Dry scrubber system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

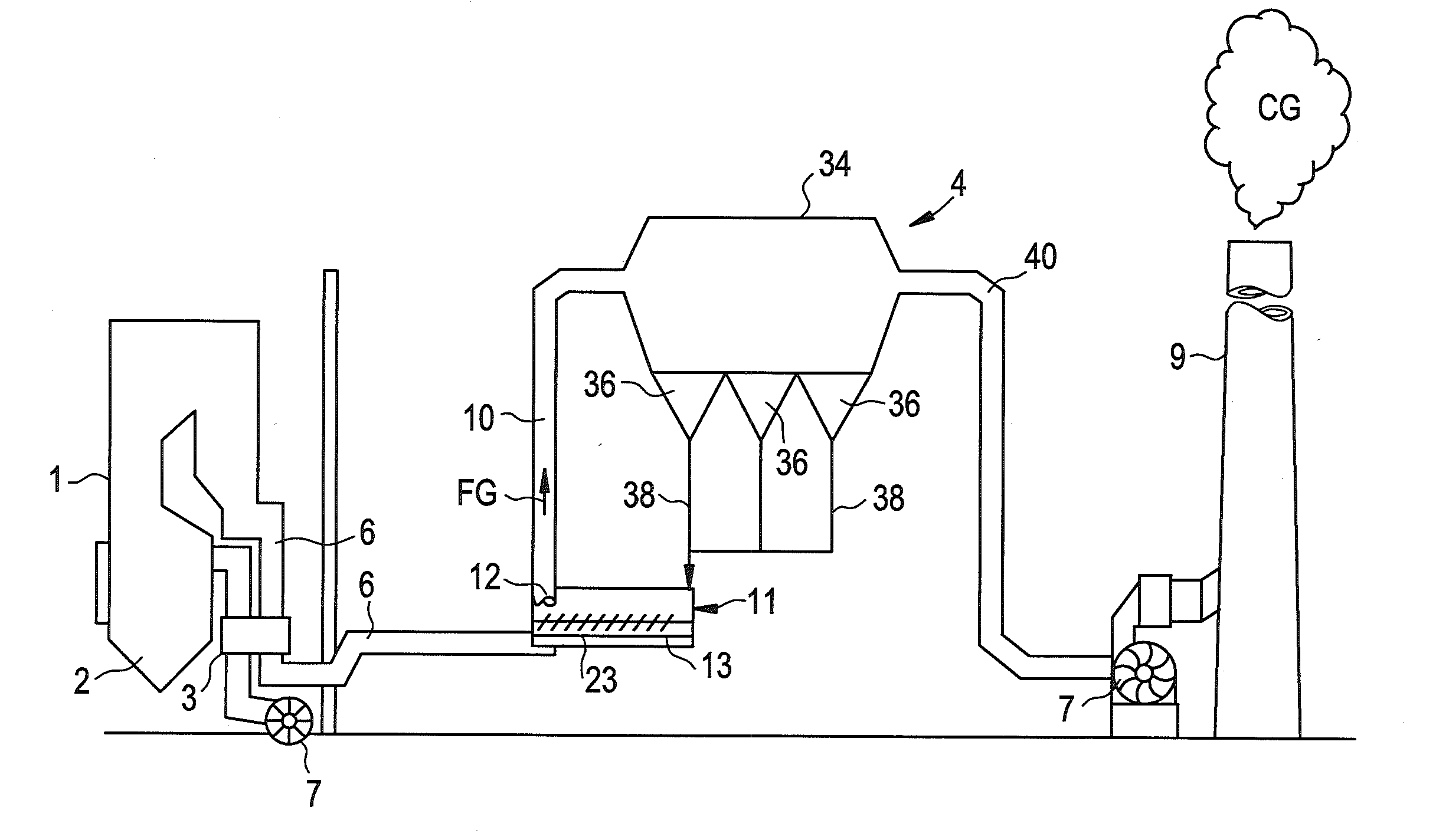

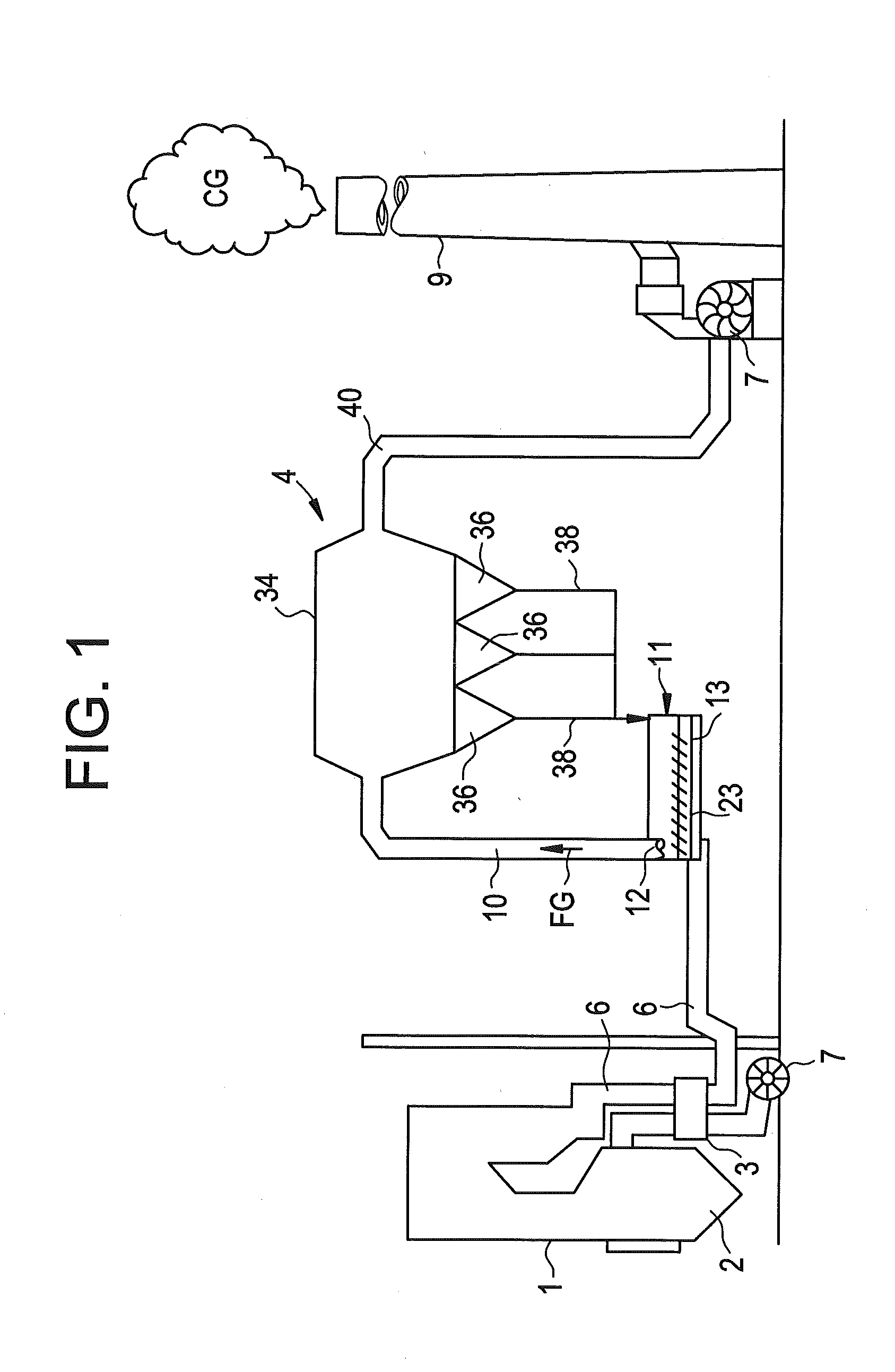

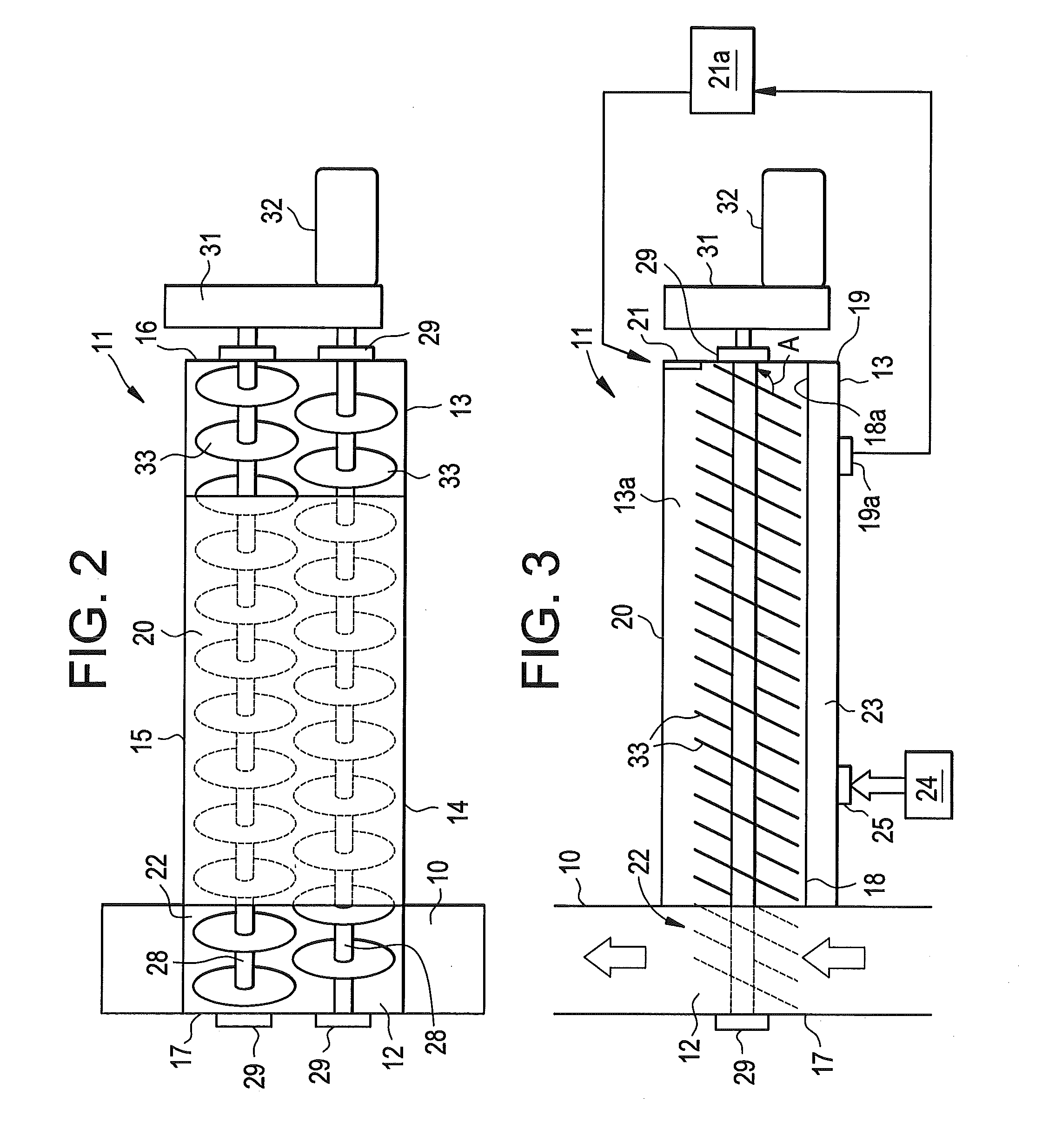

[0014]One embodiment, generally depicted in FIG. 1 as a process schematic diagram that includes a boiler 2, an air quality control system (AQCS) 4 and a stack 9. It is noted that many additional and varied process steps using additional equipment may be positioned or take place between boiler 2 and AQCS 4, as is known to those skilled in the art. Likewise, many additional and varied process steps using additional equipment may be positioned or take place following AQCS 4 and prior to environmental release of a “cleaned” flue gas, CG, from stack 9, as is known to those skilled in the art. Such additional process steps and / or equipment are not described in further detail herein for purposes of clarity and simplicity.

[0015]As noted previously, FIG. 1 illustrates schematically an AQCS 4 for cleaning dirty flue gases, FG, from a plant 1 conducting a combustion process, such as those from a fossil fuel-fired or coal-fired boiler 2. The hot flue gases containing SO2, SO3, HCl, HF, fly ash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com