Knee prosthesis

a total knee and prosthesis technology, applied in knee joints, ligaments, medical science, etc., can solve the problems of less than perfect total knee prosthesis, more frequent revision surgery, wear and tear of the prosthesis, etc., to prolong the useful life in situ, reduce wear and tear, and effectively replicate the natural knee kinematics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

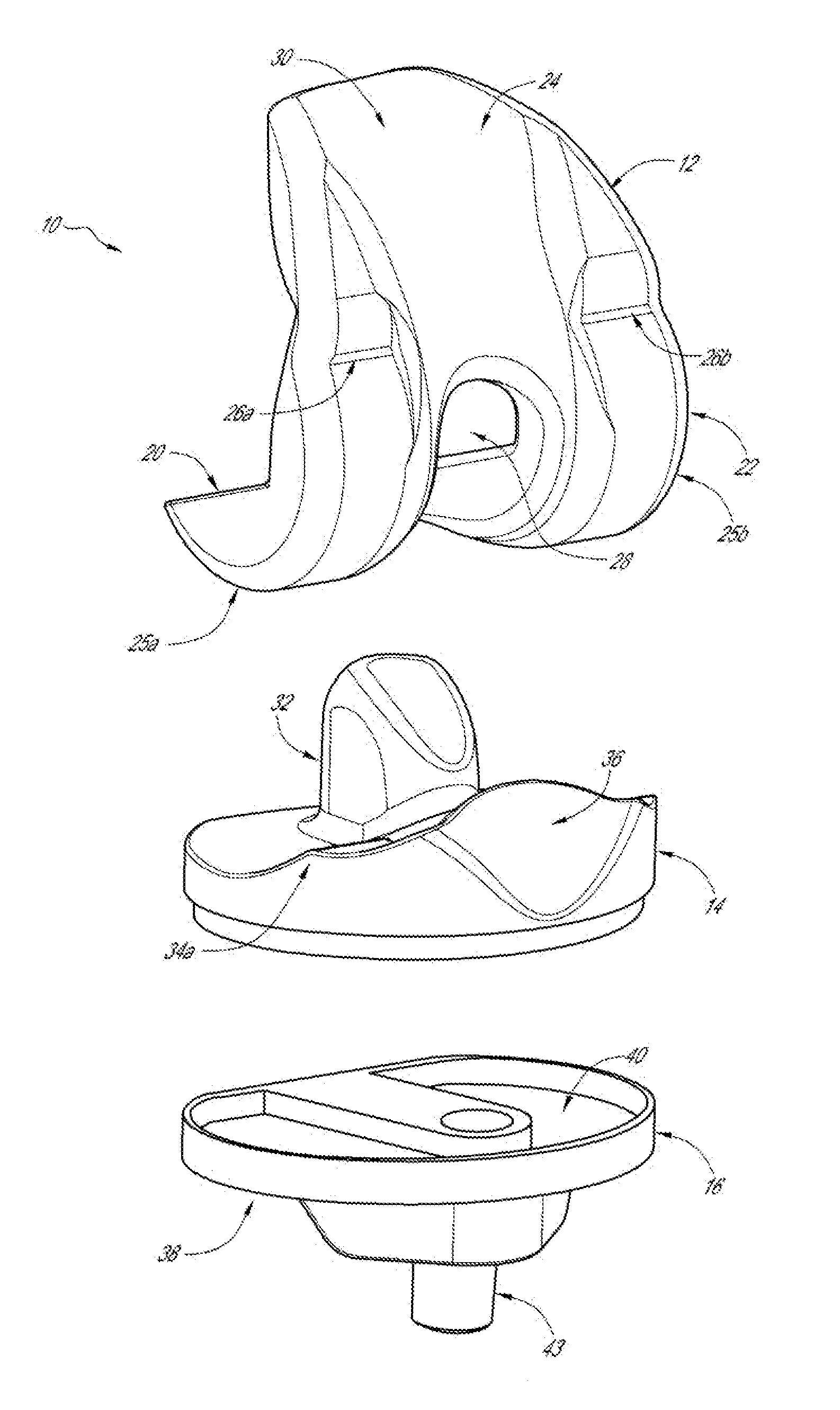

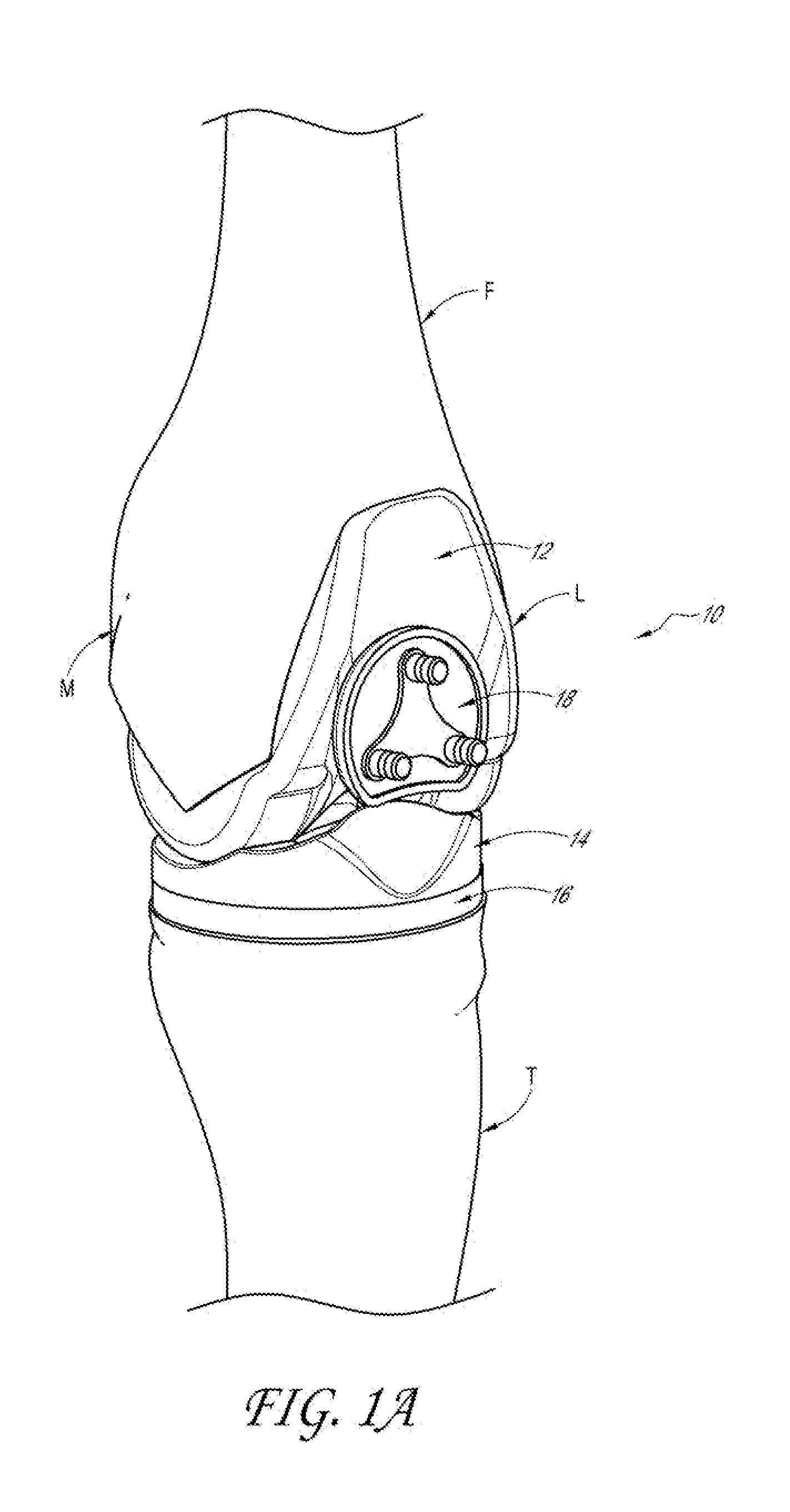

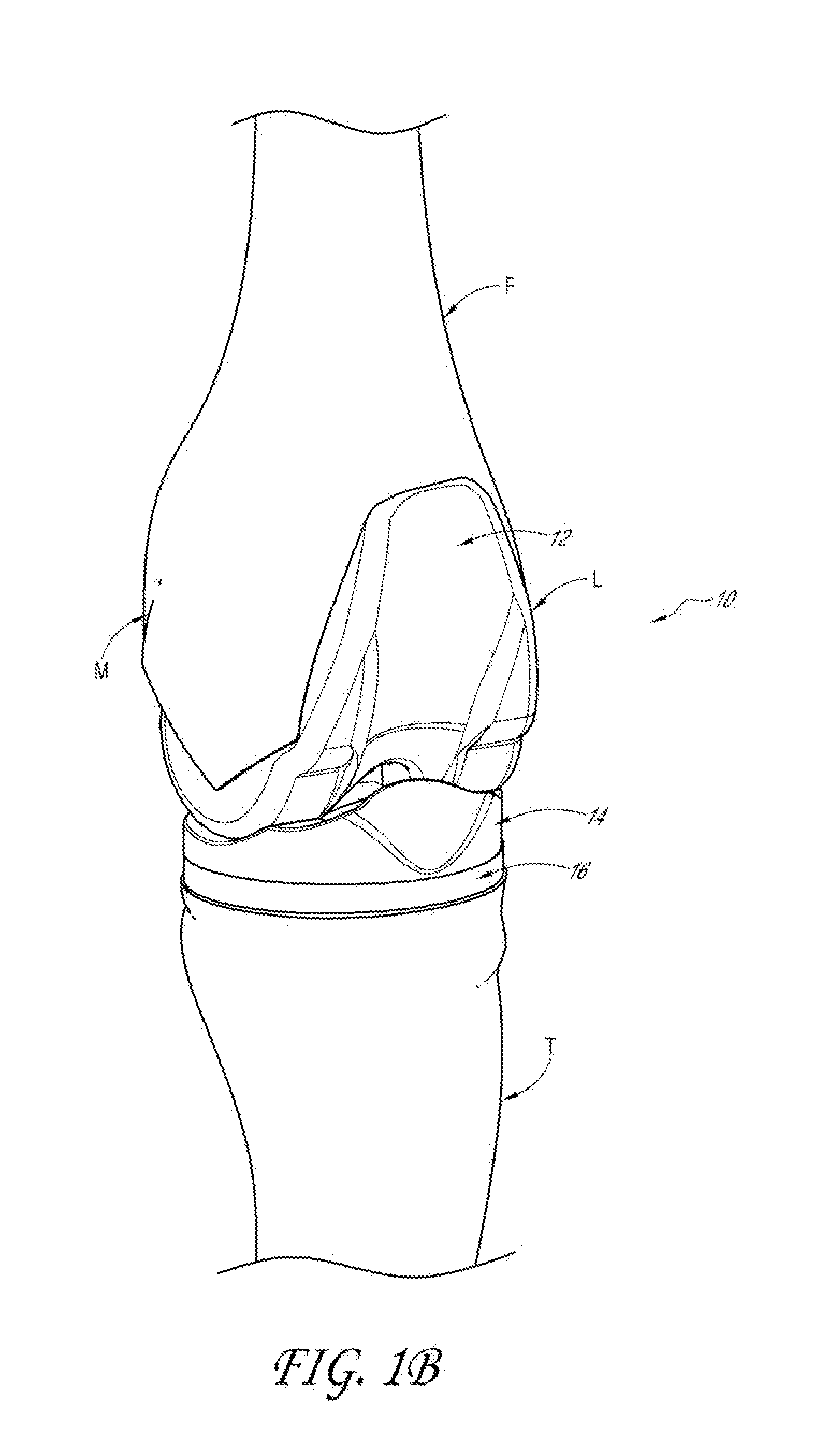

[0043]Referring to FIGS. 1A-1D, in one embodiment, a knee prosthesis system 10 may include a femoral component 12, a meniscal component 14, a tibial component 16, and optionally a patellar component 18. In FIG. 1A, knee prosthesis system 10 is shown with patellar component 18, while in FIGS. 1B-1D, it is shown without patellar component 18. In other embodiments, system 10 may be provided without tibial component 16, for example when meniscal component 14 attaches directly to the cut tibia (not shown). In yet other embodiments, multiple sizes of one or more components may be provided as part of system 10, for example as a kit or suite of operating room tools so that a surgeon can select a desired size of each component or set of components. Generally, therefore, system 10 may include any two or more components of a knee prosthesis as described herein. Although system 10 is typically described below as including femoral 12, meniscal 14 and tibial 16 components, with an optional patell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com