Combustion of Oil From a Marine Oil Spill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

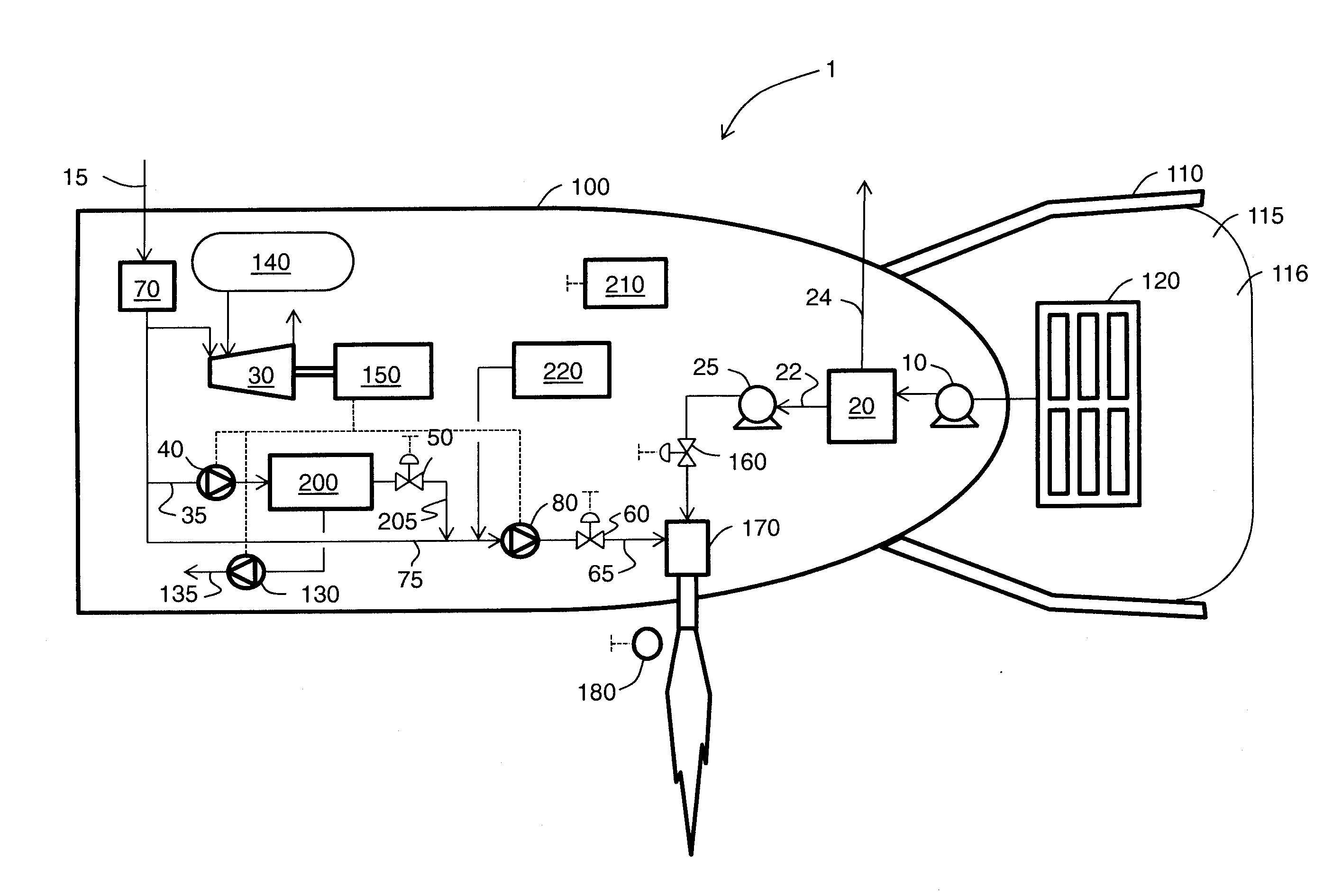

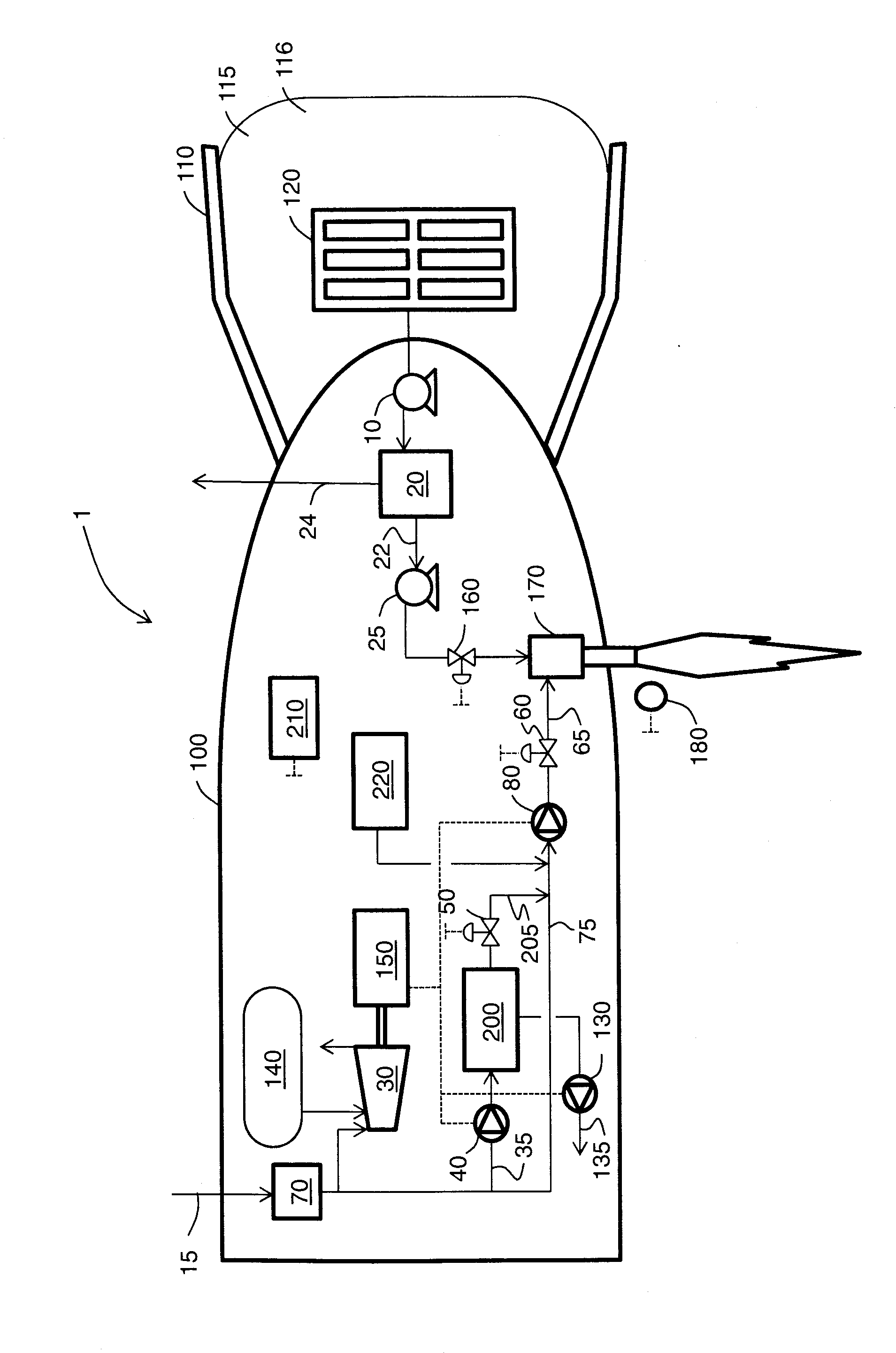

Image

Examples

example

[0089]The stoichiometric oxygen requirement for combusting 200 BPH (barrels per hour) oil flow rate is calculated to be about 60,000 Nm3 / hr. If the stoichiometric amount of oxygen is supplied by injecting compressed air, the compressed air flow rate is about 285,000 Nm3 / hr.

[0090]If the stoichiometric amount of oxygen is supplied by injecting an oxygen-containing gas wherein the oxygen-containing gas has 50 volume % oxygen, the total flow rate of the oxygen-containing gas is about 204,000 Nm3 / hr. The flow rate of substantially pure industrial oxygen (90-93 vol. % O2, typical VSA quality) is about 24,000 Nm3 / hr and the balance compressed air.

[0091]If half of the stoichiometric amount oxygen is supplied by injecting an oxygen-containing gas wherein the oxygen-containing gas has 50 volume % oxygen, the total flow rate of the oxygen-containing gas is about 102,000 Nm3 / hr. The flow rate of substantially pure industrial oxygen (90-93% VSA spec) is about 12,000 Nm3 / hr and the balance compre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap