Magnetic field detector based on perpendicular exchange coupling and preparing and use methods thereof

A vertical exchange coupling and detector technology, applied in the direction of the magnitude/direction of the magnetic field, devices using electro-magnetic effects, and the manufacture/processing of electromagnetic devices, which can solve the problem of weakening output signals, increasing noise, and signal instability, etc. problem, to achieve the effect of flat adhesion, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention is based on the preparation method of the magnetic field detector of vertical exchange coupling, specifically comprises the following steps:

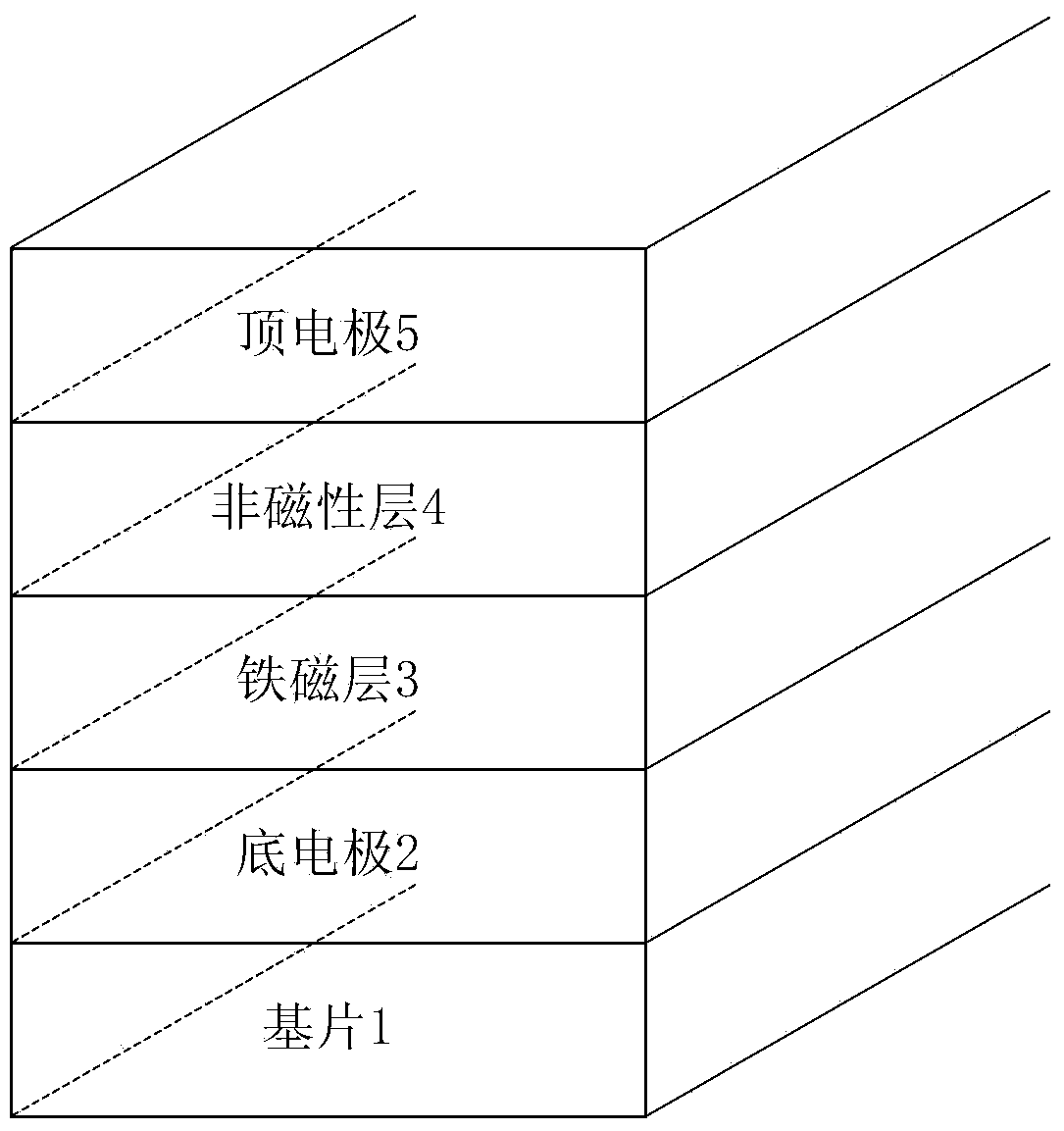

[0025] 1) The bottom electrode 2, the ferromagnetic layer 3, the non-magnetic layer 4 and the top electrode 5 are sequentially deposited on the substrate 1 by magnetron sputtering or electron beam evaporation to obtain a multilayer film structure.

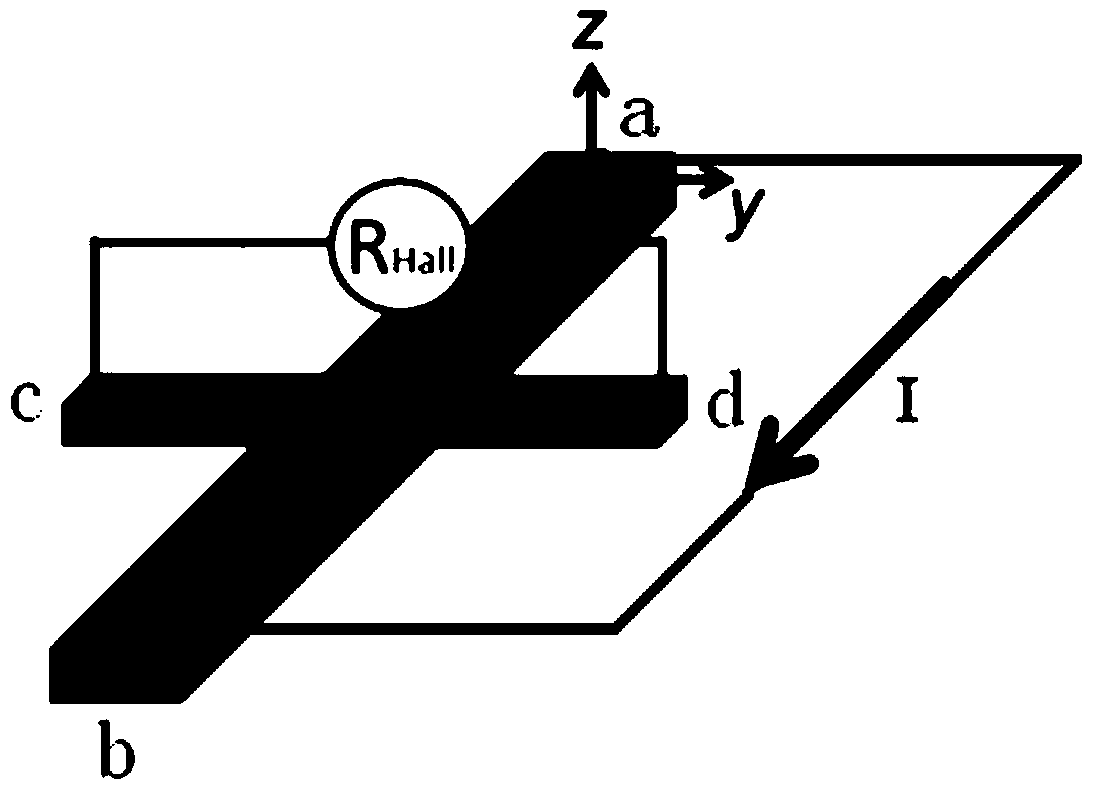

[0026] 2) if figure 2 As shown, the multilayer film structure obtained in step 1) is processed into a cross-shaped structure by using processes such as ultraviolet exposure and argon ion etching. The area of the rectangle where the cross-shaped structure is located is 500×300 μm 2 ~1000×600μm 2 , the area of the cross-overlapped part in the center of the cross-shaped structure is 5×3 μm 2 ~40×30μm 2 .

[0027] Such as figure 2 As shown, the first to fourth endpoints of the magnetic field detector based on the vertical exchange coupling of the present i...

Embodiment 1

[0048] Example 1: Preparation of Si / SiO from bottom to top 2 / [Pt / Co] 2 / IrMn / Pt magnetic field detector, which specifically includes:

[0049] 1) Using magnetron sputtering method, on Si / SiO 2 On the substrate 1, the Pt bottom electrode 2, [Pt / Co] 2 The ferromagnetic layer 3, the IrMn non-magnetic layer 4 and the Pt top electrode 5 form a multilayer film structure.

[0050] Among them, Si / SiO 2 SiO in substrate 1 2 The thickness of the layer is 200 to 400 nm. [Pt / Co] 2 In the ferromagnetic layer 2, the thickness of the Pt layer was 1 nm, and the thickness of the Co layer was 0.5 nm. The thickness of the IrMn nonmagnetic layer 3 is 6 nm to 20 nm, preferably 8 nm.

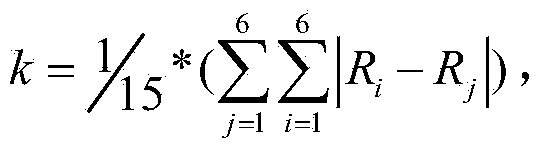

[0051] 2) Process the multilayer film structure into a cross-shaped structure by using ultraviolet exposure and argon ion etching. The area of the rectangle where the cross-shaped structure is located is 500×300 μm 2 ~1000×600μm 2 , the area of the cross-overlapped part in the center of the cross-shape...

Embodiment 2

[0062] Example 2: Preparation of a magnetic field detector of MgO / CoFeB / FeMn / Pt from bottom to top

[0063] 1) Using the method of magnetron sputtering, a Pt bottom electrode 2, a CoFeB ferromagnetic layer 3, a FeMn nonmagnetic layer 4 and a Pt top electrode 5 are sequentially deposited on the MgO substrate 1 to obtain a multilayer film structure.

[0064] Wherein, the CoFeB ferromagnetic layer 3 is a perpendicularly magnetized ferromagnetic layer with a thickness of 0.7-1.5 nm, preferably 1.2 nm. The thickness of the FeMn non-magnetic layer 4 is 6-20 nm, preferably 10 nm.

[0065] 2) Process the multilayer film structure into a cross-shaped structure by using ultraviolet exposure and argon ion etching. The area of the rectangle where the cross-shaped structure is located is 500×300 μm 2 ~1000×600μm 2 , the area of the cross-overlapped part in the center of the cross-shaped structure is 5×3 μm 2 ~40×30μm 2 .

[0066] Such as figure 1 As shown, a current is passed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com