Chemical mechanical polishing aqueous dispersion and chemical mechanical polishing method for semiconductor device

a chemical mechanical and semiconductor technology, applied in lapping machines, other chemical processes, manufacturing tools, etc., can solve the problems of incomplete copper removal, large friction, and large reduction of polishing rate, so as to reduce copper dishing and copper corrosion, reduce friction during polishing, and high affinity to copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first specific example

2.1 First Specific Example

2.1.1 Polishing Target

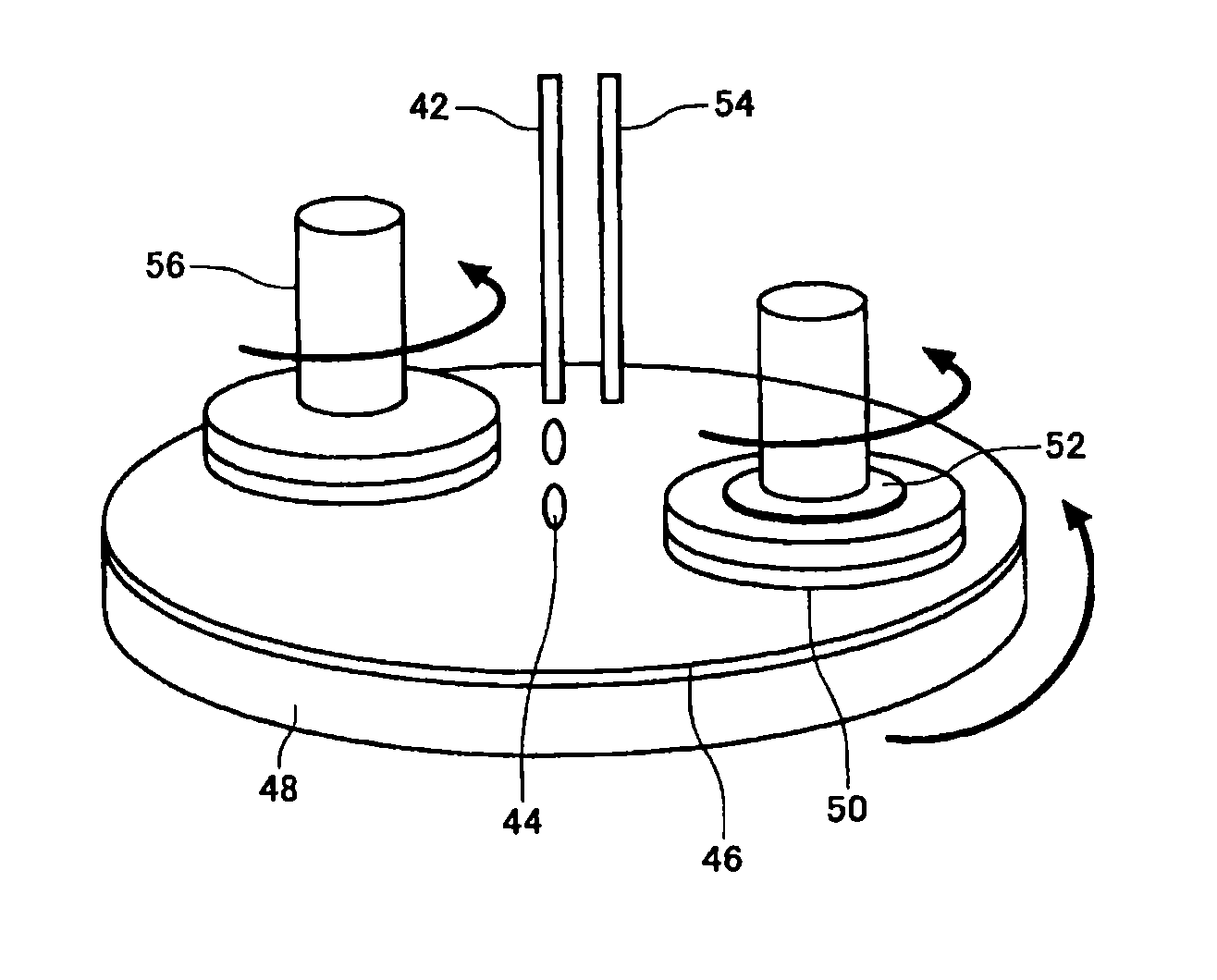

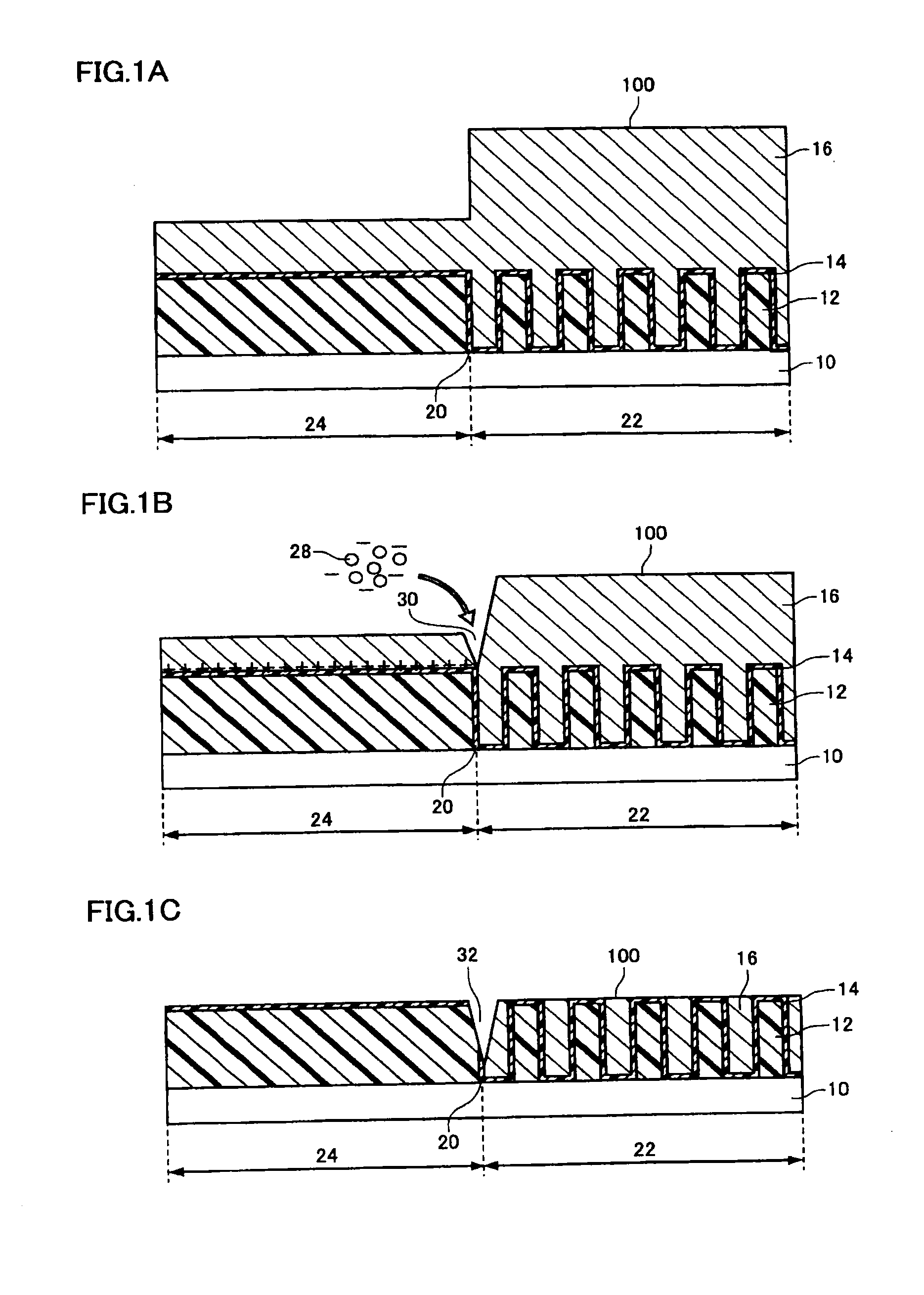

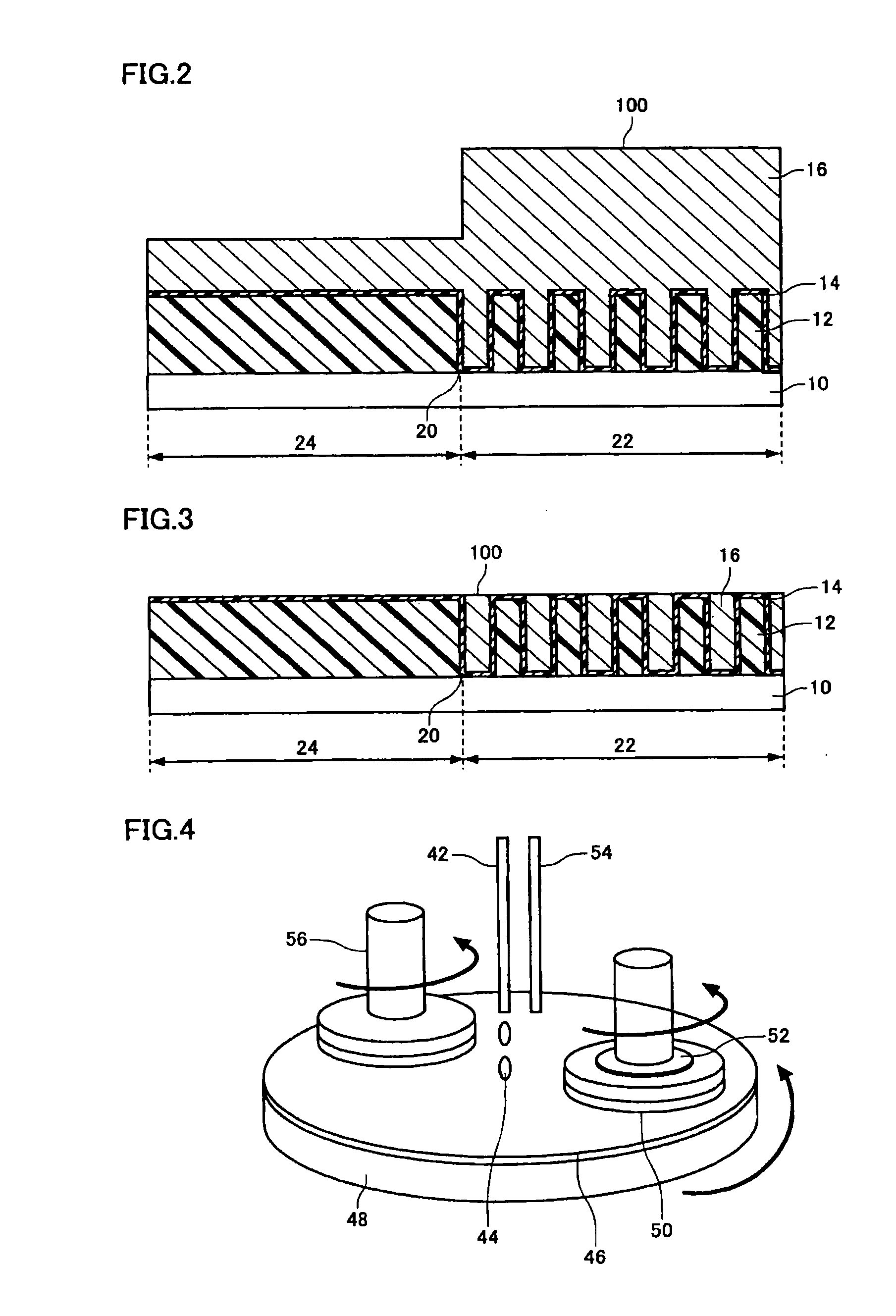

[0101]FIG. 2 shows a polishing target 100 of the chemical mechanical polishing method according to a first specific example. FIG. 2 shows a polishing target which is the same as that shown in FIG. 1A. The material for each layer and the like are also described below.

[0102]An insulating layer 12 formed of silicon oxide is provided on a substrate 10 on which semiconductor elements (not shown) are formed. An interconnect depression 20 is formed by etching the insulating layer 12. The insulating layer 12 may be a PETEOS layer, an insulating layer having a relative dielectric constant of 3.5 or less, or the like. The insulating layer 12 is preferably an insulating layer having a relative dielectric constant of 3.5 or less, and more preferably 3.0 or less.

[0103]A barrier layer 14 is formed to cover the surface of the insulating layer 12 and the bottom and the inner wall surface of the interconnect depression 20. The barrier layer 14 may be f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight average molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com