Binding element for a building wall structure

a technology for building walls and binding elements, applied in structural elements, building components, pillars, etc., to achieve the effects of good thermal insulation, easy installation of such binding elements, and big toleran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

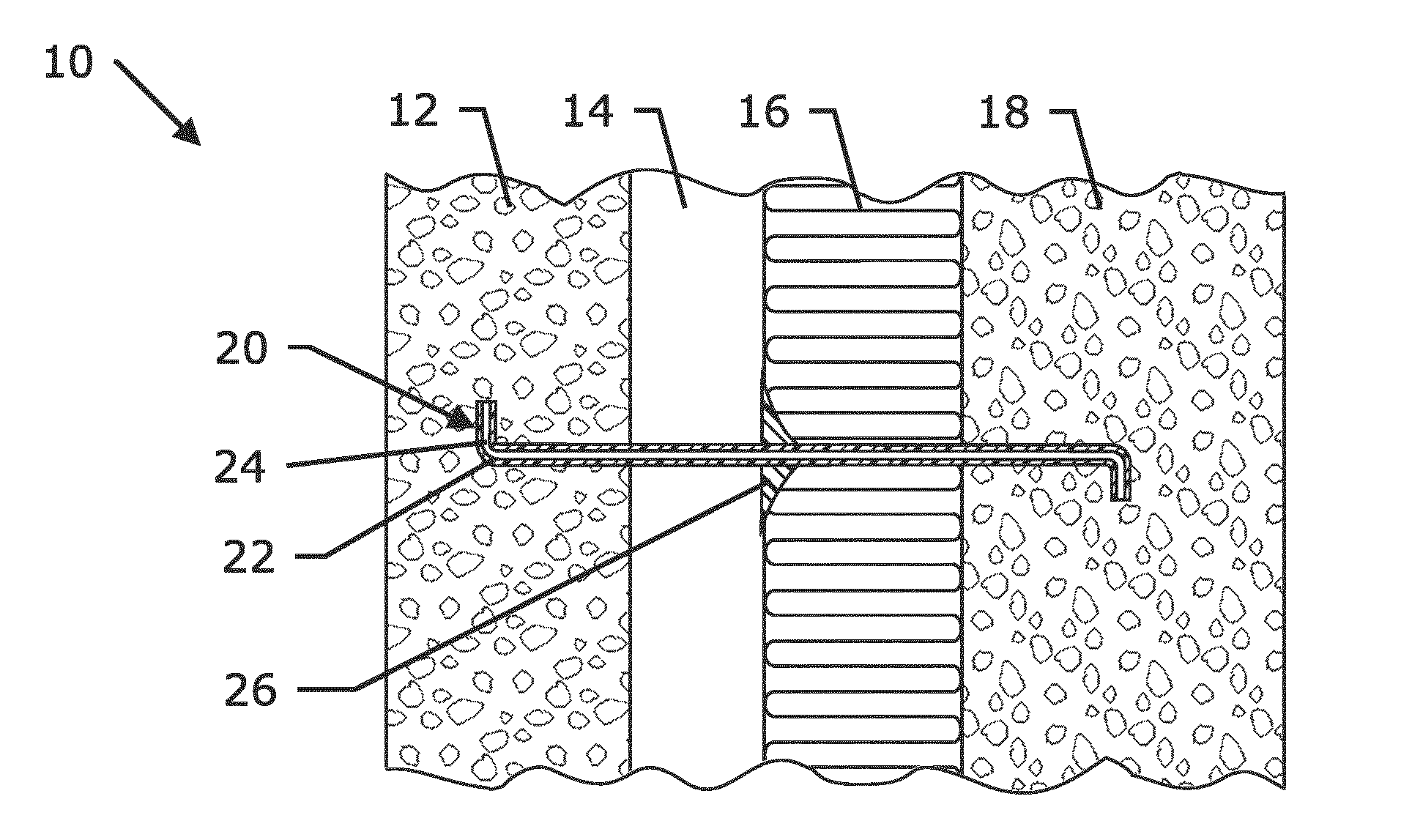

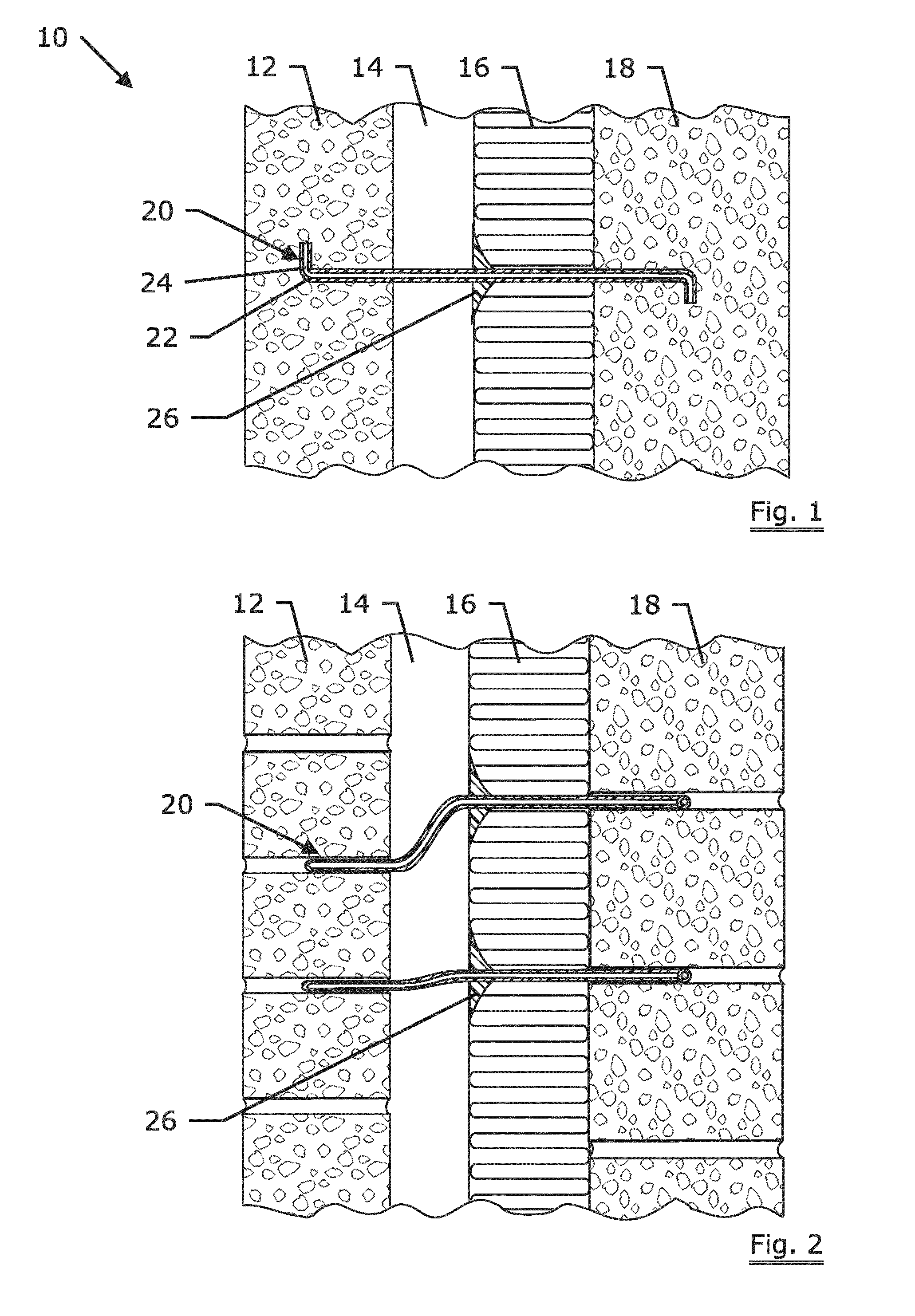

[0011]FIG. 1 depicts a building wall structure of concrete or like composition comprising an inner wall (18), an outer wall (12) spaced from said inner wall and provided with an insulation layer (16) in between, at least one binding element (20) interconnecting said outer wall and inner wall through the insulation layer, the said binding element (20) comprises a elongated steel element (24) preferably having a minimum tensile strength of at least 100 N / mm2 coated with a thermoplastic material (22) of a uniform thickness.

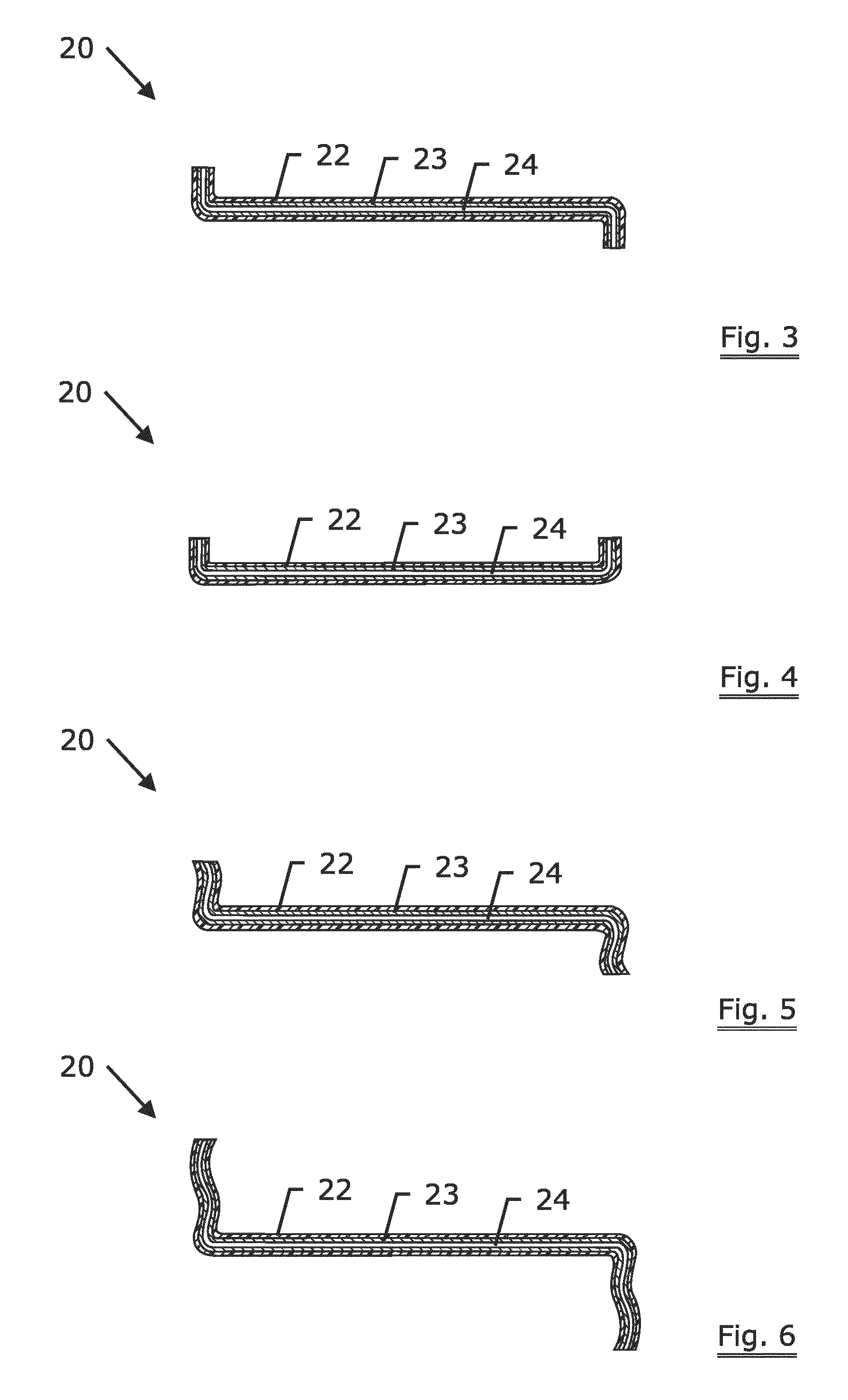

[0012]In one embodiment of the present invention, the elongated steel element (24) is coated with thermoplastic material (22) of a substantially uniform thickness in its entire length and said binding element has two edges and the thermoplastic material is not coated thereon, as shown in FIG. 1 and FIGS. 3 to 6. This configuration can significantly simplify the production process and thus reduce the cost of the binding element. A bundle of steel wire can be first con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com