Nanofiber manufacturing device

a manufacturing device and nanofiber technology, applied in the field of nanofiber manufacturing equipment, can solve the problems of difficult continuous operation of the electrospinning device, increased leak current to an undesirable level, and caused by the breakdown of the insulation between the collector and the case and other members, and achieve the effect of stably producing nanofibers, simple structure and shap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

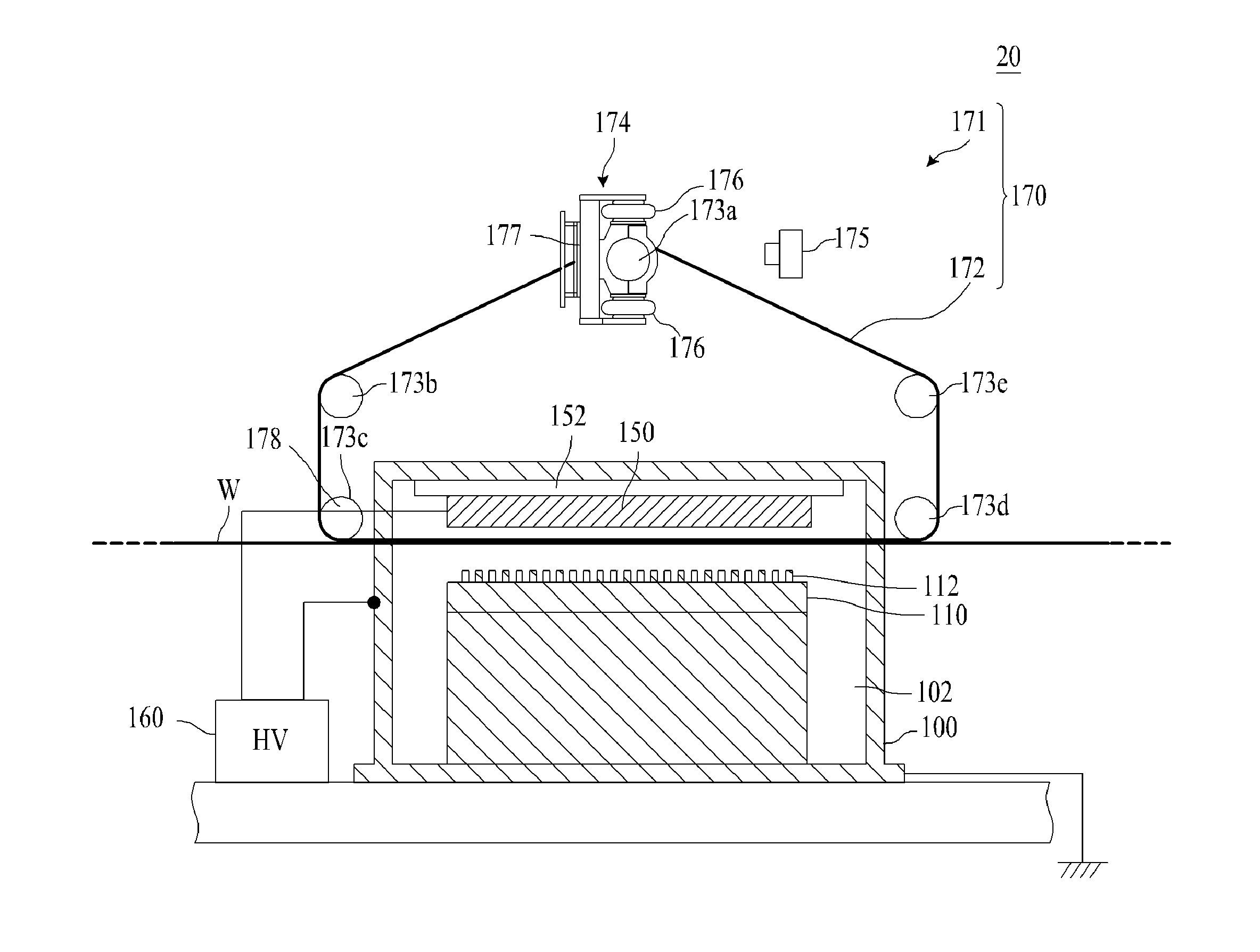

[0098]FIGS. 1a and 1b are front and plan views showing a nanofiber manufacturing apparatus according to a first embodiment of the present invention. FIG. 1a is a front view showing the nanofiber manufacturing apparatus 1 and FIG. 1b is a plan view showing the nanofiber manufacturing apparatus 1. In FIGS. 1a and 1b, a polymer solution supply unit and a polymer solution collection unit are not shown. Further, some parts of FIG. 1a are shown in FIG. 2.

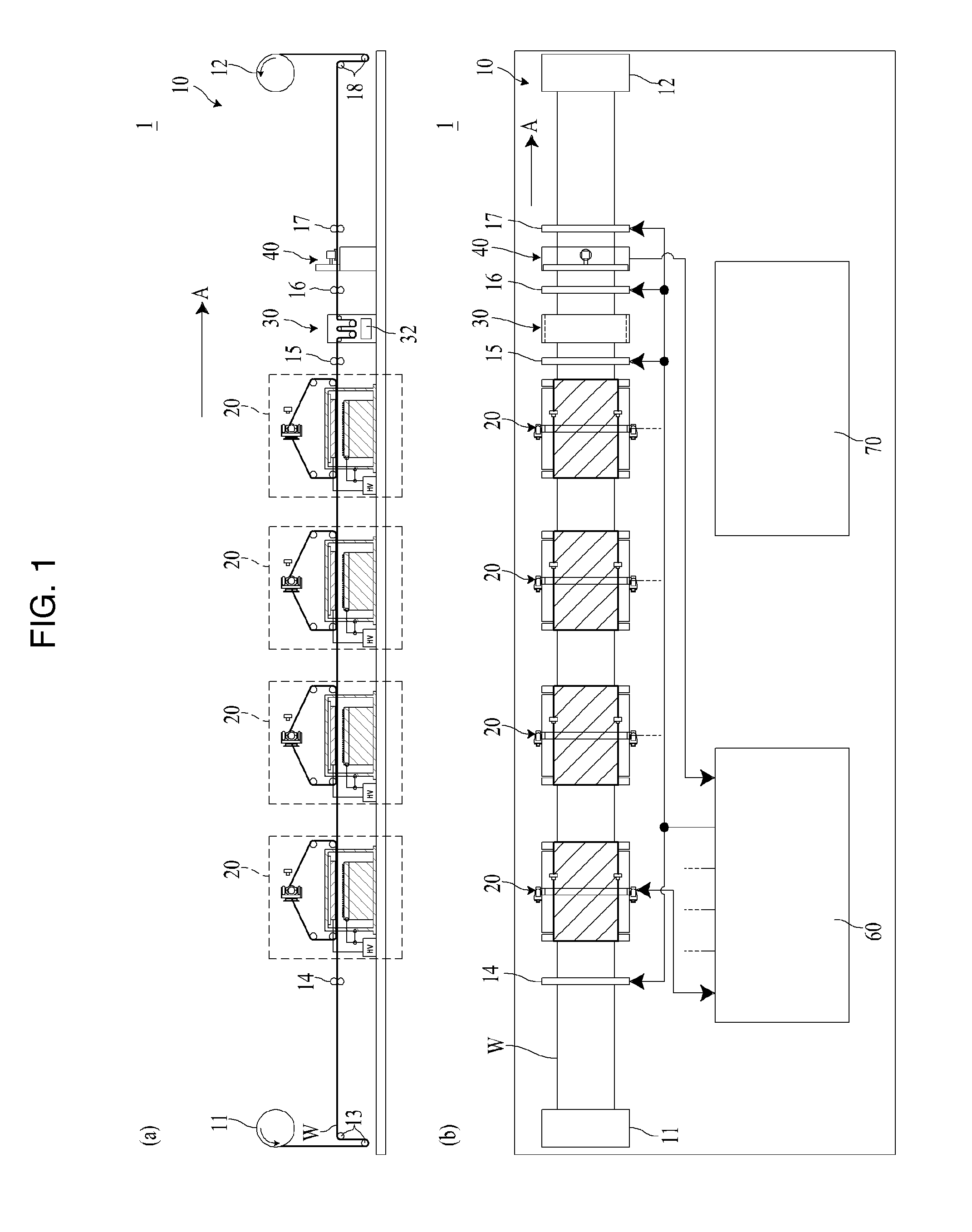

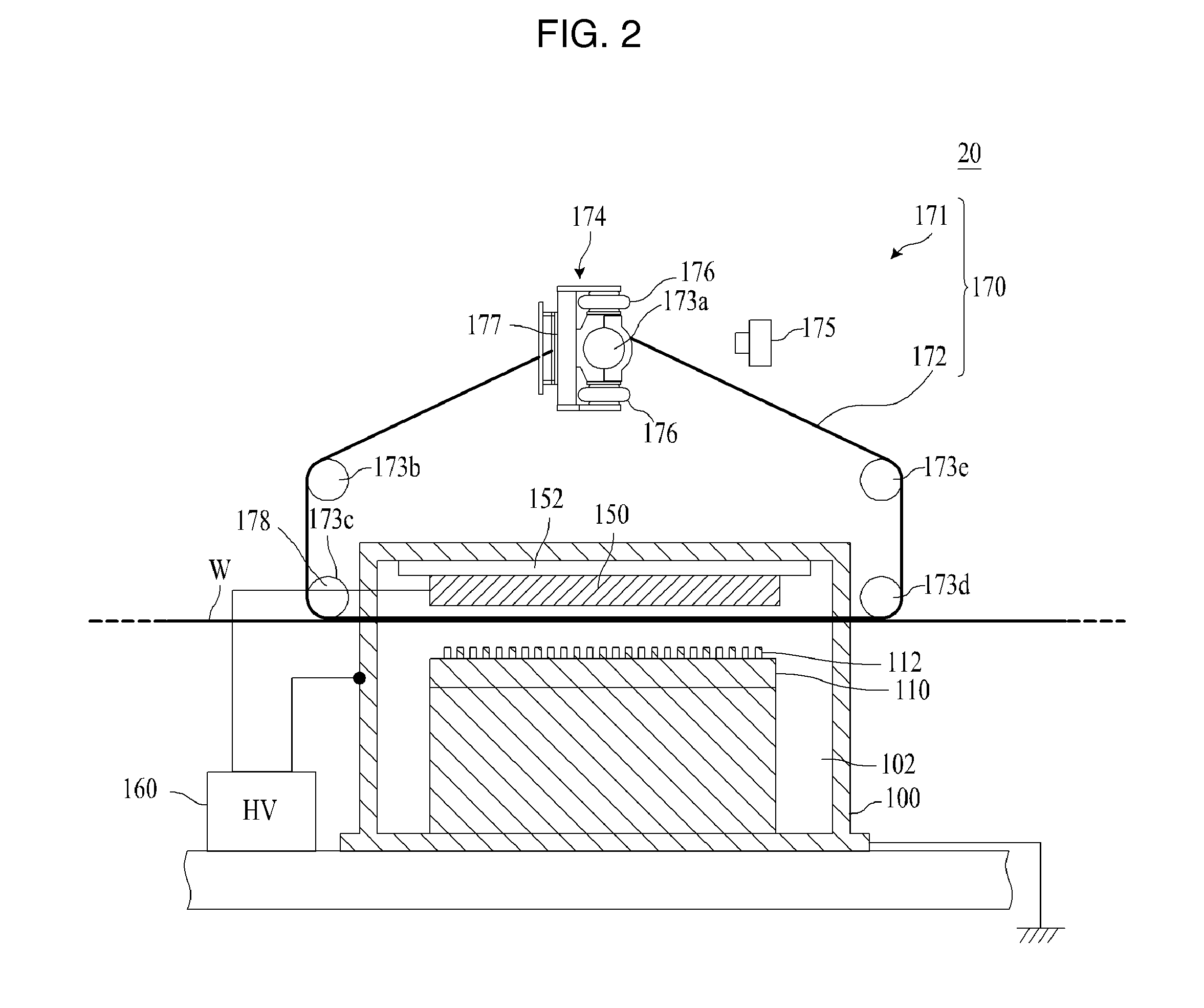

[0099]FIG. 2 is a sectional view showing an electrospinning unit used in the nanofiber manufacturing apparatus according to the first embodiment of the present invention.

[0100]FIGS. 3a and 3b are enlarged sectional and plan views showing the main parts of the electrospinning unit, wherein FIG. 3a is an enlarged sectional view showing the main parts of the electrospinning unit and FIG. 3b is an enlarged plan view showing the main parts of the electrospinning unit. FIG. 4 is a sectional view showing an auxiliary belt unit moved in a conveyi...

example 1

[0134]Example 1 is the experimental example clearly showing the appropriate thickness a of the insulation member 152, so as to stop the leak current at the given range. Table 1 shows the experimental results of the example 1, and FIG. 8 is a graph showing the experimental results of the example 1.

TABLE 1a =a =a = 5 mma = 6 mma = 8 mm10 mm12 mmmAkVmAkVmAkVmAkVmAkV0.0129.80.0137.20.0141.00.0143.00.0146.30.0234.40.0244.30.0246.60.0249.00.0254.00.030.0349.10.0354.80.0356.00.0359.00.040.0450.30.0459.70.040.04Insu-36.053.4lationBreak-down*b is fixed to 30 mm

[0135]In the example 1, in the state where the polymer solution was not fed to the nozzle block 110 in the nanofiber manufacturing apparatus 1 according to the present invention (wherein, the thickness a was set to 5 mm, 6 mm, 8 mm, 10 mm or 12 mm, and the distance b was fixed to 30 mm), the voltage was applied between the collector 150 and the nozzle block 110 to allow a given current supplied from the power supply 160 to become a giv...

example 2

[0137]Example 2 is the experimental example clearly showing the appropriate distance a+b between the insulation member 152 and the collector 150, so as to stop the leak current at the given range. Table 2 shows the experimental results of the example 2, and FIG. 9 is a graph showing the experimental results of the example 2.

TABLE 2mAkVmAkVmAkVmAkVa + b =a + b =a + b =a + b =45 mm50 mm60 mm80 mm0.0132.20.0137.00.0139.20.0140.30.0234.80.0237.30.0250.20.0250.70.0336.30.0340.80.030.0353.00.0437.00.0442.60.040.0456.50.05—0.05—0.050.05Insulation—46.054.058.8Break-downa + b =a + b =a + b =a + b =100 mm120 mm140 mm160 mm0.0141.20.0141.70.0141.80.0142.80.0250.90.0252.70.0255.30.0257.10.0354.80.0360.30.0360.50.0360.80.0457.30.04—0.04—0.04—0.0560.70.05—0.05—0.05—Insulation————Break-down*a is fixed to 40 mm

[0138]In the example 2, in the state where the polymer solution was not fed to the nozzle block 110 in the nanofiber manufacturing apparatus 1 according to the present invention (wherein, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com