Processing biomass

a technology of biomass and enzymes, applied in the field of processing enzymes, can solve the problems of low yield of naturally occurring cellulosic materials, low yield of complex matrix, and high cost of natural-occurring cellulosic materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

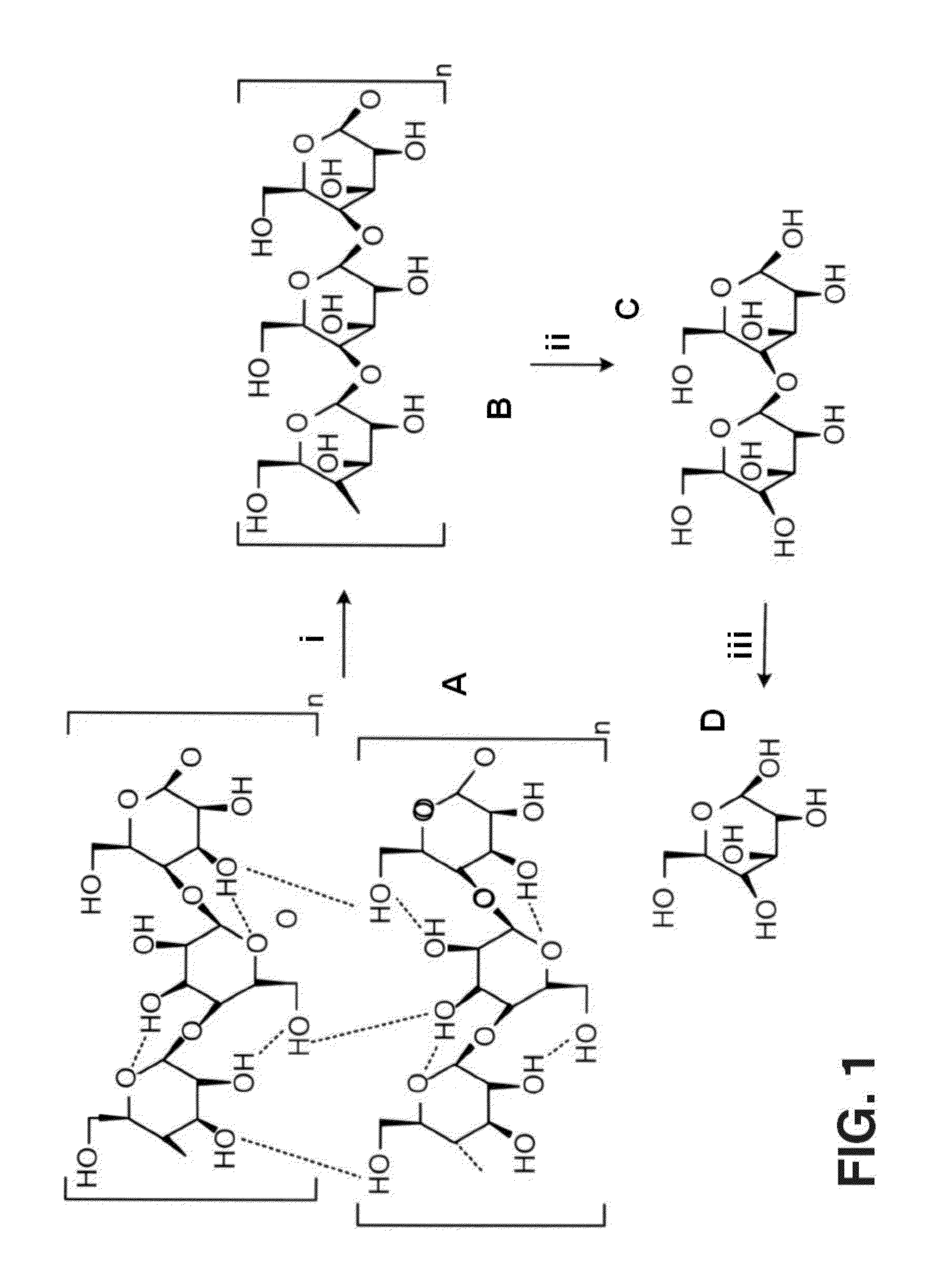

Image

Examples

example 1

Cellulase Performance Test on Paper, Treated Corn Cob and Untreated Corn Cob

[0151]Various inducers (treated biomass (TBM), untreated biomass (UBM), paper (P) and carboxylmethylcellulose (CMC, Aldrich) ) were used to produce enzymes. The biomass (TBM and UBM) was milled corn cob collected between mesh sizes of 15 and 40. Treatment of the biomass (UBM) to produce the TBM involved electron bombardment with an electron beam to a total dose of 35 Mrad. The paper was shredded and screened to have a nominal particle size smaller than 0.16 inch. The inducer experiments were conducted using shake flasks and PC3-7 and RUT-C30 strains. After 3 days of the growth culture, the harvested cell mass was added to a series of shake flasks each containing 50 ml of medium and 1 wt. % of one of the inducers.

[0152]The induction experiment was allowed to proceed for 11 days. The culture supernatant was then harvested by centrifugation at 14,500 rpm for 5 minutes, and stored at 4° C.

[0153]Protein concentra...

example 2

Enzyme Production in Different Concentrations of TBM Inducer

[0156]This Example was done using bioreactors. Cell strain RUT-C30 was propagated in the media with 2.5% glucose. After 3 days of growth the culture was centrifuged and the cells were re-suspended in 50 ml of media with 1, 3, 5, 7 and 9 wt. % TBM. The protein concentrations and activities after 11 days of incubation at 27° C. and 200 rpm are shown in the table below.

TABLE 2Amounts of Protein and Enzyme MadeWith Differing Amounts of InducerInducer amountProteinFPUCMC(wt. %)(g / L)(U / mL)(U / mL)10.71.41.321.43.11.753.46.22.672.92.51.591.50.61.0

[0157]These results show that higher levels of enzymes were produced when the treated biomass (TBM) was added at a rate of 5%.

[0158]Saccharification of biomass with enzymes: Saccharification of biomass (TBM) using enzymes produced by addition of 2, 5 and 7 wt. % treated biomass inducer (TBM) versus a commercial enzyme (Duet™ Accellerase, Genencor) was conducted. The biomass, 10 wt. % TBM, w...

example 3

SDS-PAGE of Enzyme Produced With Treated Biomass

[0159]A bioreactor culture was prepared using the method described above except that the mixing was done at 50 rpm rather than 500 rpm. The protein assay showed that 3.4 g / L protein was produced.

[0160]The analysis of the protein using SDS PAGE is shown in FIG. 5. Lane 1 and 5 are molecular weight markers, Lane 2 is a 30 uL load of the protein, Lane 3 is a 40 uL load of the protein, Lane 4 is Duet™ Accelerase enzyme complex (Genencor).

Example 4. Range of Conditions TestedParametersRangeWorkingBestInductionTestedTestedRangeRangeCorn CobParticle Size1400-1400-Amount Added25-133 g / L25-133 g / L100 g / LTiming ofDay 0-31-3Day 1-3AdditionFrequency of1, 2, and 51, 2, and 51AdditionPresentationwet or drywet or drywet or dryTreatment Levels353535LactoseTiming ofDay 3Day 3Day 3AdditionAmount Added4.7-40 g / L / d4.7-18.7 g / L / d18.7 g / L / dFrequency ofcontinuouscontinuouscontinuousAdditionfeedfeedfeed

[0161]Any patent, publication, or other disclosure materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com