Mold having ceramic insert

a technology of ceramic inserts and molds, applied in the field of molds, can solve the problems of mold wear, unsatisfactory need for electrode molds, long service life, etc., and achieve the effects of reducing material loss, increasing the yield of molding process, and prolonging service li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

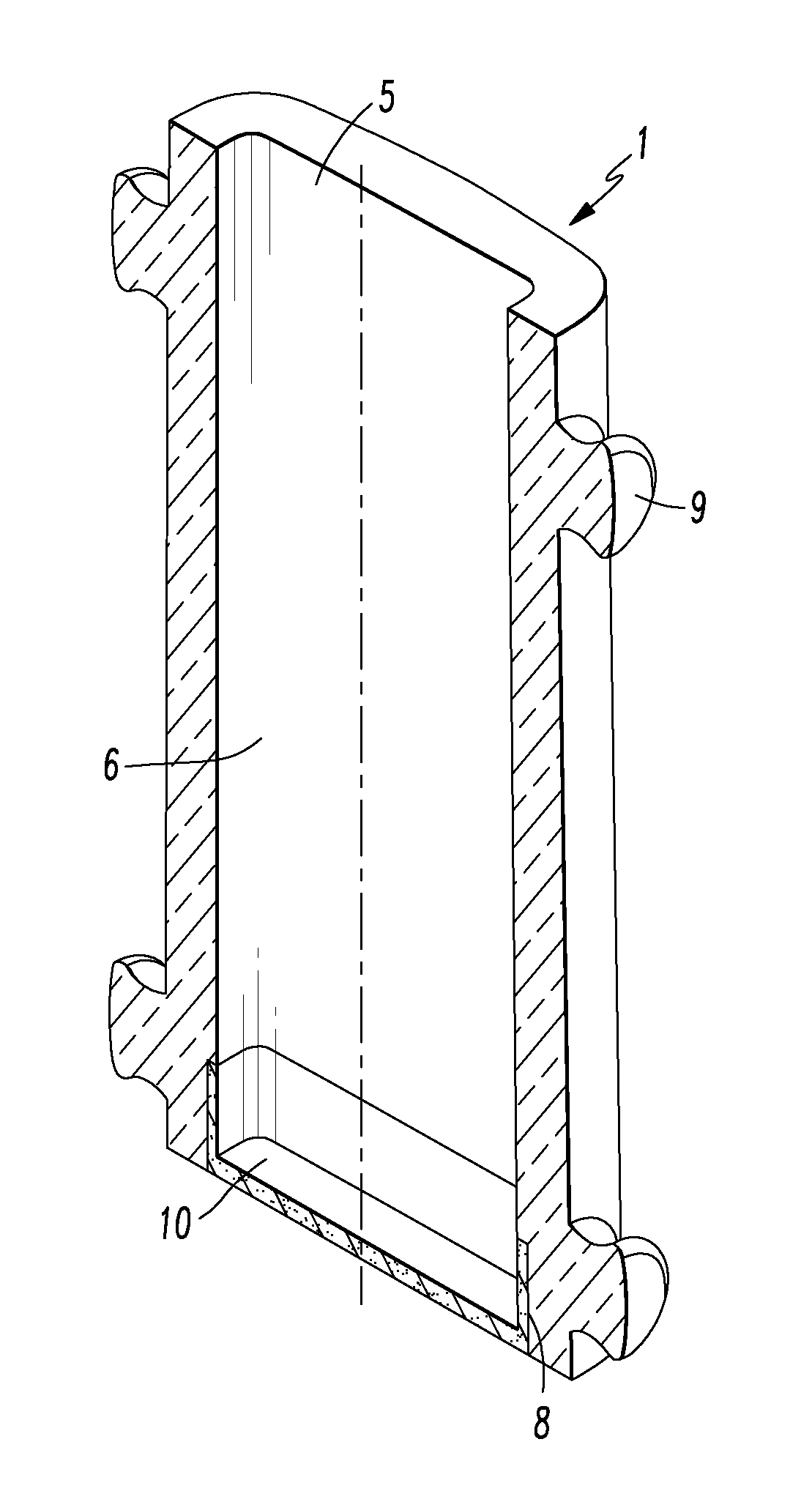

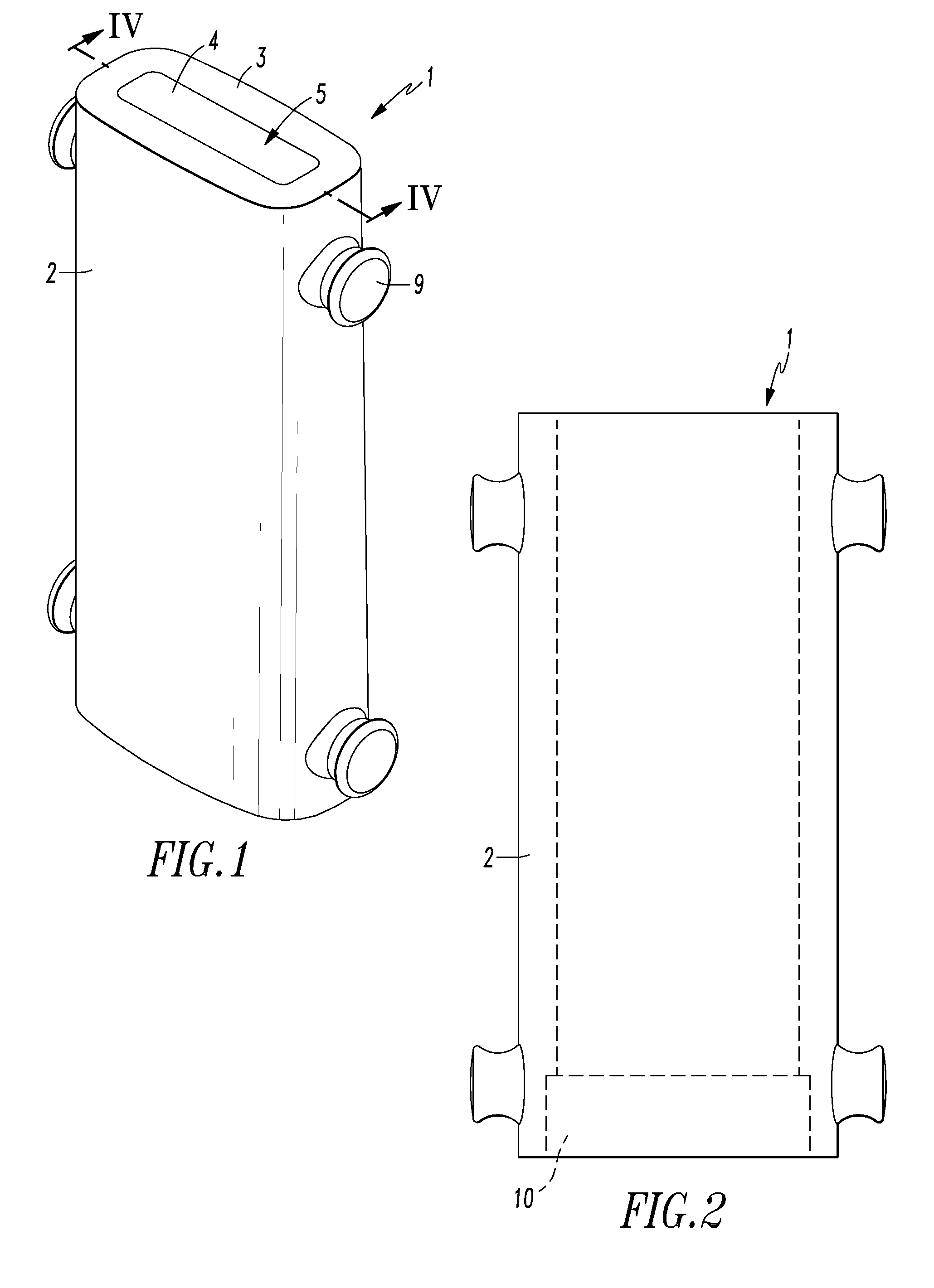

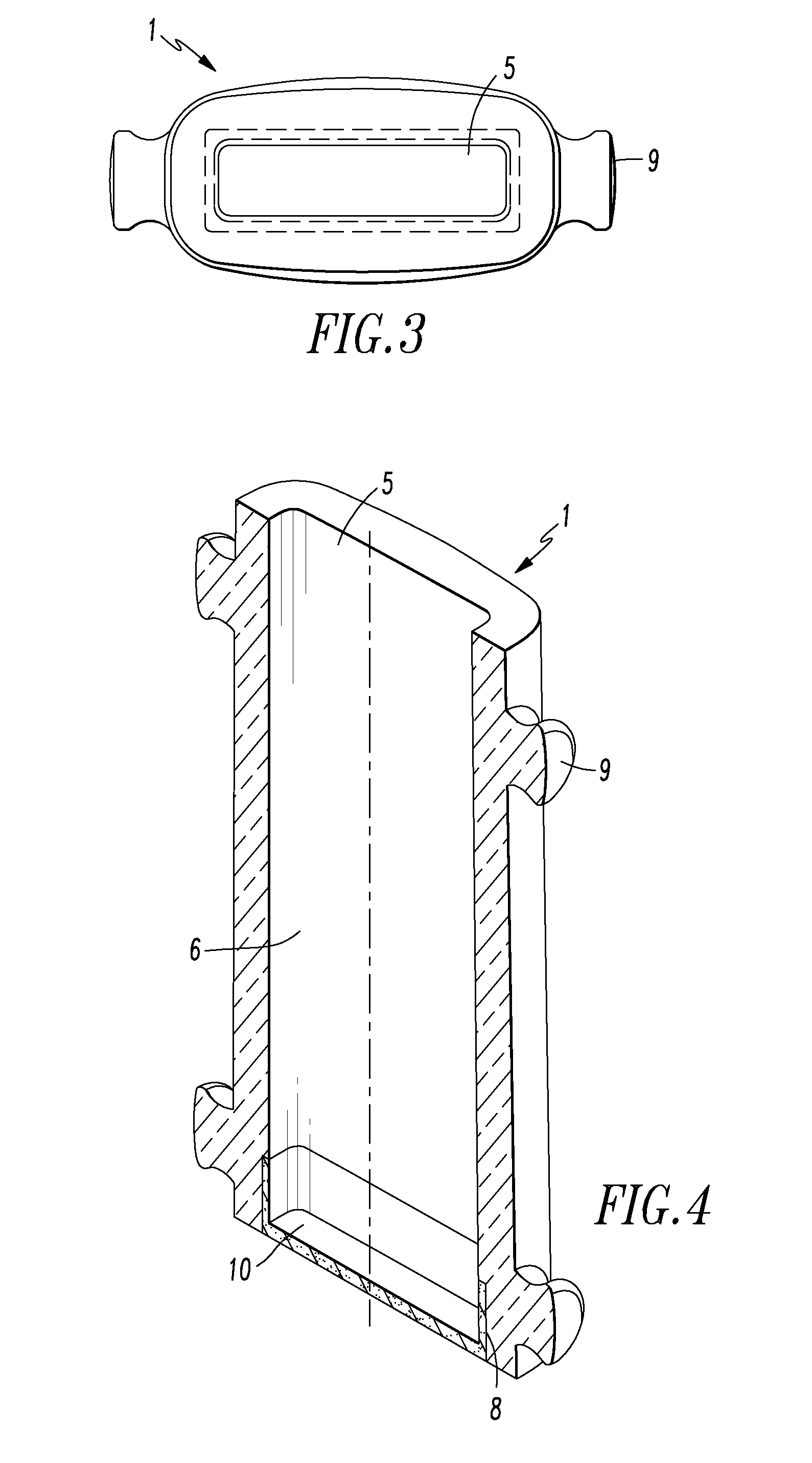

[0024]Referring to FIGS. 1 through 4 I provide an improved mold 1 for casting ingots, electrodes and other metal parts that has a tubular body 2 with an opening 4 in the top 3 of the mold. Handles or lugs 9 are provided on the mold which allowed the mold to be lifted by an overhead crane using hooks that grab the handles. As can be seen most clearly in FIG. 4, I provide a ceramic insert 10 that fits into the bottom of the mold closing off the mold cavity 5. A recess 8 is provided in the cavity wall 6 at the bottom of the mold 1. The recess is sized to receive the side walls 12 and end walls 13 of the ceramic insert 10 shown in FIGS. 5 through 8. A bonding material is applied to the ceramic insert before it is placed within the recess to hold the ceramic insert in the mold. A bonding material sold under the trade name Ladle Lock by Reico Products, Inc. is suitable for this purpose. The binding material is applied to at least a portion of the sidewalls of the ceramic insert before the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com