Capsule for non-ferrous metal collection and method of collecting non-ferrous metal

a non-ferrous metal and capsule technology, applied in the field of capsules for non-ferrous metal collection and non-ferrous metal collection, can solve the problems of large amount of waste solvent generated, large amount of energy accompanied by consumption, and cost of constructing recovery systems, etc., to achieve effective concentrated and collected, easy to collect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

Method of Manufacturing Capsule for Collecting Non-Ferrous Metal Having Three-Layered Structure (Second Embodiment)

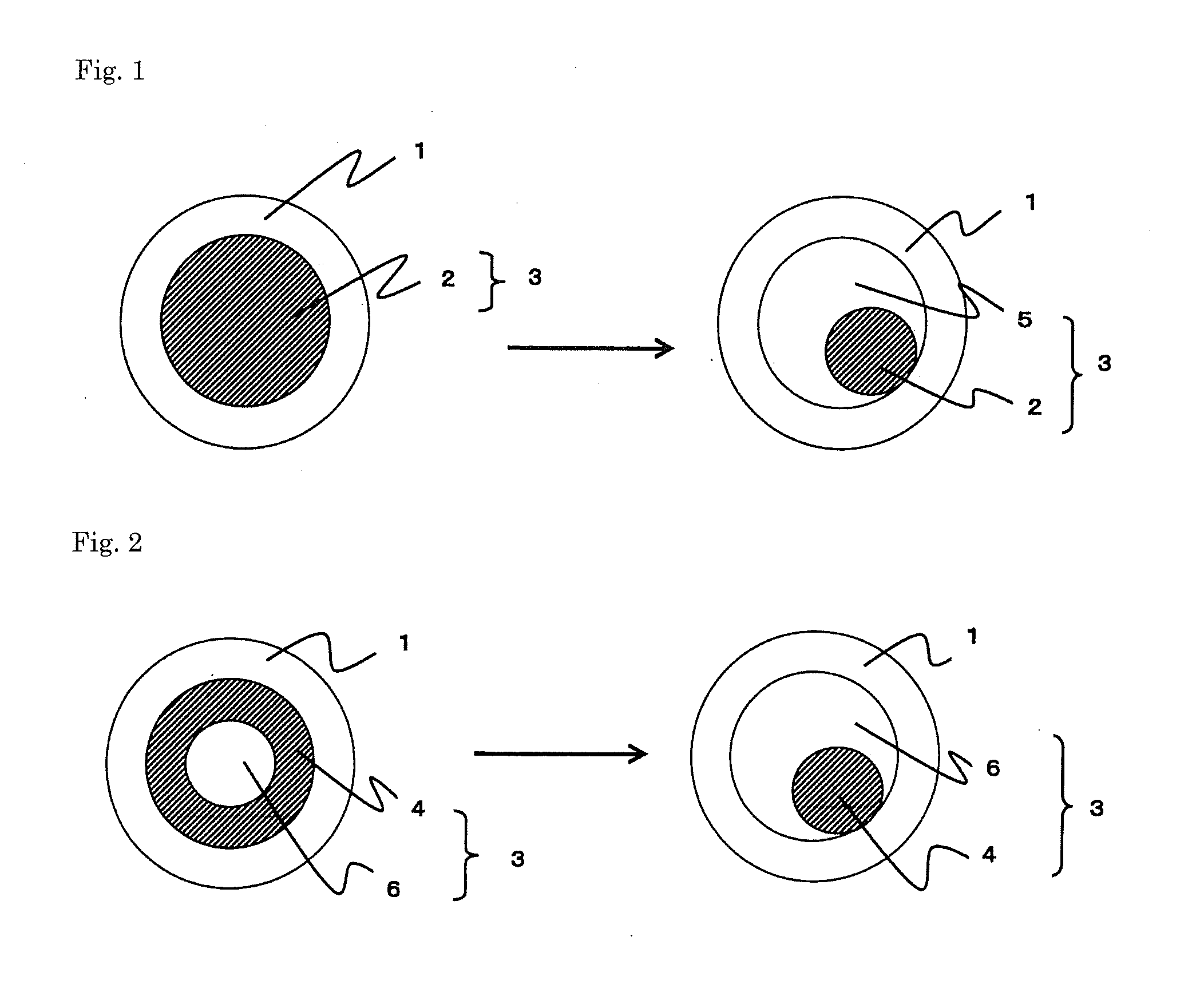

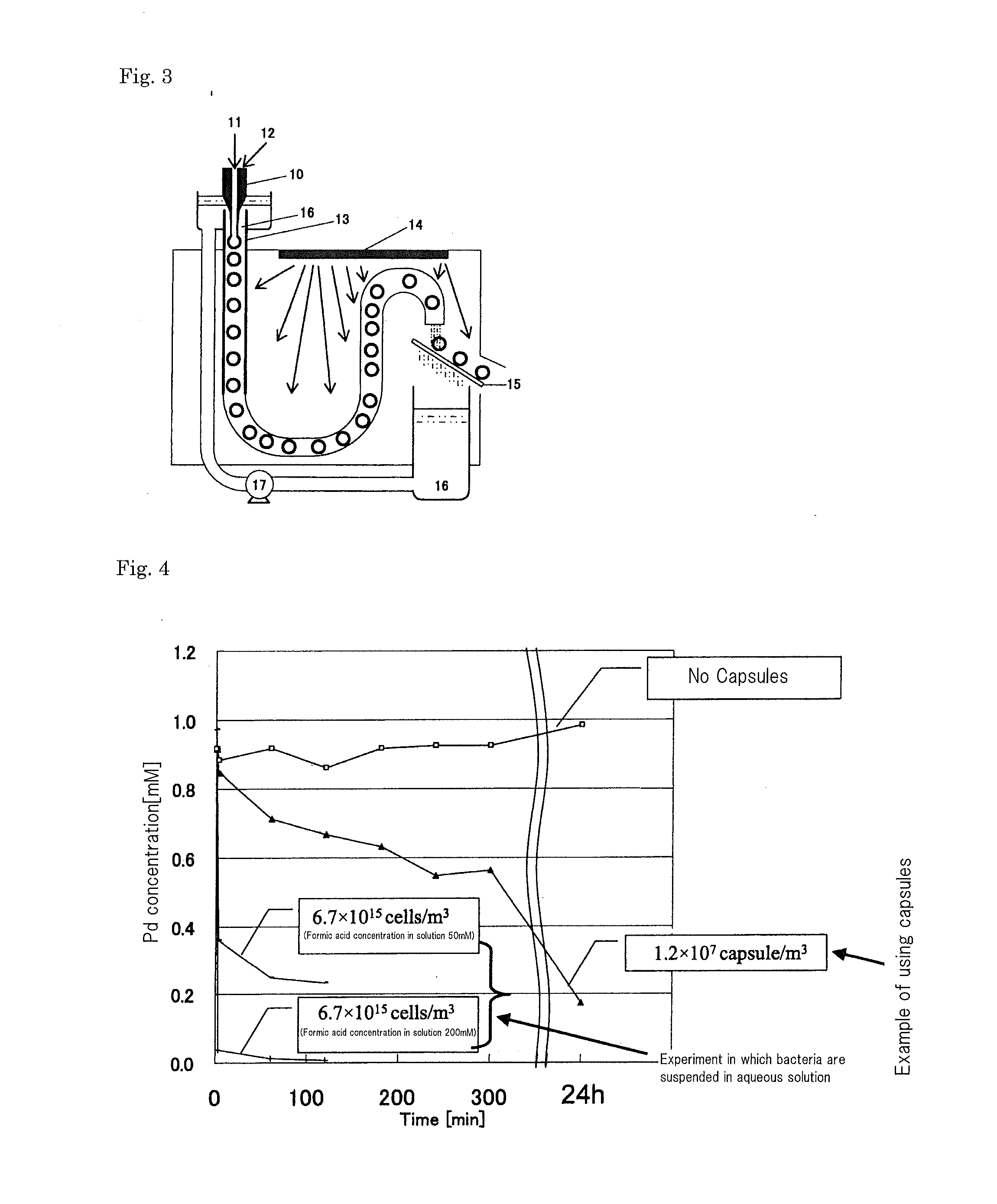

[0121]A left drawing of FIG. 2 is a schematic view showing a capsule for collecting a non-ferrous metal having a three-layered structure immediately after manufacturing. The capsule for collecting a non-ferrous metal of the present invention having a three-layered structure (second embodiment) shown in this FIG. 2 can be manufactured, for example, by an in-liquid dropwise addition method, using a conventionally known capsule manufacturing apparatus, in which the concentric double nozzle is changed to a concentric triple nozzle, shown in FIG. 3. Specifically, the capsule for collecting a non-ferrous metal having a three-layered structure can be manufactured by using a capsule manufacturing apparatus provided with a concentric triple nozzle having a first nozzle (innermost portion), a second nozzle (intermediate portion) and a third nozzle (outermost portion) to extrude a...

example 1

[0144]Example 1 is a capsule for collecting a non-ferrous metal having a two-layered structure immediately after manufacturing, in which a capsule content is an oily portion containing Shewanella bacteria, and a shell covering the capsule content is obtained by curing a shell formation composition containing a hydrophilic photocurable component.

[0145]The shell formation composition was prepared by mixing 60 parts by mass of a 40% aqueous solution of ENTG-3800 (manufactured by Kansai Paint Co., Ltd.), 0.6 parts by mass of acetoin, and 20 parts by mass of a 0.5% aqueous poval solution.

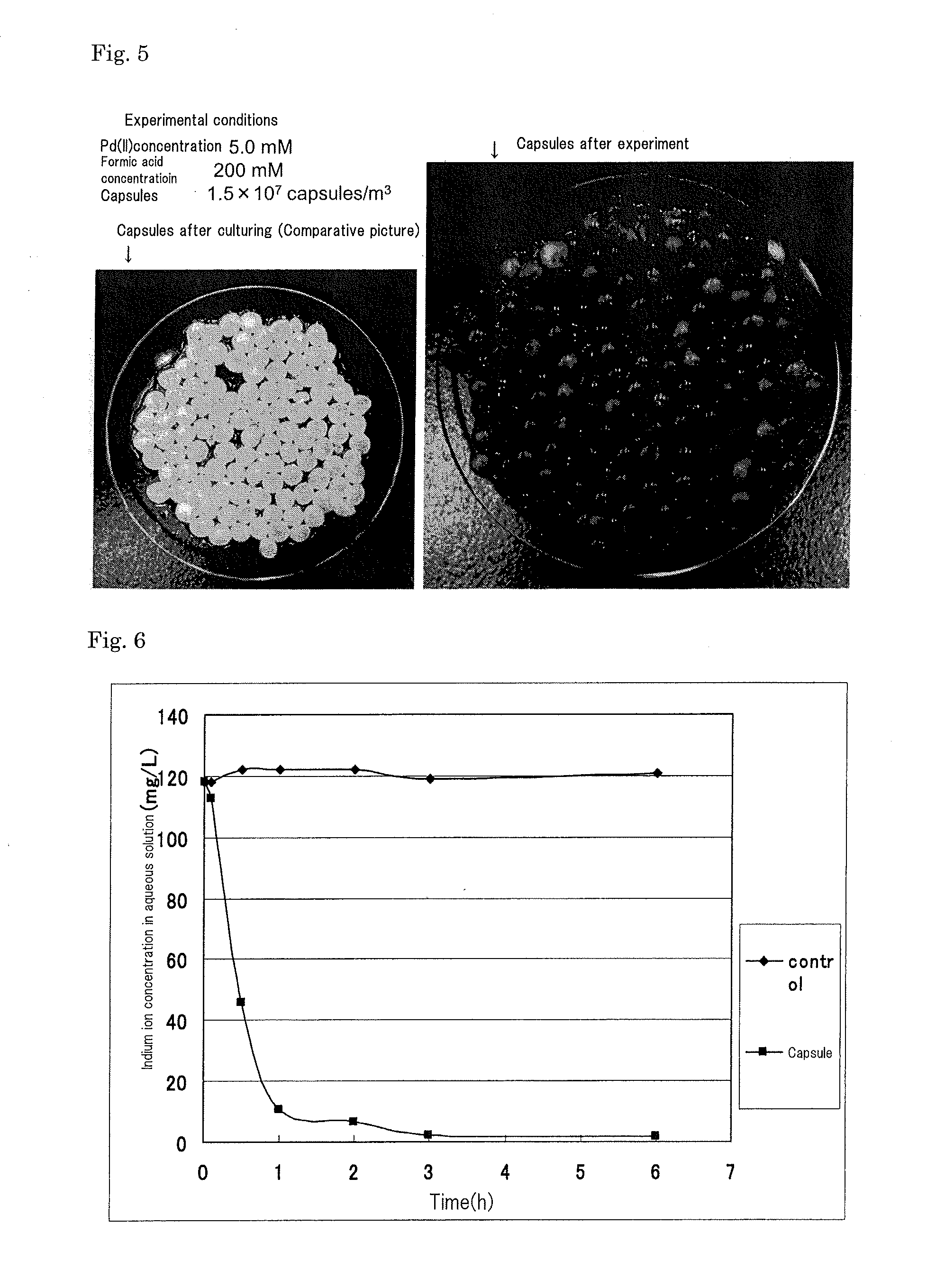

[0146]The capsule content was prepared by dispersing and suspending Shewanella oneidensis being reducing bacteria cultured at a high concentration in coconut oil being an oily substance, to prepare a suspension composition in which a concentration was adjusted to 1.2×108 cells / capsule per one capsule.

[0147]Then, the capsules were obtained using an apparatus having a concentric double nozzle (a seamless c...

example 2

[0148]Example 2 is a capsule for collecting a non-ferrous metal having a three-layered structure immediately after manufacturing, in which a capsule content is a hydrophilic portion containing Shewanella bacteria, a shell covering the capsule content is obtained by curing a shell formation composition containing a hydrophilic photocurable component, and an intermediate layer is made of an oily substance.

[0149]The shell formation composition was prepared by mixing 60 parts by mass of a 40% aqueous solution of ENTG-3800 (manufactured by Kansai Paint Co., Ltd.), 0.6 parts by mass of acetoin, and 20 parts by mass of a 0.5% aqueous poval solution.

[0150]The capsule content was prepared from a hydrophilic internal layer composition in which a concentration of Shewanella oneidensis being a reducing bacterium cultured at a high concentration was adjusted so that the bacterium was contained in a hydrophilic solution culture medium at 1.2×108 cells / capsule per one capsule.

[0151]The intermediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com