Variable-pitch nozzle for a radial turbine, in particular for an auxiliary power source turbine

a radial turbine and variable pitch technology, which is applied in the direction of rotors, marine propulsion, vessel construction, etc., can solve the problems of loss of efficiency and performance of the turbine taken in isolation, and achieve the effect of limiting performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

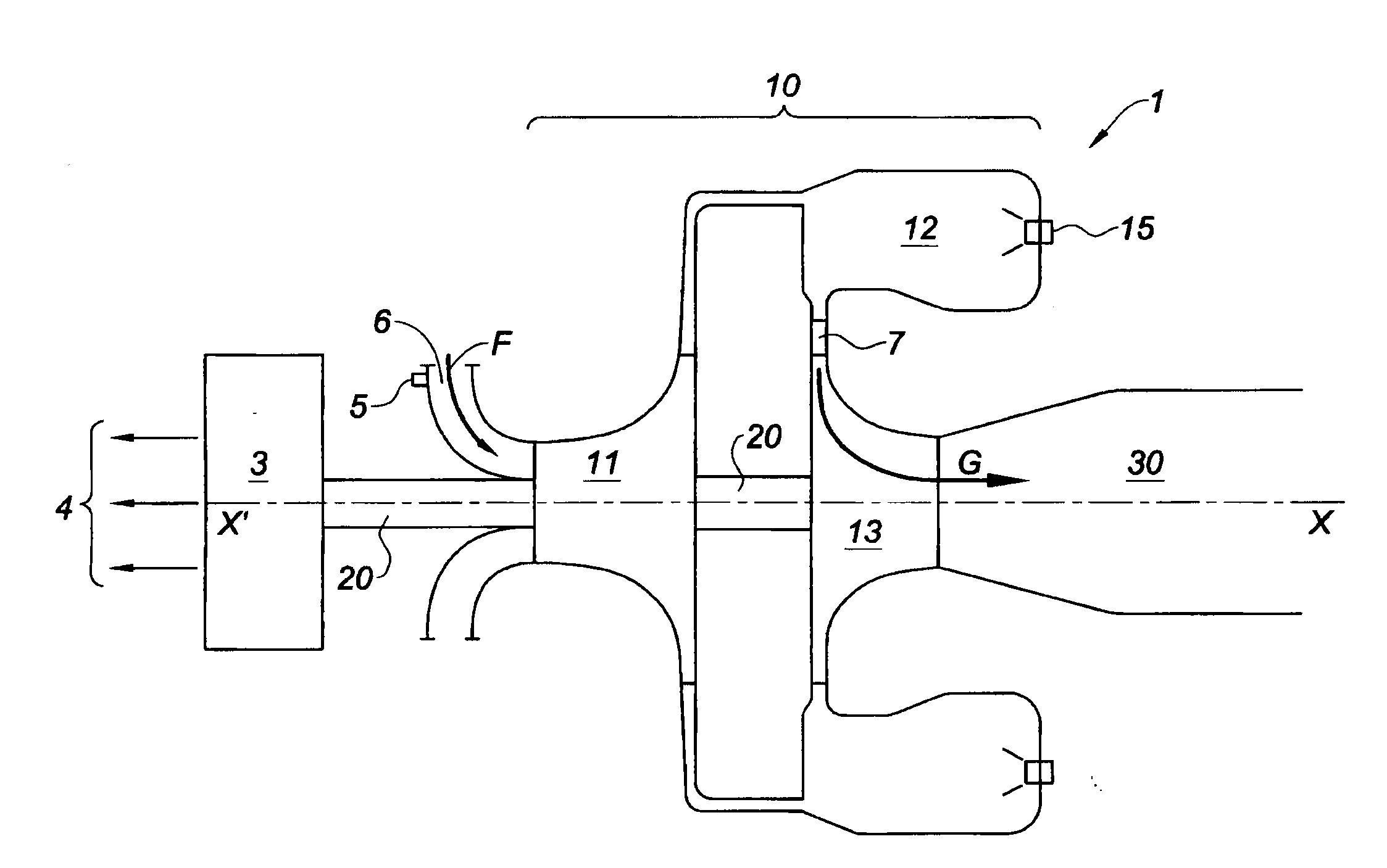

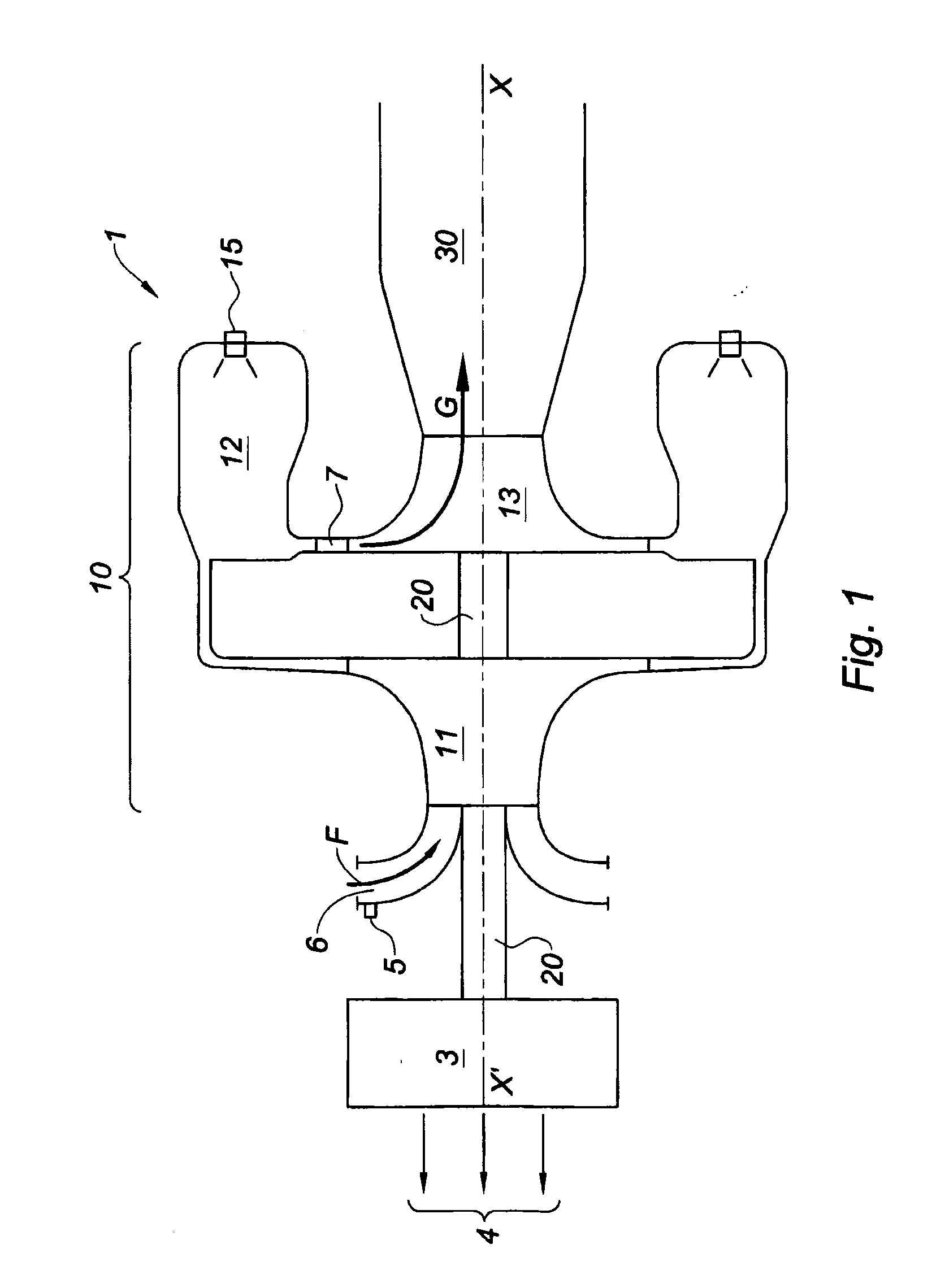

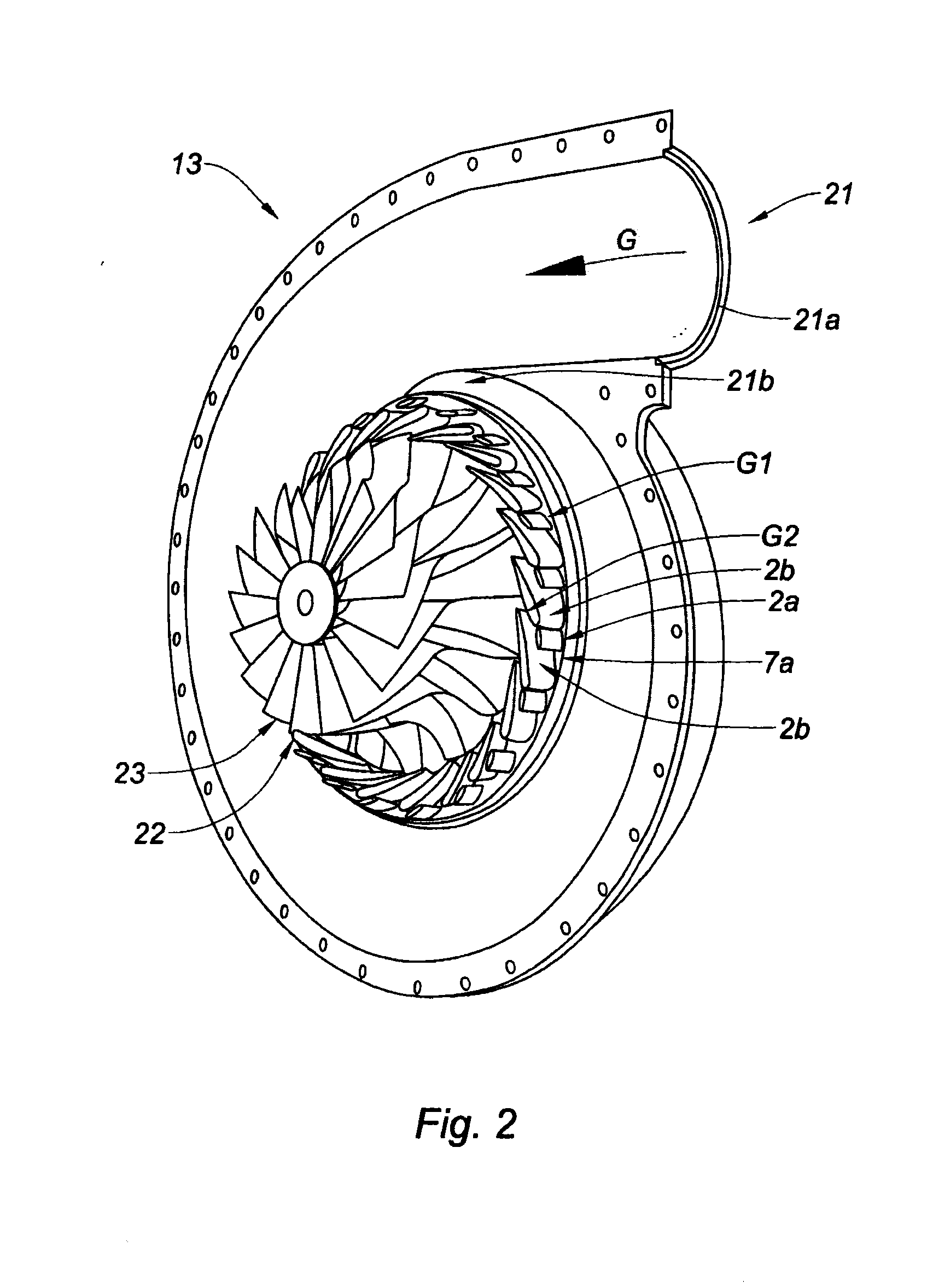

[0023]With reference to the general diagrammatic view in FIG. 1, an example APU 1 comprises a gas generator 10 composed of a centrifugal compressor 11, a combustion chamber 12 and a turbine 13, the turbine driving the compressor in rotation via a transmission shaft 20 about the central axis X′X. The gases leaving the chamber are expanded in the turbine 13, which also provides power to the equipment. The residual gases then leave via an exhaust pipe 30.

[0024]This power is delivered via a through shaft 20 to an accessory gearbox 3 connected to said shaft 20. The accessory gearbox 3 drives, by appropriate speed adaptation means (pinions, reduction gears etc.) the power plant accessories of the APU and auxiliary equipment 4 specific to the functioning of the aircraft: alternator, injector, fuel pump, load compressor, hydraulic pump etc.

[0025]In operation, a throttle governor 5 adjusts the airflow F coming from an air inlet 6, to be compressed in the compressor 11. The compressed air is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com