Methods for converting lignocellulosic materials to useful products

a technology of lignocellulosic materials and pretreatment solutions, which is applied in the fields of papermaking, glucose production, biofuels, etc., can solve the problems of low efficiency, environmental protection, and process currently not commercialized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Materials and Methods for Examples 2-13

Bagasse Pretreatment and Sample Analysis

[0082]All bagasse samples in Examples 2-13 were prepared according to the methods described herein with the specific conditions, such as the concentration of the components in the pretreatment solutions and the reaction conditions, provided in the specific Examples 2-13 below.

[0083]Air-dried depithed bagasse was ground and the material retained between 0.25 mm and 0.50 mm sieve was collected. One gram (moisture content of 5%) of the bagasse was mixed with 10 grams of the pretreatment solution, (e.g., water, acid catalyst, and glycerol). When glycerol was present in the pretreatment solution, the purity grade of the glycerol was analytical grade (i.e., commercial glycerol) with a water content less than 0.5%. The mixture was stirred at 300 rpm and heated at the indicated temperature for a set time as set forth in each example. After pretreatment, the mixture was vacuum-filtered to produce a filtrate (i.e.,...

example 2

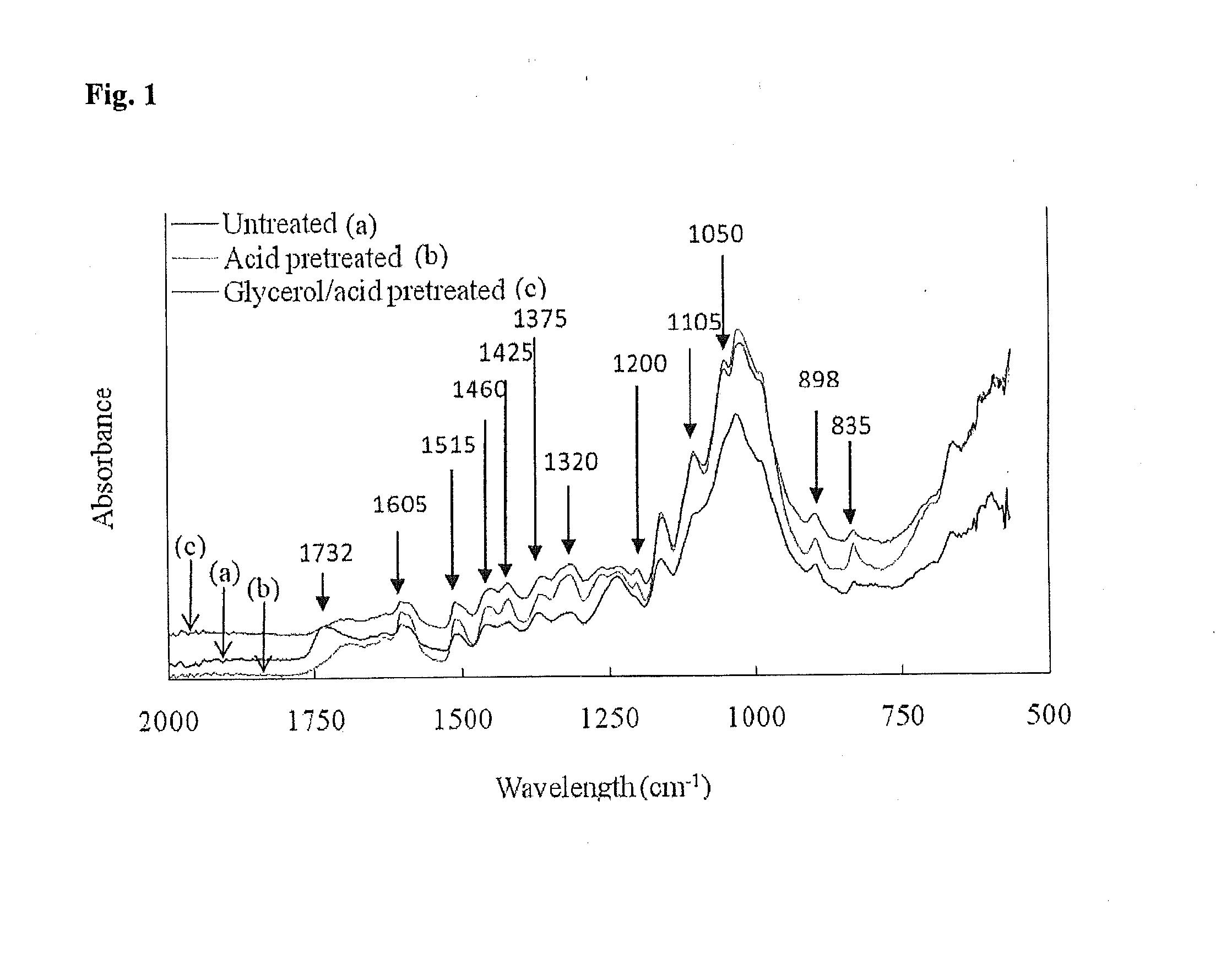

FTIR Data of Untreated Bagasse and Pretreated Bagasse

[0095]FIG. 1 shows FTIR spectra of untreated bagasse and bagasse pretreated with either an acid solution or a glycerol / acid / water solution. The bagasse samples were either untreated or pretreated with the acid solution or the glycerol / acid / water solution for 60 minutes at 130° C. The acid solution contained 1.2% HCl and 98.8% water. The glycerol / acid / water solution contained 1.2% HCl, 88.8% glycerol, and 10% water.

[0096]The ester bond signal at 1732 cm−1 was weaker in the spectrum of the pretreated samples than that of the untreated sample, suggesting that some ester linkages between lignin and the carbohydrates were cleaved during the pretreatment process (Liu et al., 2009).

[0097]The peaks at 1515 cm−1 and 1605 cm−1, which relate to the aromatic skeleton vibrations in lignin (Liu et al., 2009), were present in the pretreated samples, indicating that the pretreatment process did not completely remove lignin. The peaks at 1515 cm−1...

example 3

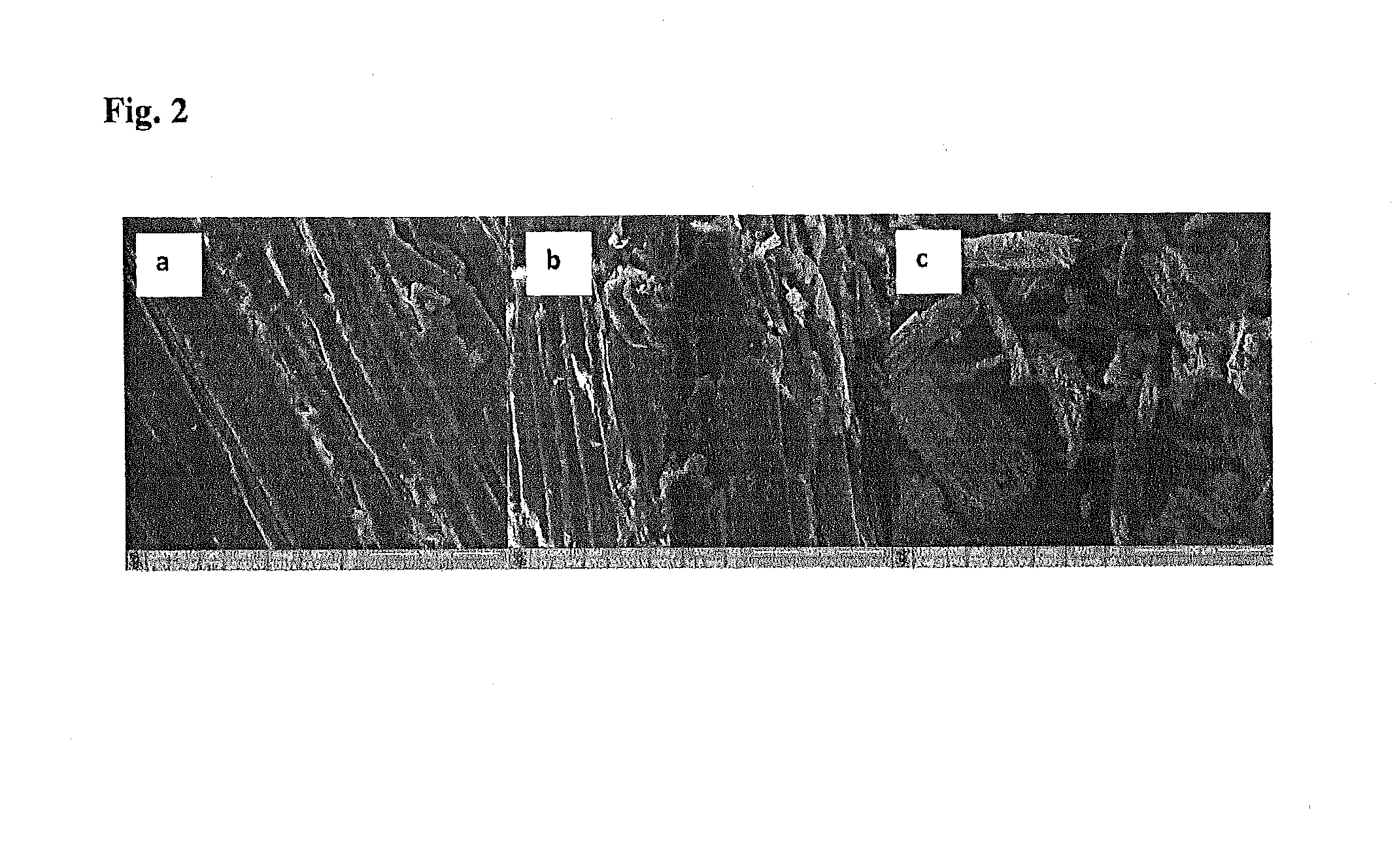

SEM of Untreated Bagasse and Pretreated Bagasse

[0101]Scanning electron microscopy (SEM) analysis was conducted to study changes in bagasse morphology following various pretreatments. The bagasse samples were either untreated or pretreated with an acid solution or a glycerol / acid / water solution for 60 minutes at 130° C. The acid solution contained 1.2% HCl and 98.8% water. The glycerol / acid / water solution contained 1.2% HCl, 88.8% glycerol, and 10% water.

[0102]As shown in FIG. 2, the untreated bagasse sample exhibited grid and compact fibrils (FIG. 2a), which hinder the ability of the enzymes to access the cellulosic and hemicellulosic components of the bagasse (i.e., the lignocellulosic material) during saccharification. The morphology of bagasse pretreated with the acid solution did not change significantly compared to untreated bagasse (FIG. 2b), although some pores appeared in the acid pretreated bagasse. In contrast, pretreatment with the glycerol / acid / water solution destroyed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com