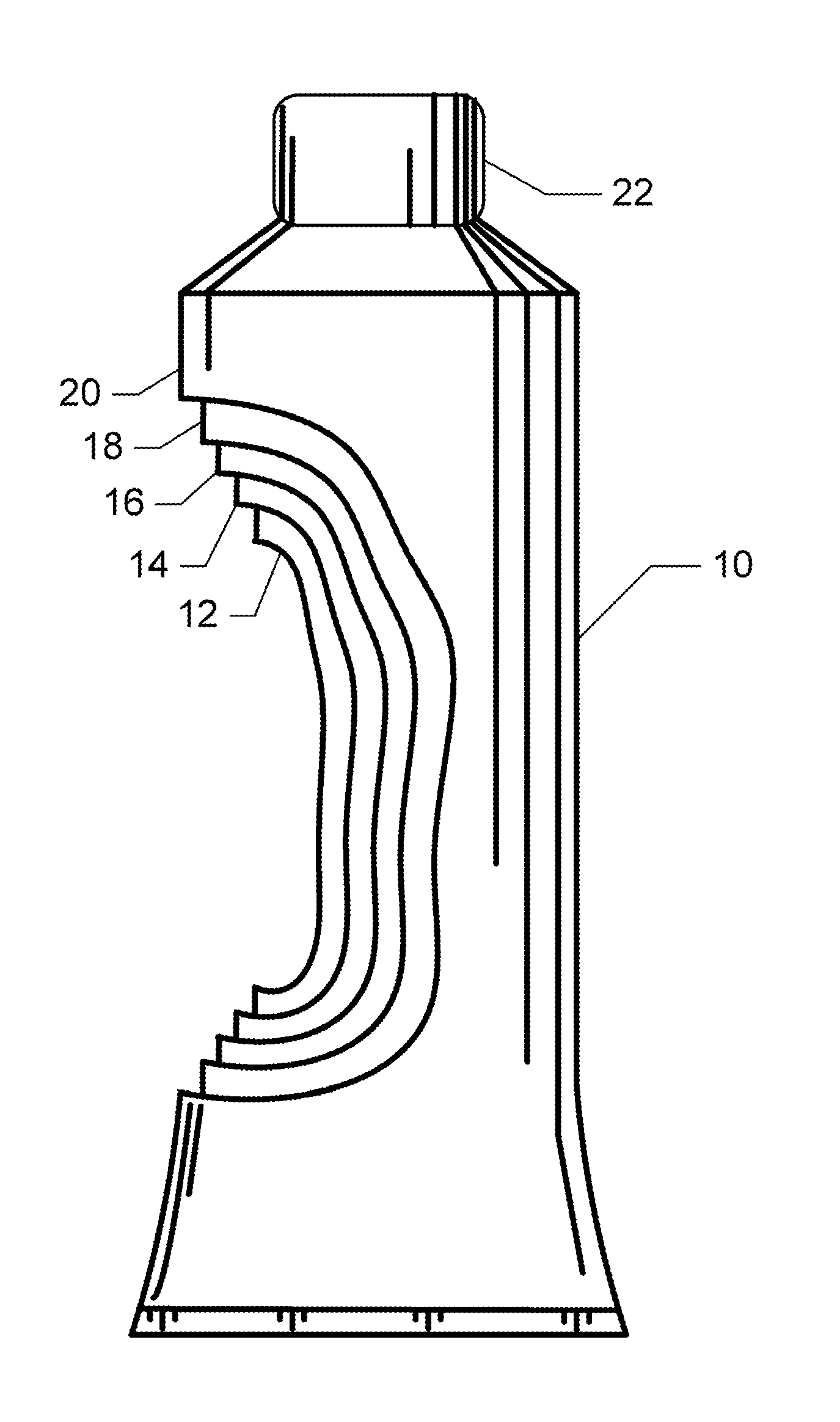

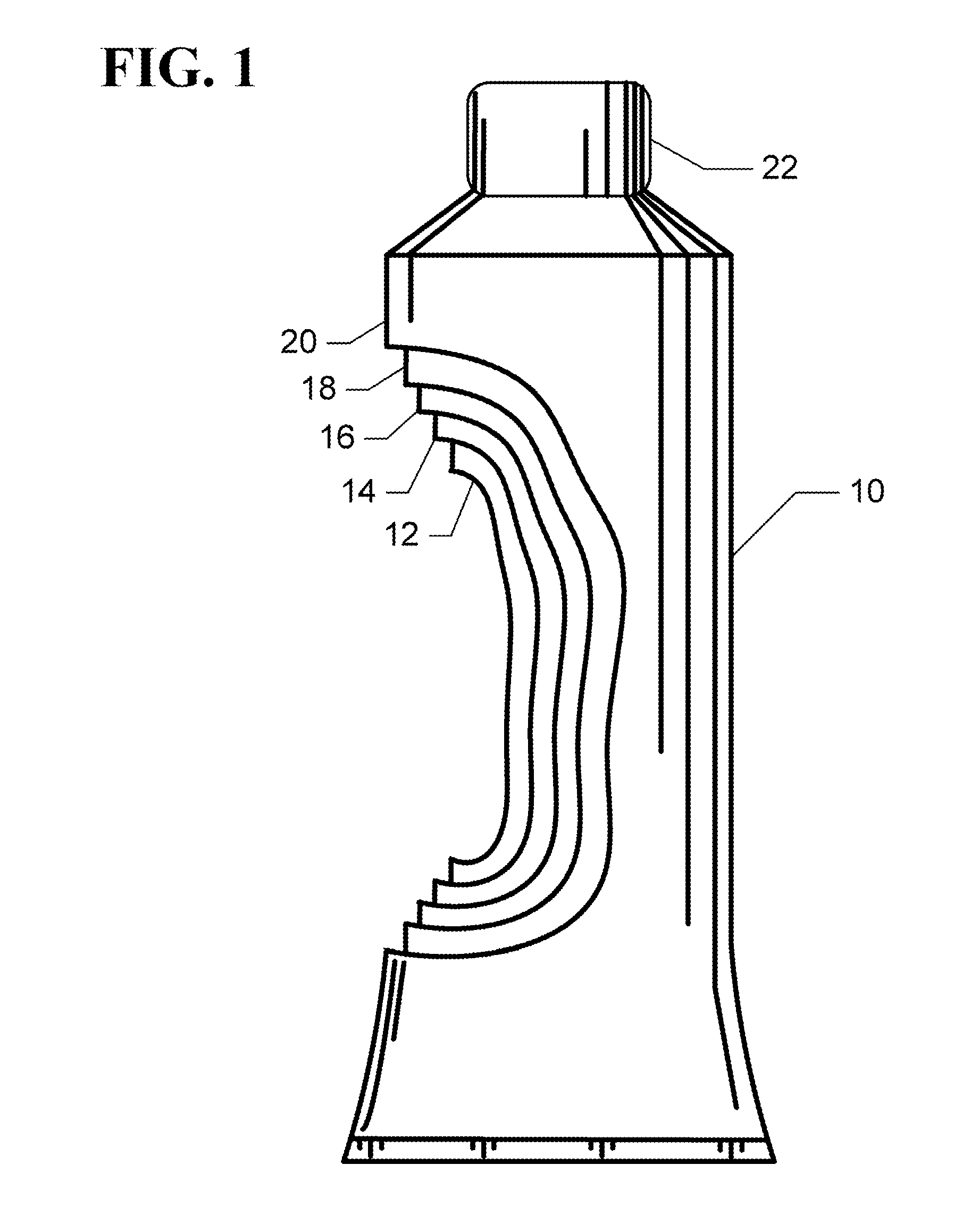

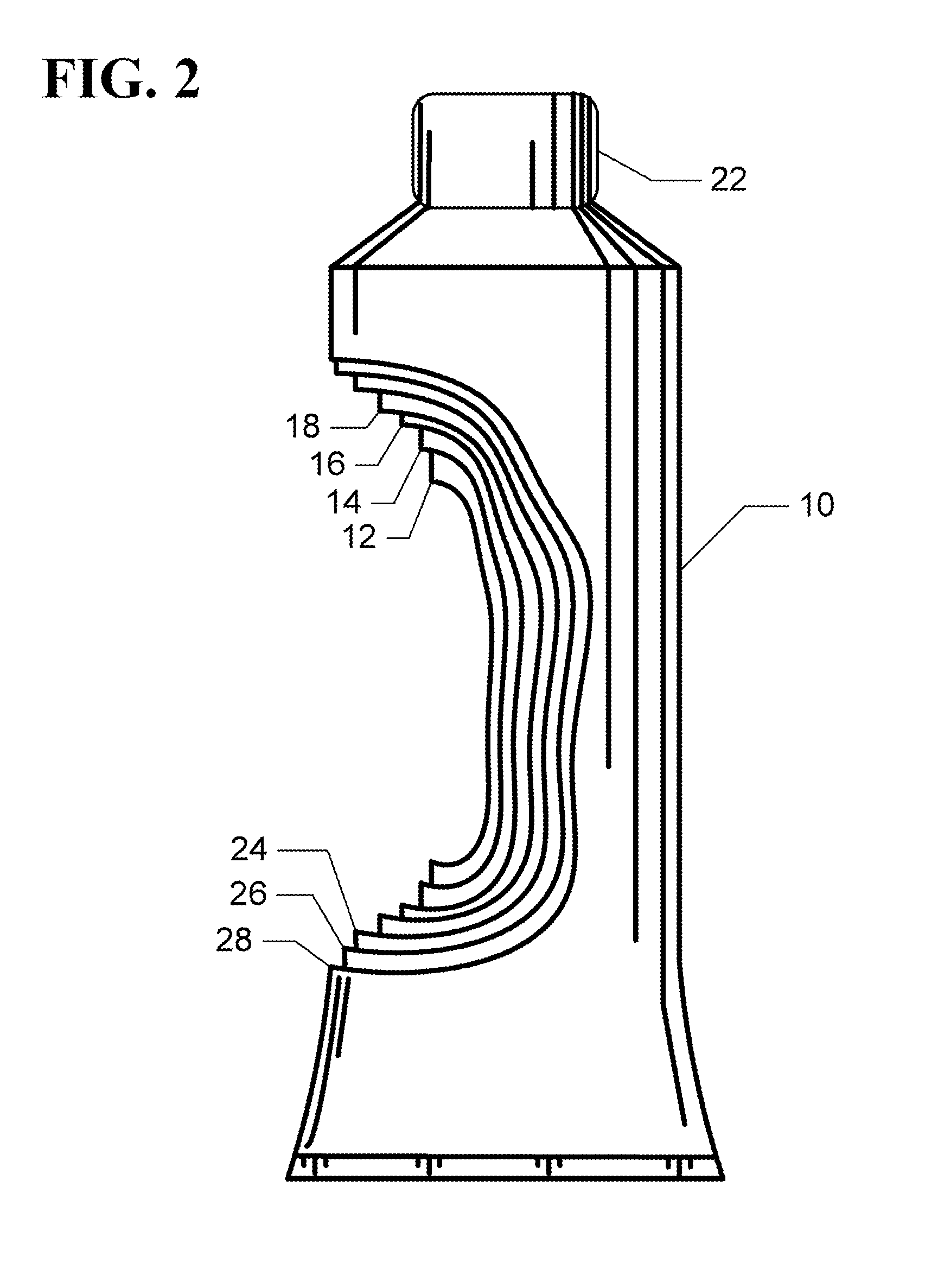

Image

Examples

example 1

[0070]A three-layer film with a total thickness of 120 microns was blown according to the outer film structure (24 / 26 / 28) shown in Table 2.

[0071]Impact resistance testing showed that the impact resistance of this film was 376 g. (All impact resistance values referenced herein are measured and defined in accordance with Chinese State Standard GB 9639-88: “Impact Resistance Test of Plastic Film and Sheet”, which is equivalent to ISO 7765-85.)

example 2

[0076]A one-layer film with a total thickness of 120 microns was blown according to the outer film structure (20) shown in Table 1. The film had an impact resistance of 182 g, 20% greater than the film of Comparative Example 1.

[0077]Thus, the invention provides films, laminates and dispensers with enhanced impact resistance. In certain embodiments, a laminate (or film) of the invention having a thickness of 120 microns has an impact resistance greater than 152 g or greater than 160 g or greater than 180 g or greater than 200 g or greater than 300 g or greater than 375 g. In certain of these embodiments, the 120 μm laminate (or film) of the invention has an impact resistance less than 1000 g or less than 750 g or less than 500 g, and preferably has an impact resistance of 180-400 g. In certain embodiments, a laminate (or film) of the invention has an impact resistance at least 5% or at least 10% or at least 20% or at least 50% greater than a reference structure. As used herein, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com