Water-cooled condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

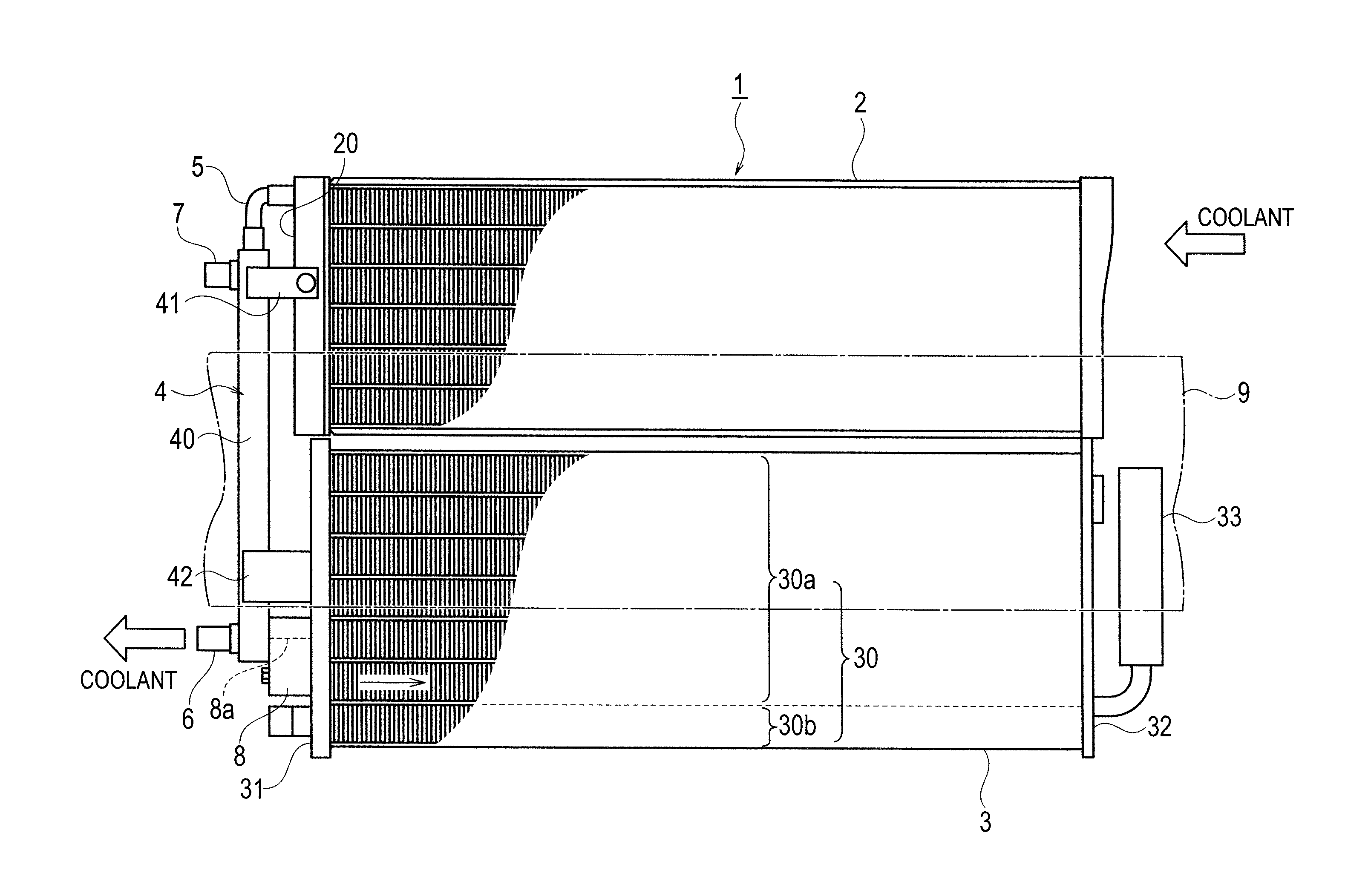

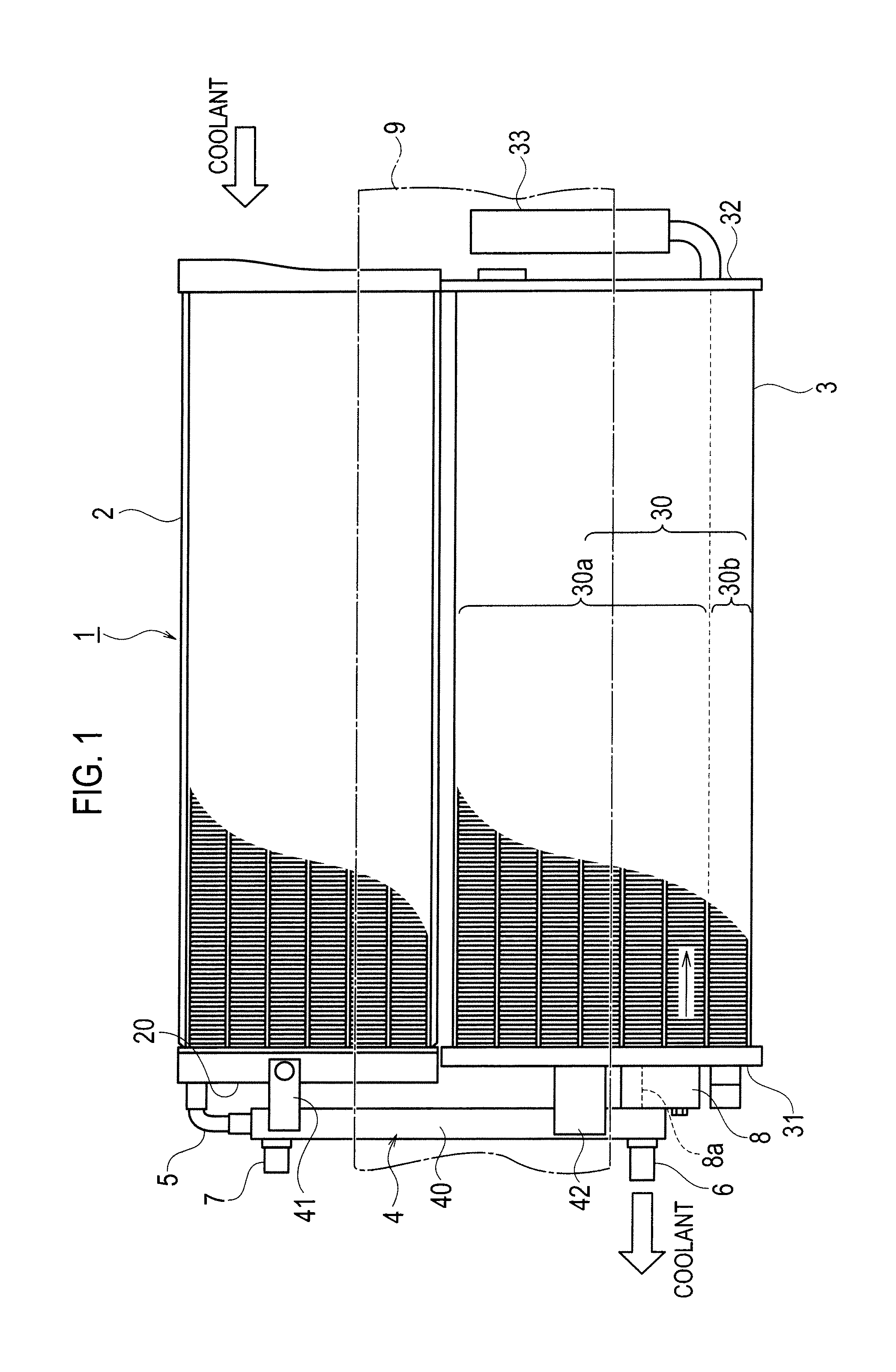

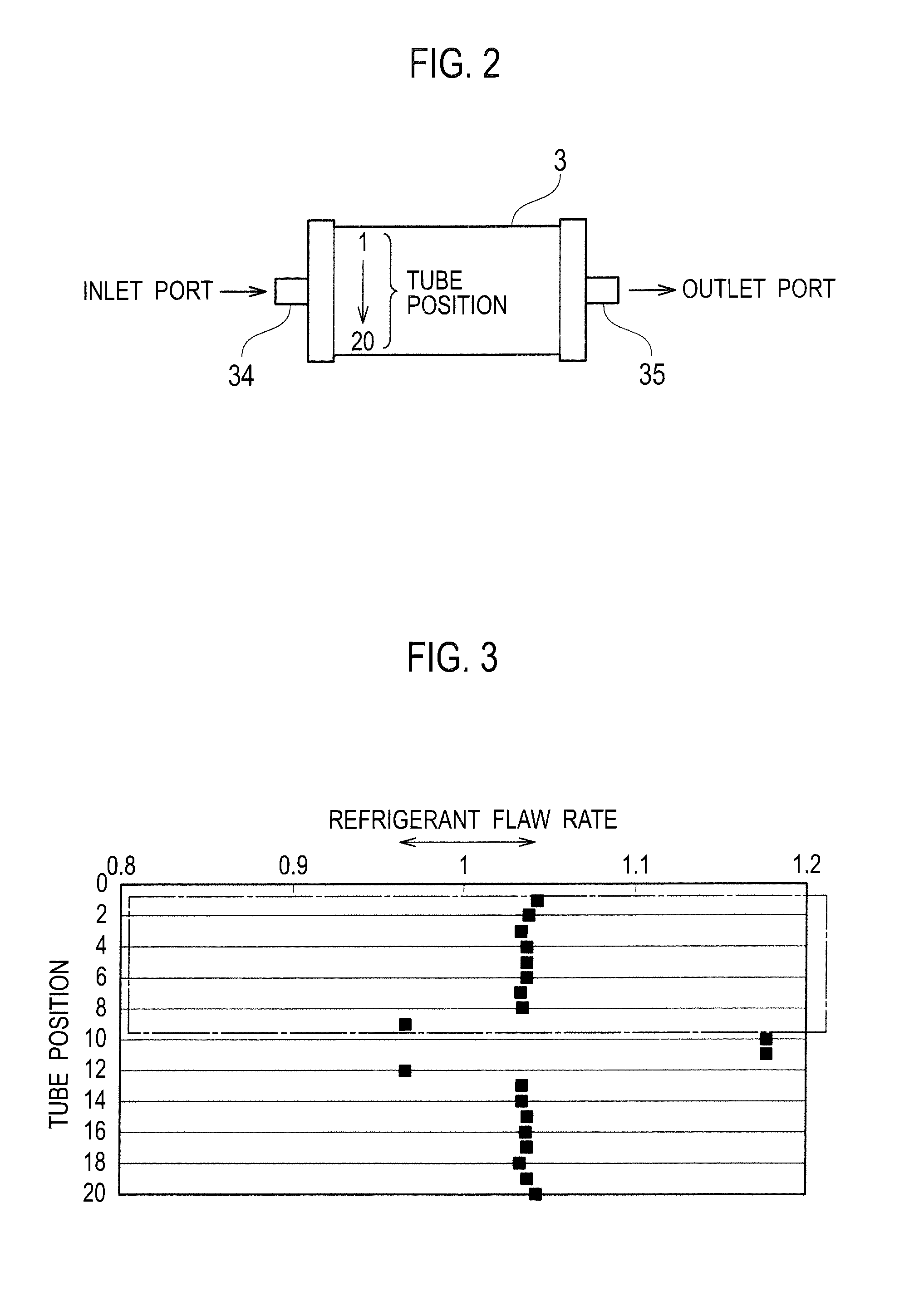

[0022](First Embodiment)

[0023]As shown in FIG. 1, the combined heat exchanger 1 includes a sub-radiator 2, an in-compartment air-cooled condenser 3, and a water-cooled condenser 4. The sub-radiator 2 exchanges heat between coolant for cooling a heat-generating object (e.g. an inverter when a vehicle is an EV or an HEV) and outside air (to reduce temperature of the coolant). The air-cooled condenser 3 is disposed under the sub-radiator 2, and exchanges heat between refrigerant for air-conditioning and outside air (to reduce temperature of the refrigerant). The water-cooled condenser 4 is disposed beside (on a left side in FIG. 1) the sub-radiator 2 and the air-cooled condenser 3. A bumper reinforcement 9 for collision safety is disposed in front of the sub-radiator 2, the air-cooled condenser 3, and the water-cooled condenser 4.

[0024]The air-cooled condenser 3 includes a core 30, and a pair of a first tank 31 and a second tank 32. In the core 30, tubes and heat-radiation fins are ver...

second embodiment

[0039](Second Embodiment)

[0040]As shown in FIG. 5, in a water-cooled condenser 4A according to the present embodiment, the intermediate connecting member 8 (refrigerant outlet port 8a) is connected with the first tank 31 of the air-cooled condenser 3 slightly above (closely above) (an upper edge of) the bumper reinforcement 9. The air-cooled condenser 3 is disposed above the sub-radiator 2, and the water-cooled condenser 4A is disposed beside (on a left side in FIG. 5) the sub-radiator 2 and the air-cooled condenser 3. Note that, in the present embodiment, components identical or equivalent to those in the first embodiment are labeled by the identical numbers.

[0041]The coolant that has flown out from the sub-radiator 2 flows into the water-cooled condenser 4 through a flexible coolant flow-in pipe 5A disposed at a lower end of the water-cooled condenser 4A. The coolant flows upward in an inner flow passage of the water-cooled condenser 4A, and then flows out from an upper portion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com