Coating/repairing process using electrospark with psp rod

a technology of electrospark and electrospark, which is applied in the direction of stators, machines/engines, mechanical apparatuses, etc., can solve the problems of reducing the efficiency of a jet turbine, affecting certain desired characteristics of the substrate-containing component, and creating surface imperfections on die-cast parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

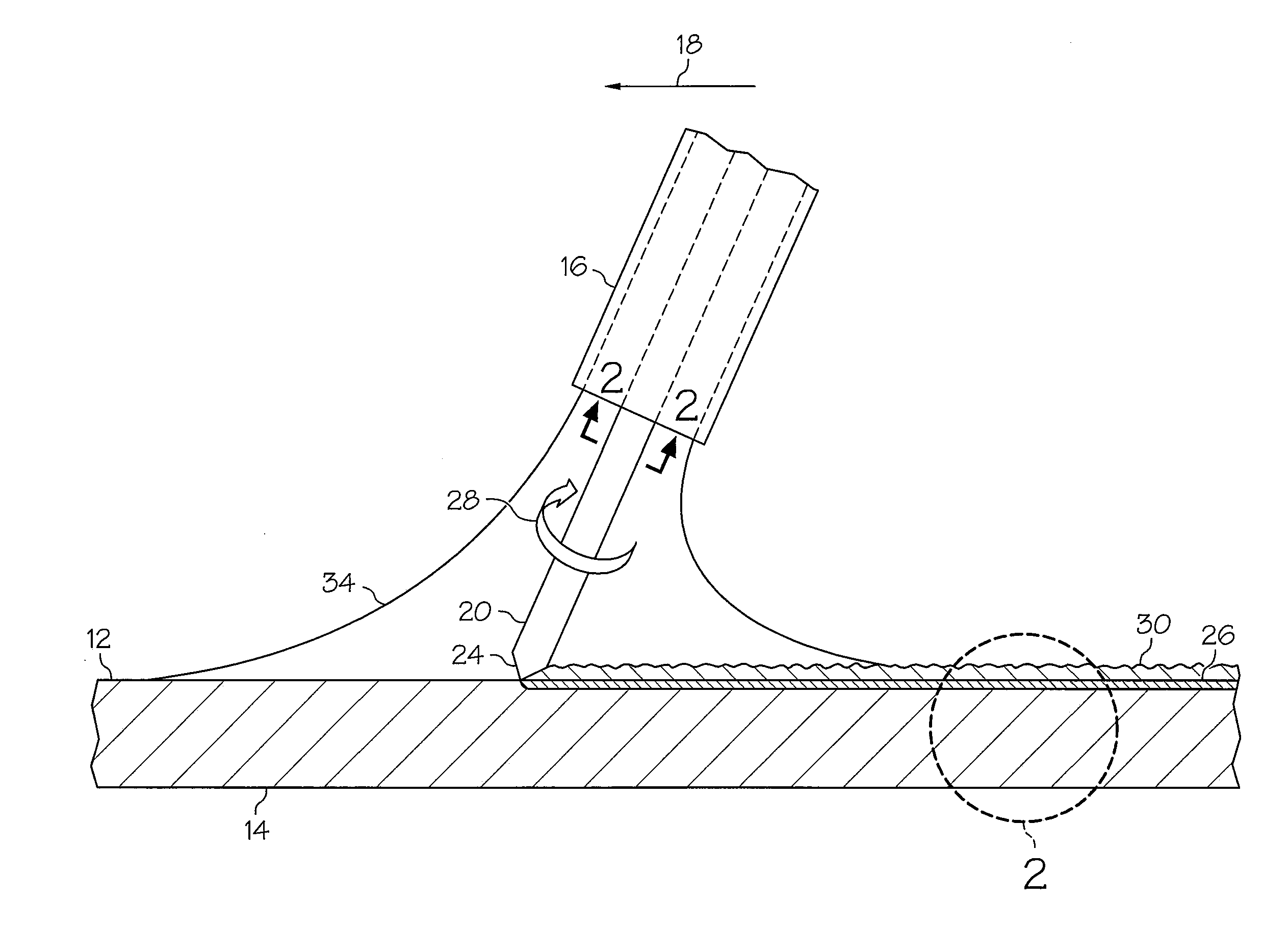

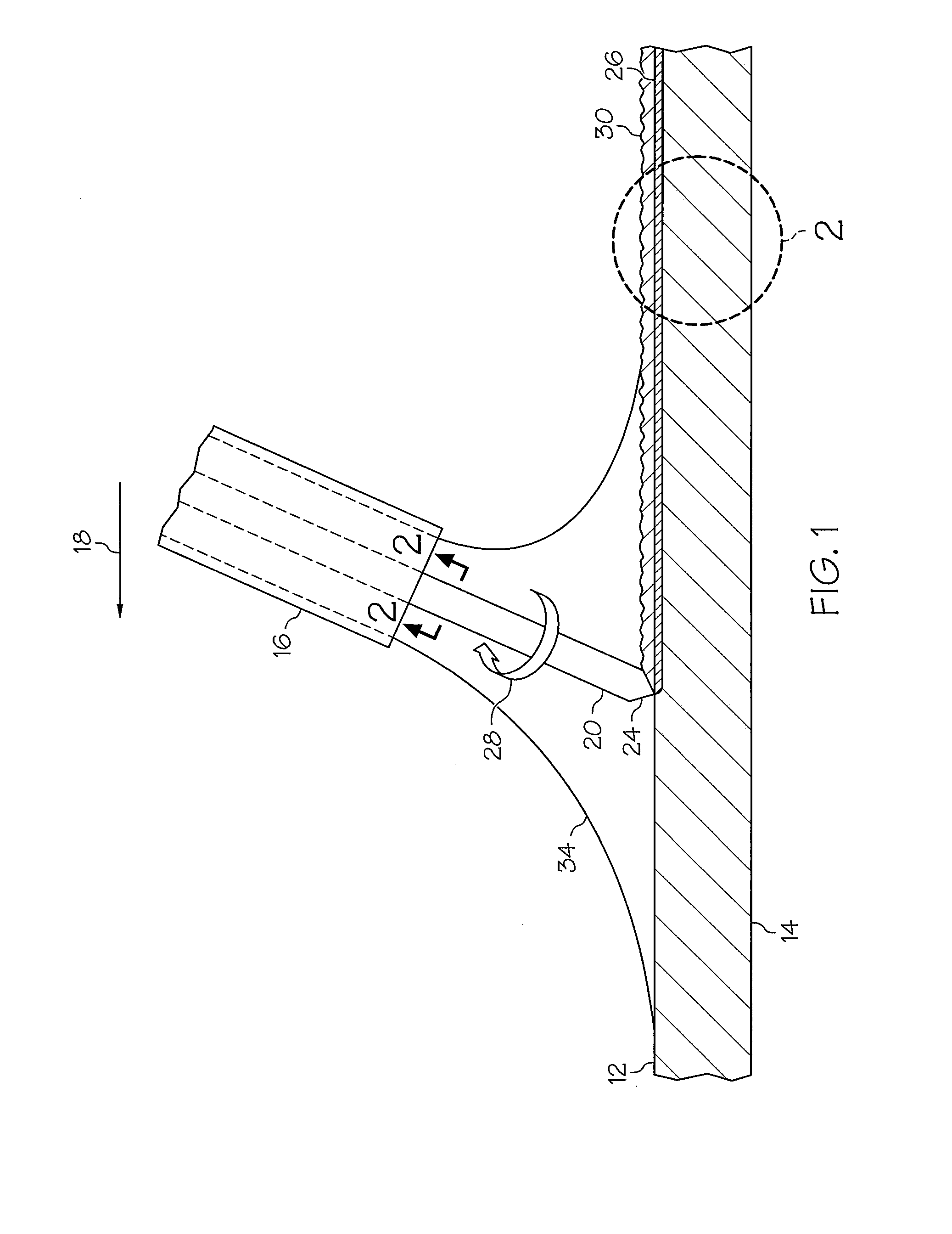

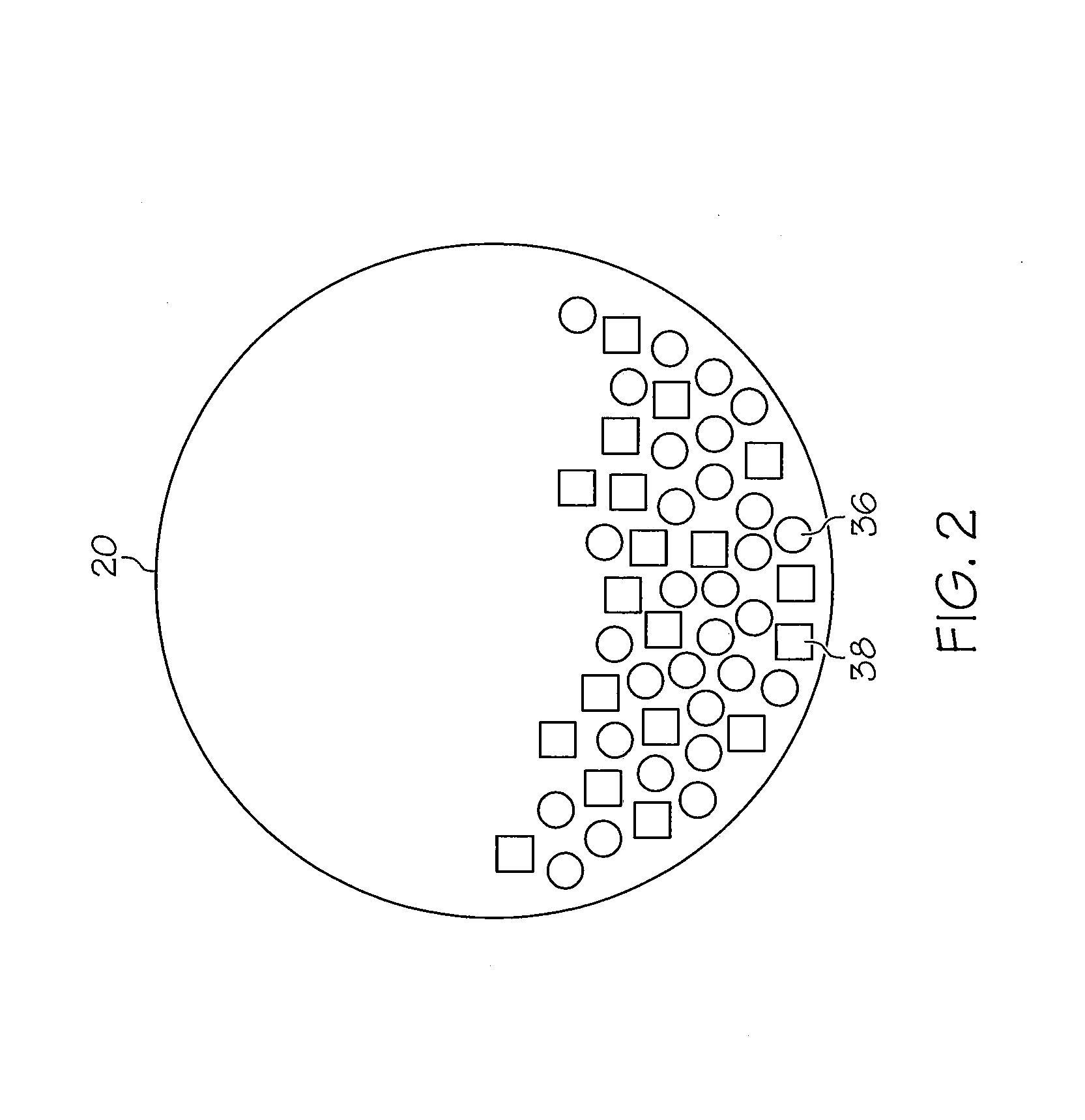

[0014]Example embodiments that incorporate one or more aspects of the invention are described and illustrated in the drawings. These illustrated examples are not intended to be a limitation on the invention. For example, one or more aspects of the invention can be utilized in other embodiments and even other types of devices. Moreover, certain terminology is used herein for convenience only and is not to be taken as a limitation on the invention. Still further, in the drawings, the same reference numerals are employed for designating the same elements.

[0015]Coating and repairing operations utilizing ESD can be beneficial when compared to other metal deposition processes used in die manufacturing or turbine component repair. The ESD process tends to minimize the heat affected zone (HAZ) of the substrate. The HAZ can be defined as a volume of the substrate where the microstructure and properties of the substrate have been altered by the ESD process. Minimizing the HAZ can be beneficia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Ra | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com