High-strength aluminum alloy extruded shape exhibiting excellent corrosion resistance, ductility, and hardenability, and method for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

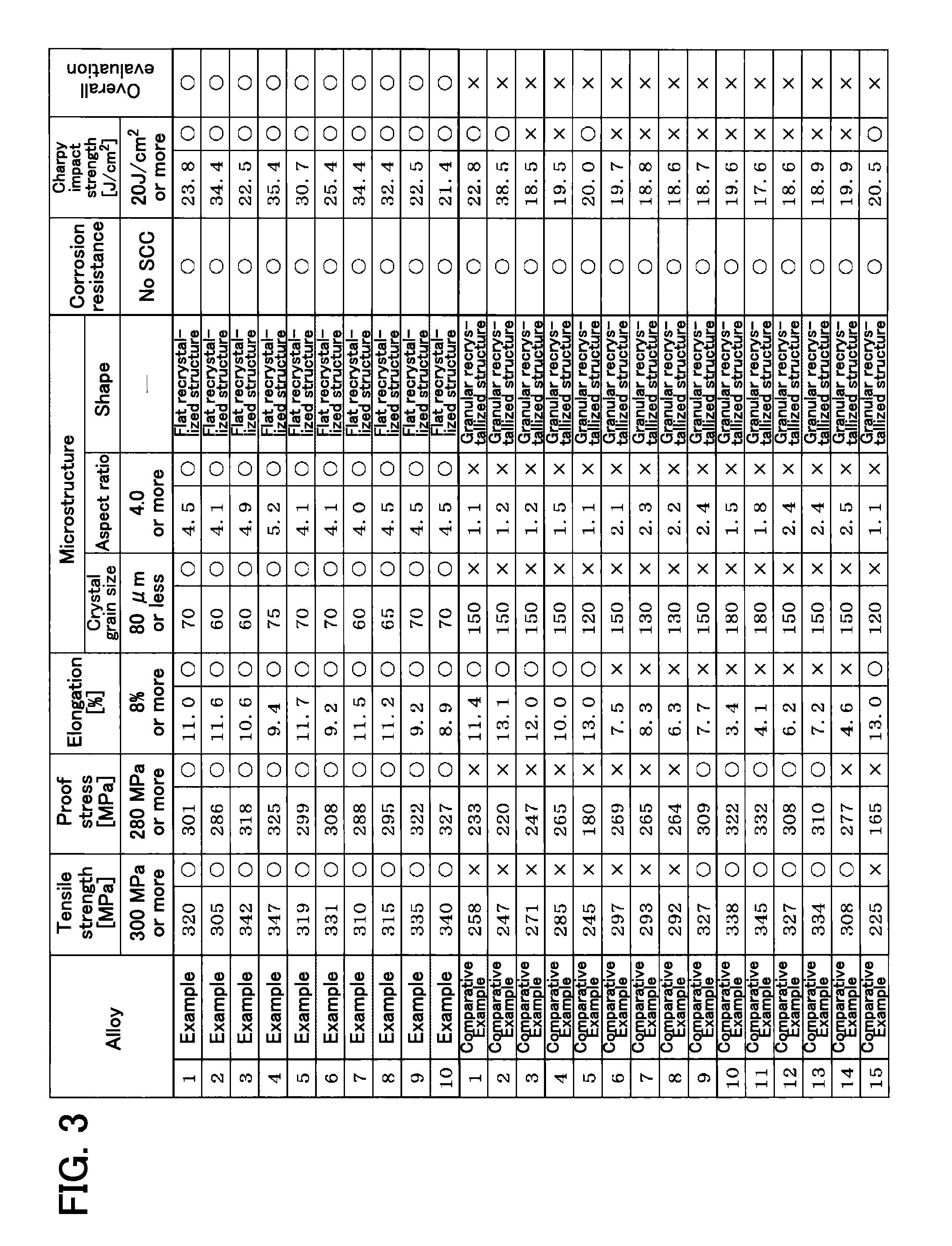

Examples

Embodiment Construction

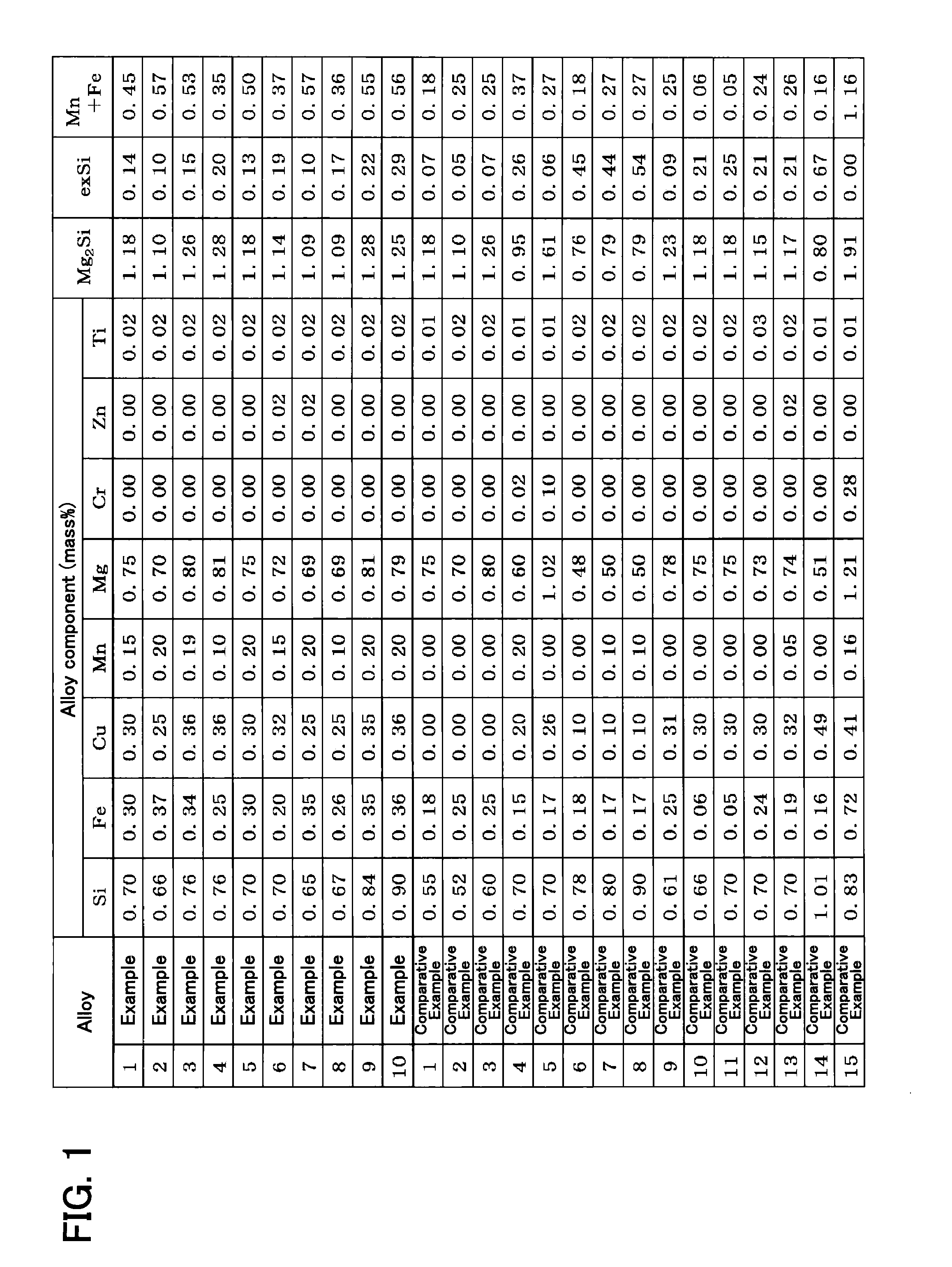

[0048]Billets that differ in chemical composition were cast, extruded, and evaluated as described below.

[0049]A molten metal including the alloy components shown in FIG. 1 was is prepared, and cast at a casting speed 60 mm / min or more to obtain a cylindrical billet having a diameter of 8 inches.

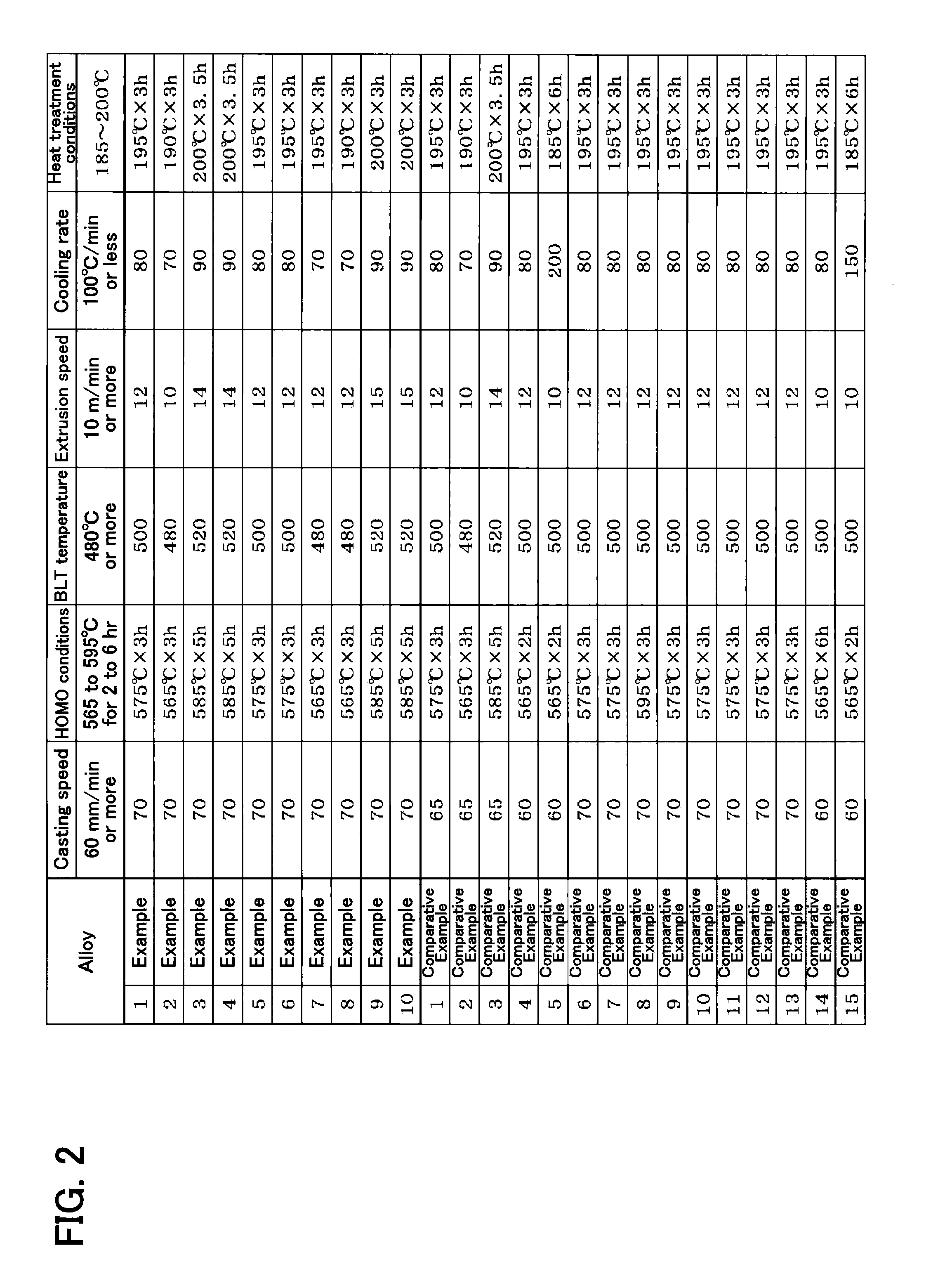

[0050]FIG. 2 shows the subsequent production conditions.

[0051]The cast billet was homogenized at 565 to 595° C. for 2 to 6 hours (see “HOMO conditions”).

[0052]The billet was preheated to 480 to 520° C., and extruded to obtain an extruded shape having a hollow cross-sectional shape (single-hollow cross-sectional shape) (W=50 mm, H=40 mm, t (thickness)=3 mm).

[0053]FIG. 2 shows the extrusion speed and the cooling rate.

[0054]The cooling rate was set to 50 to 100° C. / min in order to achieve press quenching by air-cooling using a fan. Note that the cooling rate was set to 200° C. / min in Comparative Example 5.

[0055]The extruded shape was cooled to room temperature, and subjected to artificial aging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com