Implant deployment apparatus

a technology for deploying equipment and implants, applied in the field of implants, can solve the problems of high incidence of repeat intervention, long recovery time after surgery, morbidity and mortality,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

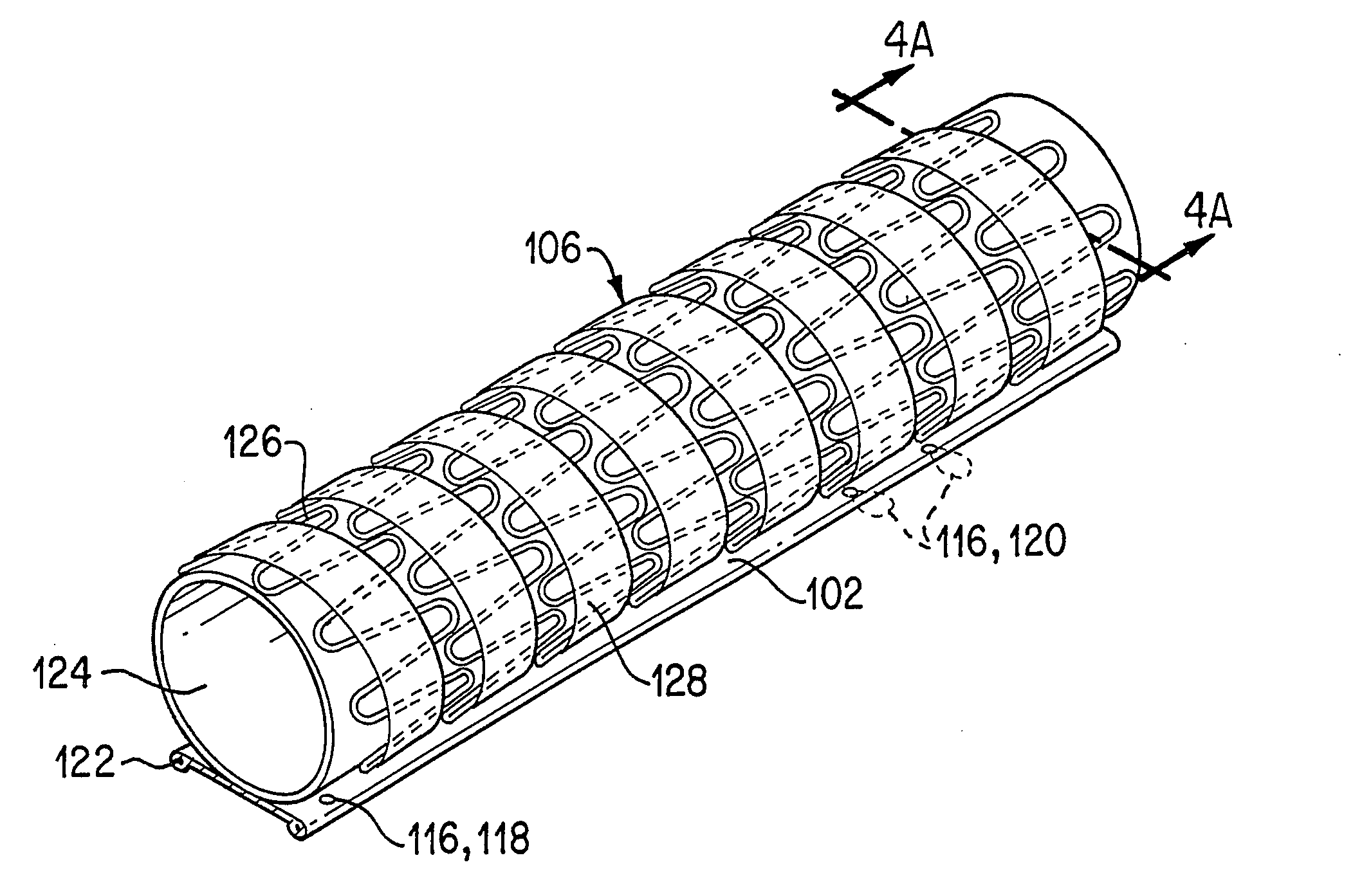

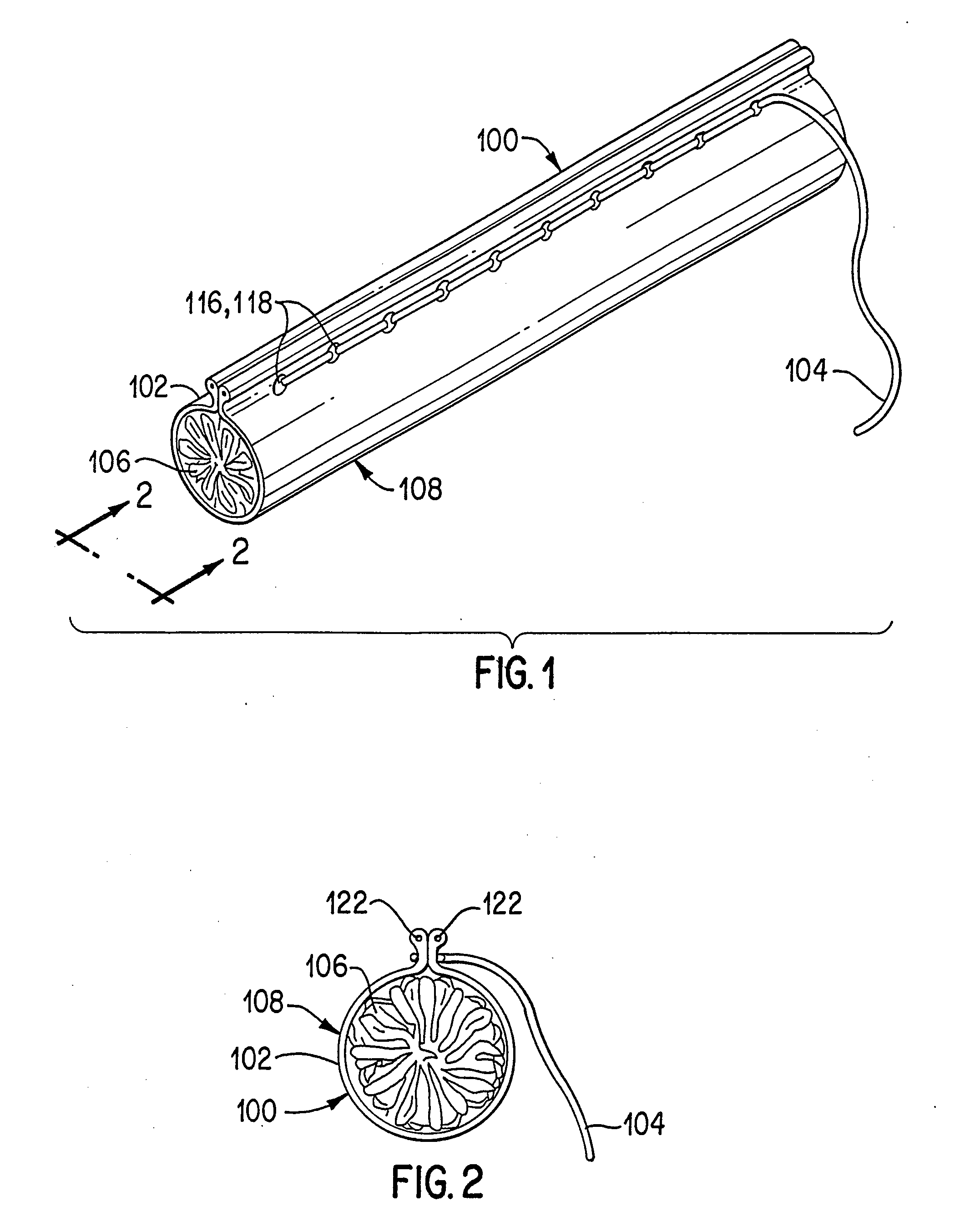

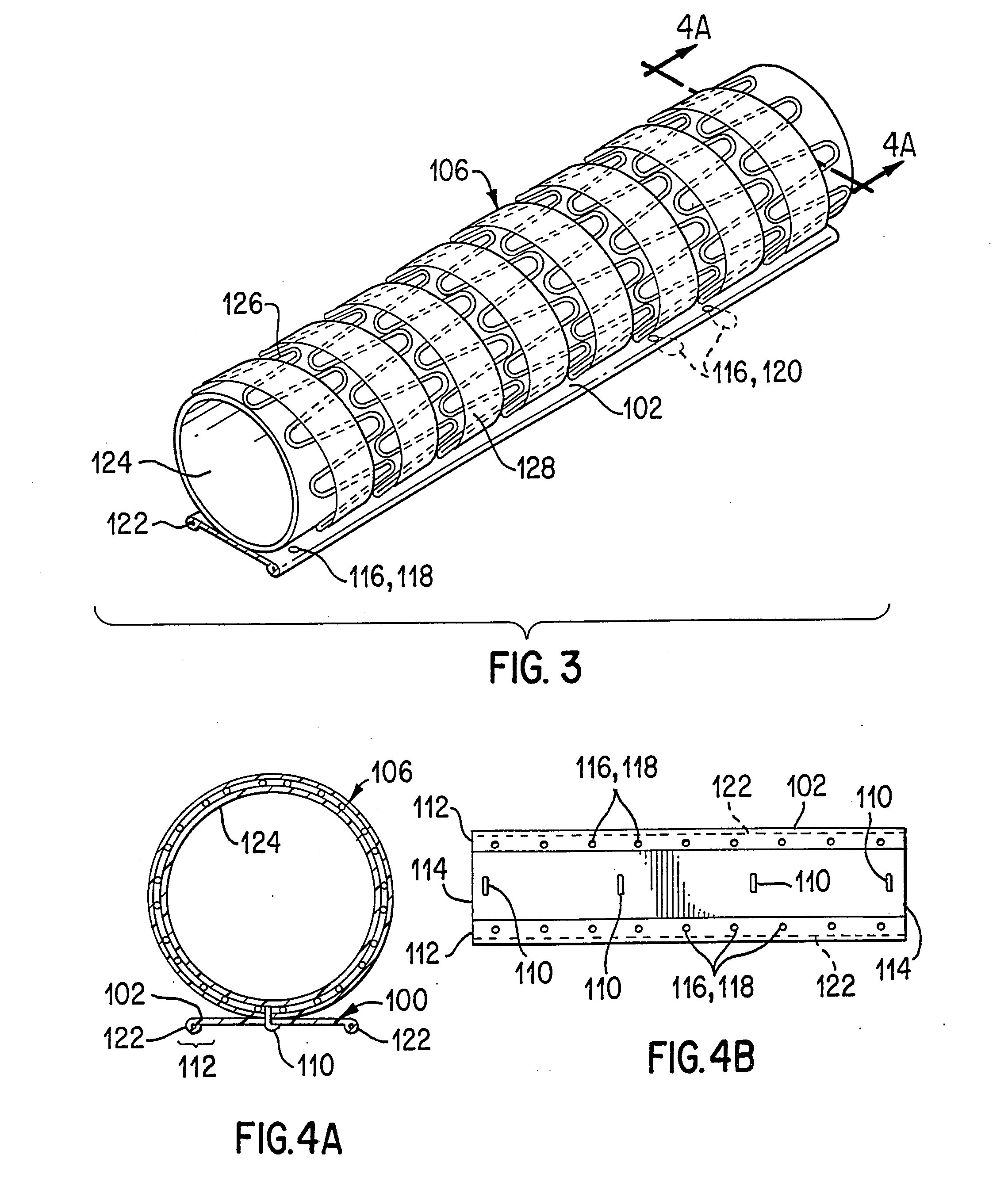

[0069]Referring to the drawings in detail wherein like numerals indicate like elements, delivery systems for delivering implants or devices, such as stents or stent-grafts, to a desired site in mammalian vasculature are shown in accordance with the principles of the present invention. The delivery systems of the present invention generally include a restraining member that is adapted and configured for surrounding at least a portion of a collapsed or compressed implant and a coupling member(s) for releasably coupling portions of the restraining member to one another to maintain the implant in its collapsed or compressed state.

[0070]Referring to FIGS. 1-4, an implant delivery system constructed in accordance with the present invention is shown. Delivery system (100), generally includes a restraining member (102), which as shown may be in the form of a sheet of material, and a coupling member (104) for releasably coupling portions of the restraining member to one another. The restrain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com