Multilayer Thermoformable Materials and Sanitary Food Containers Made Therefrom

a thermoformable material and multi-layer technology, applied in the field of multi-polymer-layer thermoformable materials and articles, can solve the problems of excessive thickness of preformed liners, time-consuming and messy cleaning of rollers and trays after use, and increase environmental waste upon disposal, so as to prevent contamination and physical damage, easy peeled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

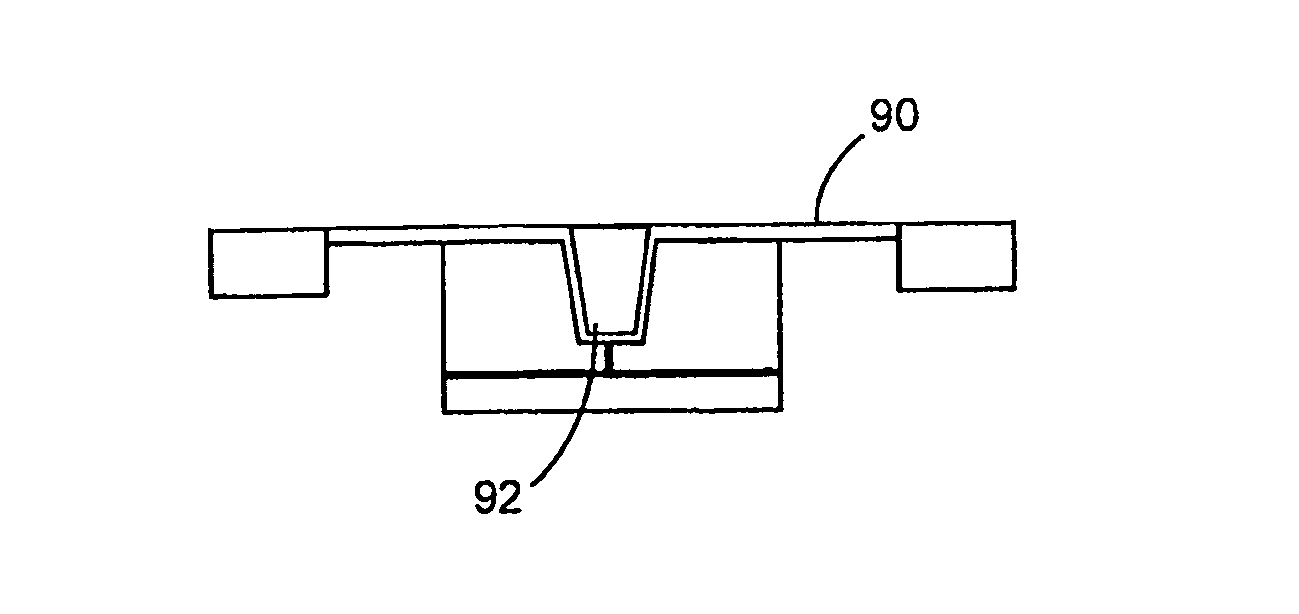

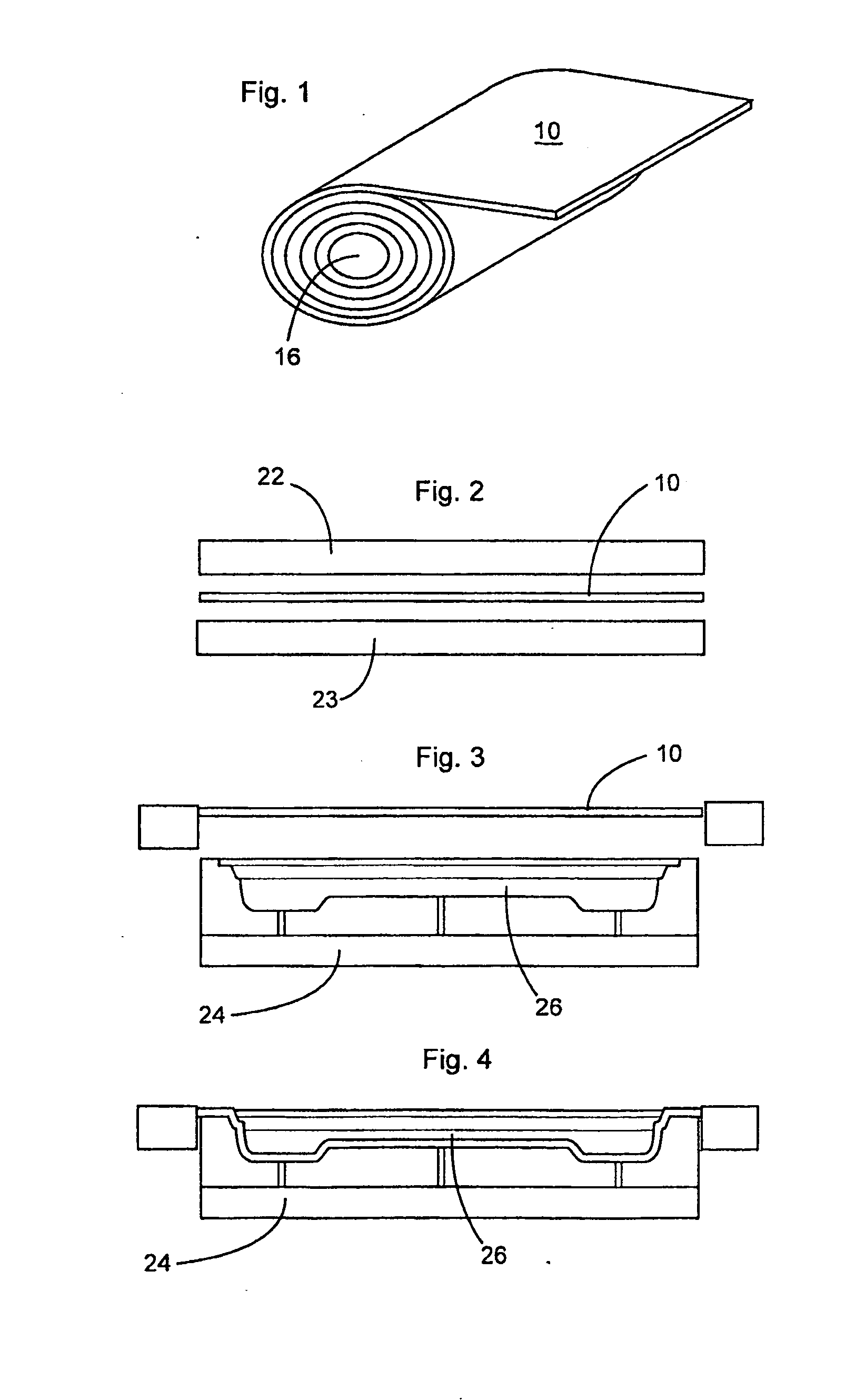

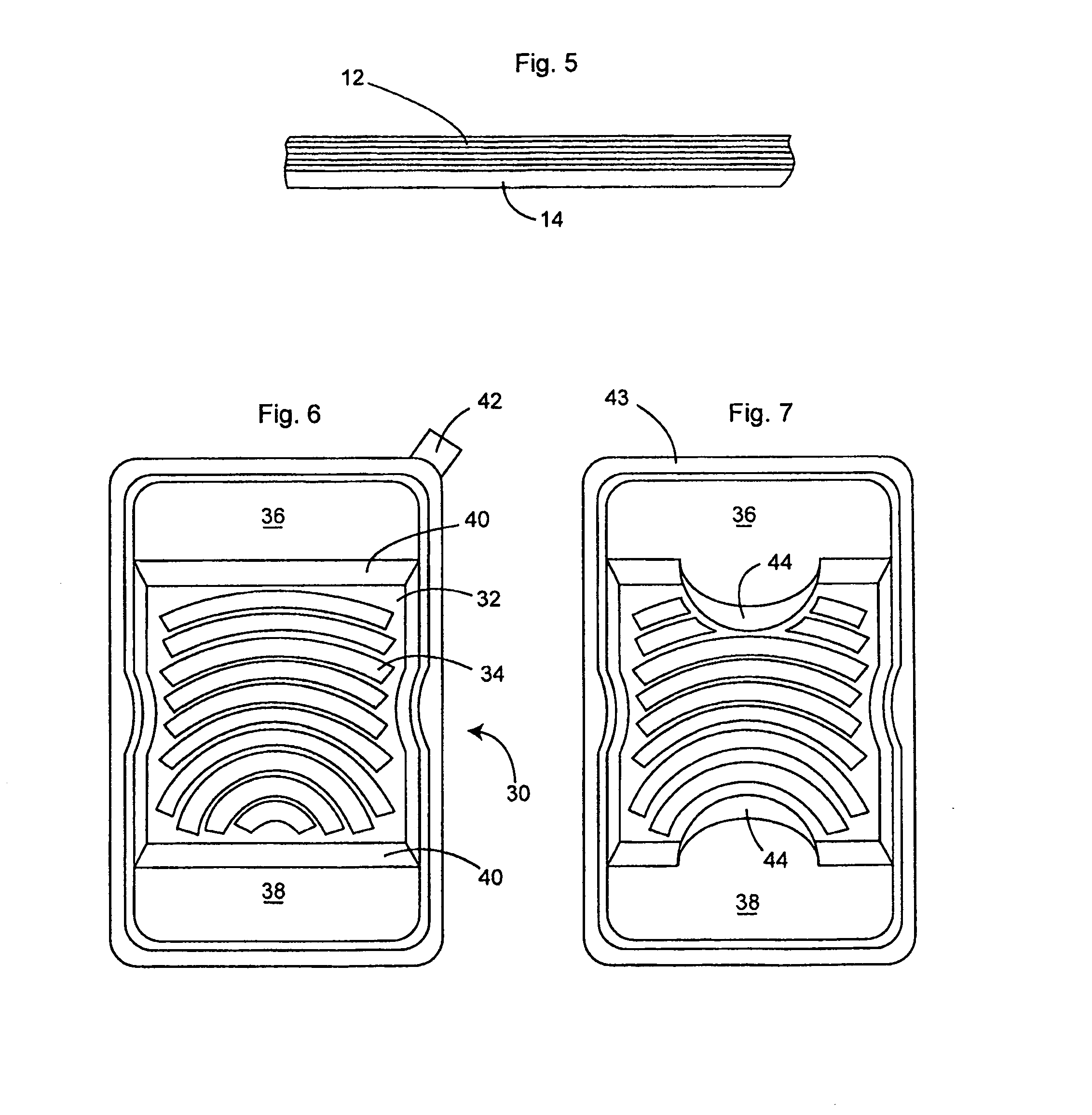

[0168]A food service container designed to be inserted into a rack for holding multiple food service containers as a part of a sandwich assembly station was fabricated. The concave interior portion of the container had the approximate conformation of a tapered rectangular cuboid having rounded edges and dimensions of about 10½ inch length (tapering to about 11¾ inch at the opening)×about 4¾ inch width (tapering to about 5¾ inch at the opening)×5½ inch depth. The corners of the interior cuboid had radii of about ⅞ inch. A flange extended about the opening, having a length of about 12¾ inches and a width of about 6⅞ inches, with rounded corners (about ¾ inch radius).

[0169]In this embodiment, the rigid sheet was composed of PET (polyethylene terephthalate), black in color, approximately 30 mils (i.e., ca. 0.03 inch) in thickness. The container included ten second sheets peelably adhered to the rigid sheet. Each of the second sheets was composed of polyethylene, was white in color, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com