Electrolytic solution, electrolysis case, electropolishing system, and electropolishing method using these

a technology of electrolysis solution and electrolysis case, which is applied in the field of electrolysis solution, can solve the problems of high equipment renewal cost, high cost, and difficult operation, and achieve the effects of reducing workload, shortening operation time, and holding viscous electrolytic solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

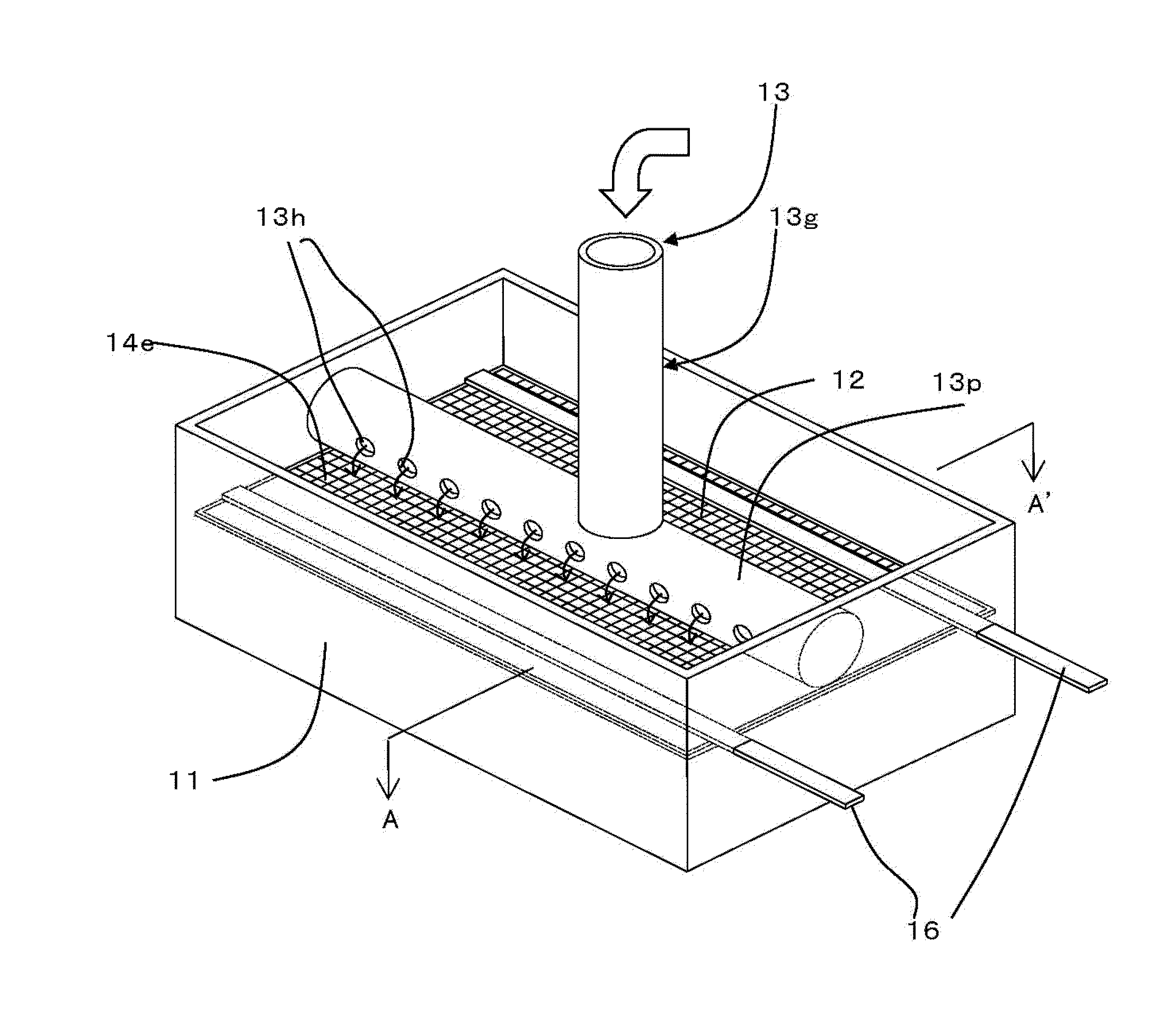

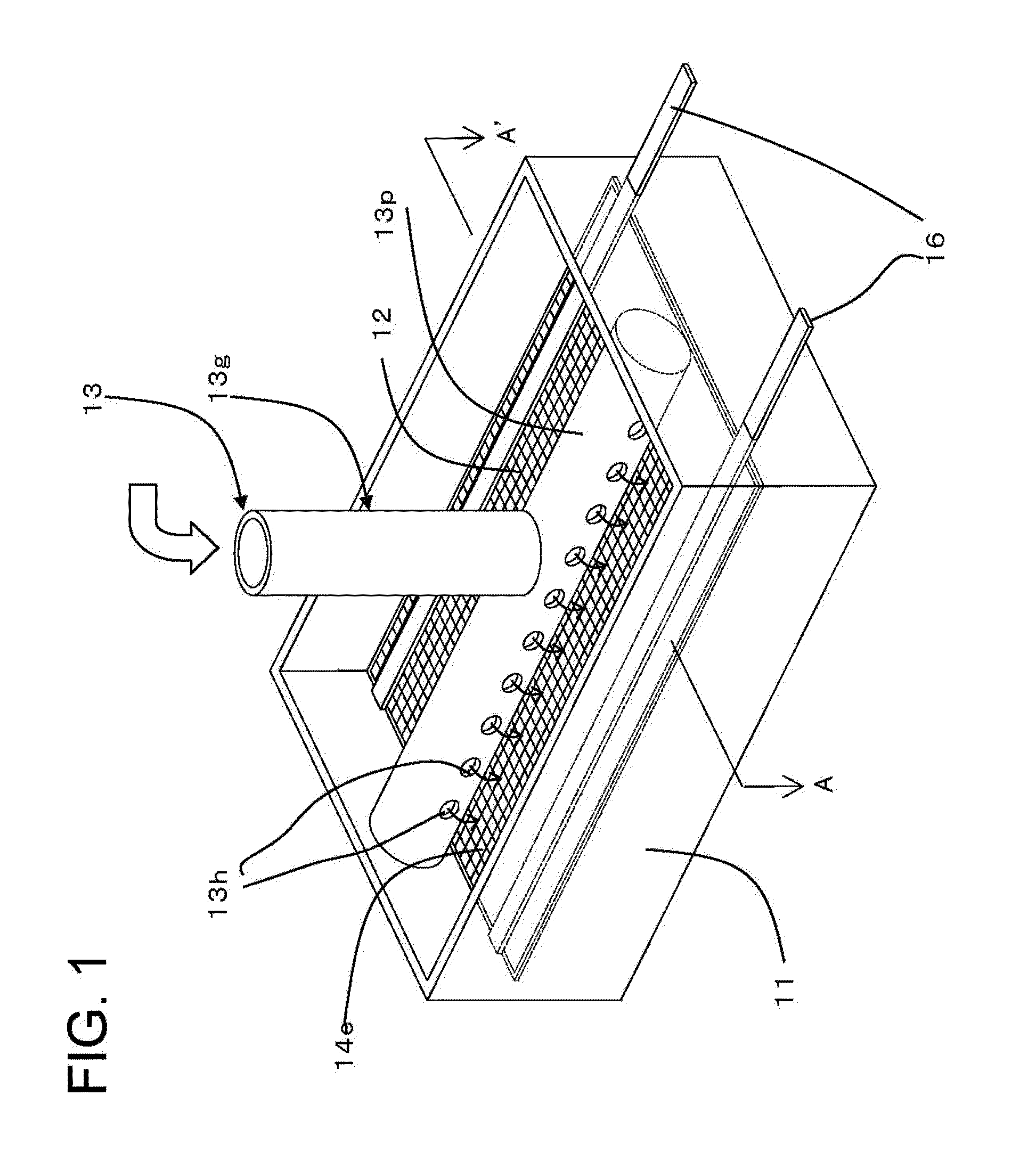

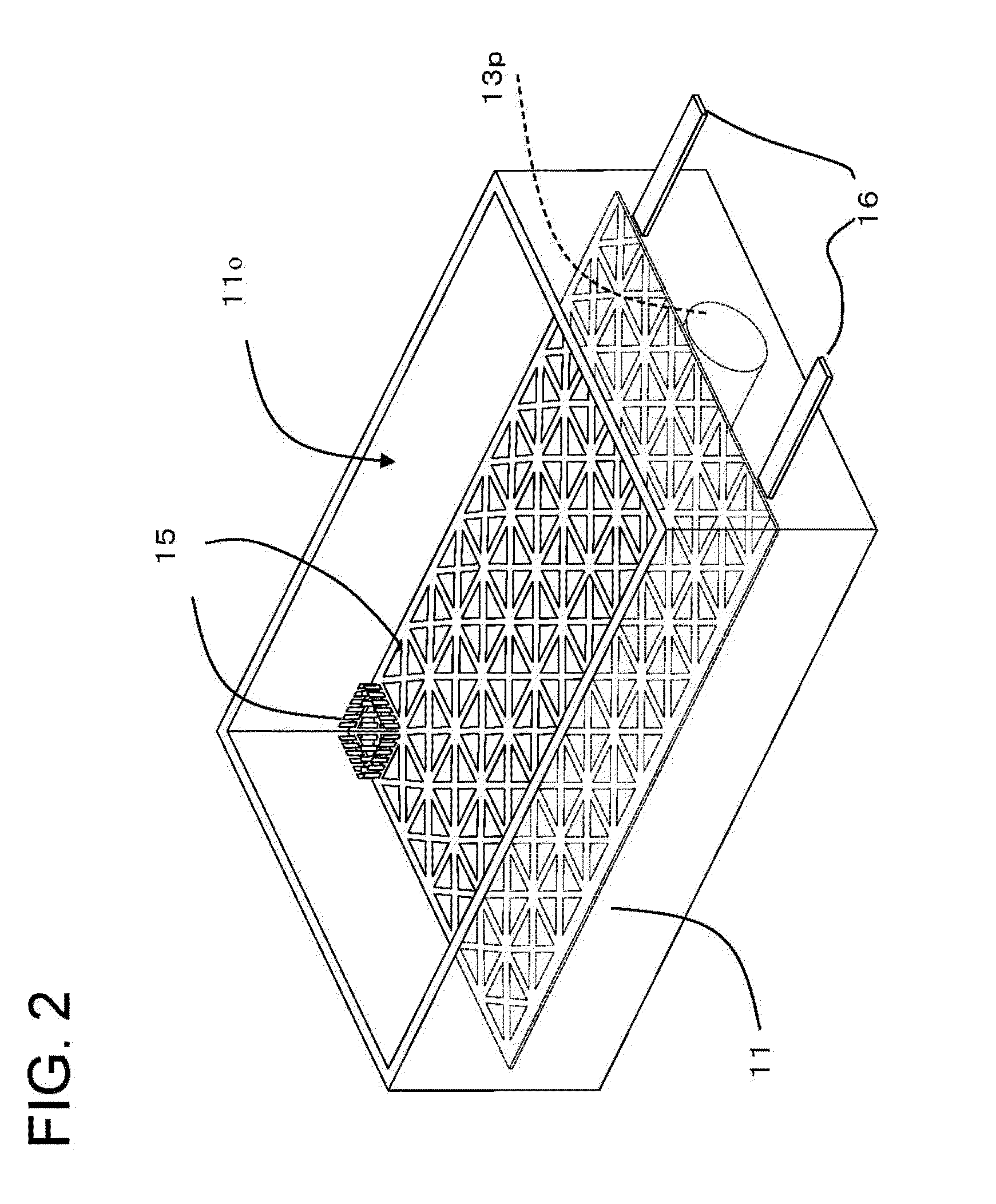

Image

Examples

embodiment 1

[0045]

[0046]The following electrolytic solutions are prepared.[0047](1) Electrolytic solutions (b), (c), and (f) for comparative tests, (which is referred to as a normal solution, hereinafter.)

[0048]85% phosphoric acid: 750 mL / L

[0049]98% sulfuric acid: 250 mL / L[0050](2) Electrolytic solution used to the present invention, (which is referred to a high-viscous solution, hereinafter.)

[0051]85% phosphoric acid: 750 mL / L

[0052]98% sulfuric acid: 250 mL / L

[0053]SiO2.XH2O: 200 g / L

[0054]

[0055]Test pieces, SUS 316L, (30×30×3) mm, are subjected to the following electropolishing treatment. The coating electropolishing in under-mentioned (b) and (c) is done so as to impregnate the felt or medical-resistant cloth with the electrolytic solution and pass the current between the work-piece and the cathode sandwiching the felt (cloth) between them. The treatments applying the present invention using the electrolytic case (having the distance between the work-piece and the cathode is 10 mm) are done fo...

embodiment 2

[0078]

[0079]The normal solution and the high-viscous solution are the same as the electrolytic solutions (1) and (2) in the above Embodiment 1.

[0080]

[0081]The treatments are almost same as Embodiment 1, but the voltage is set for large value in the under-mentioned (c) and (d) that correspond to the present invention. Accordingly the current increases, too. In addition, the processing time in (c) and (e) is set for three minutes.

[0082](a) The buffing only.

[0083](b) The coating electropolishing (1 minute) using the normal solution (the electrolytic solution (1)), 11V of voltage, 0.1 A / dm2 of current.

[0084](c) The coating electropolishing (3 minutes) using the normal solution (the electrolytic solution (1)), 11V of voltage, 0.1 A / dm2 of current.

[0085](d) The coating electropolishing (1 minute) using the high-viscous solution (the electrolytic solution (2)), 20V of voltage, 50 to 70 A / dm2 of current.

[0086](e) The coating electropolishing (3 minute) using the high-viscous solution (the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com