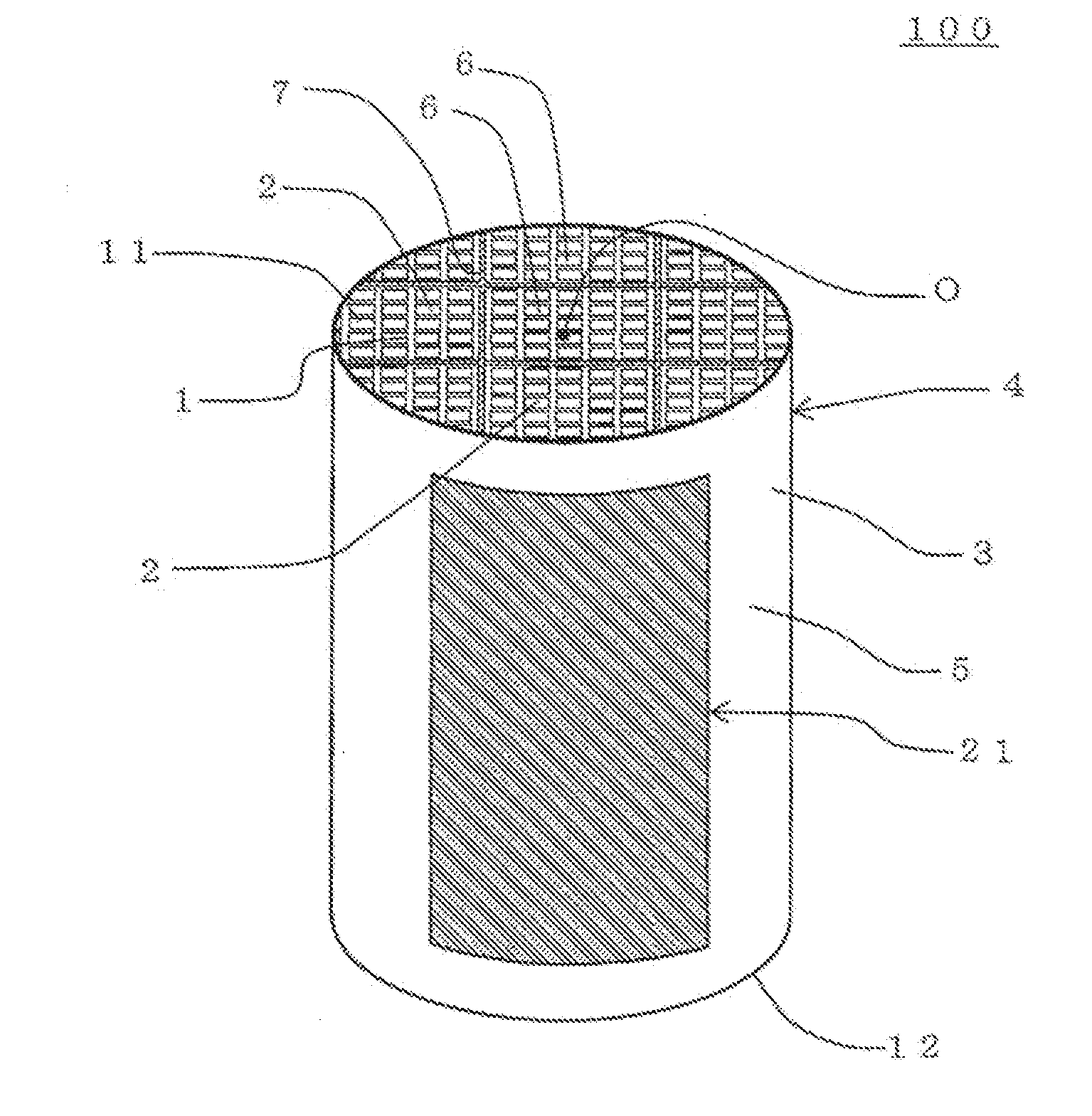

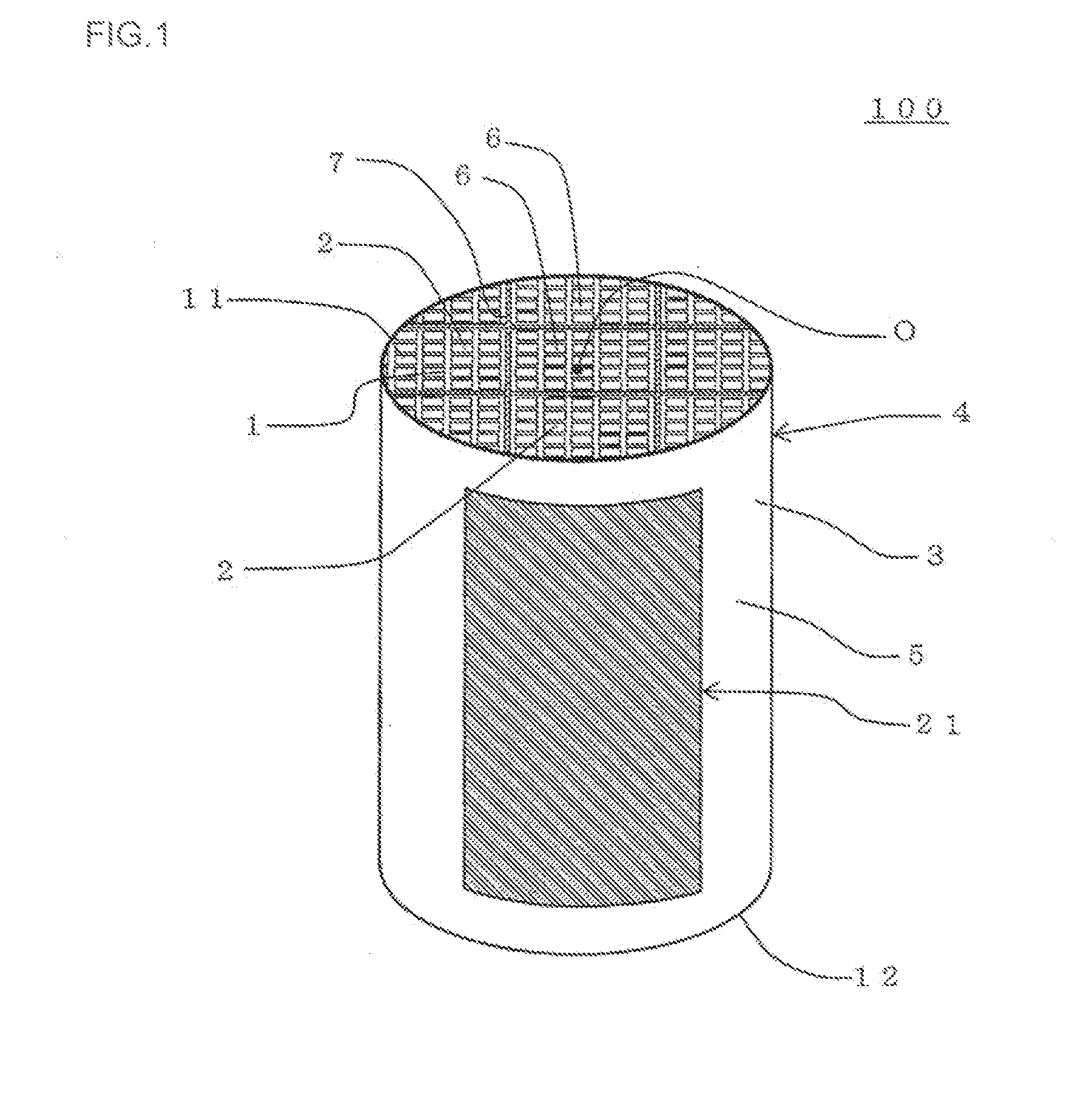

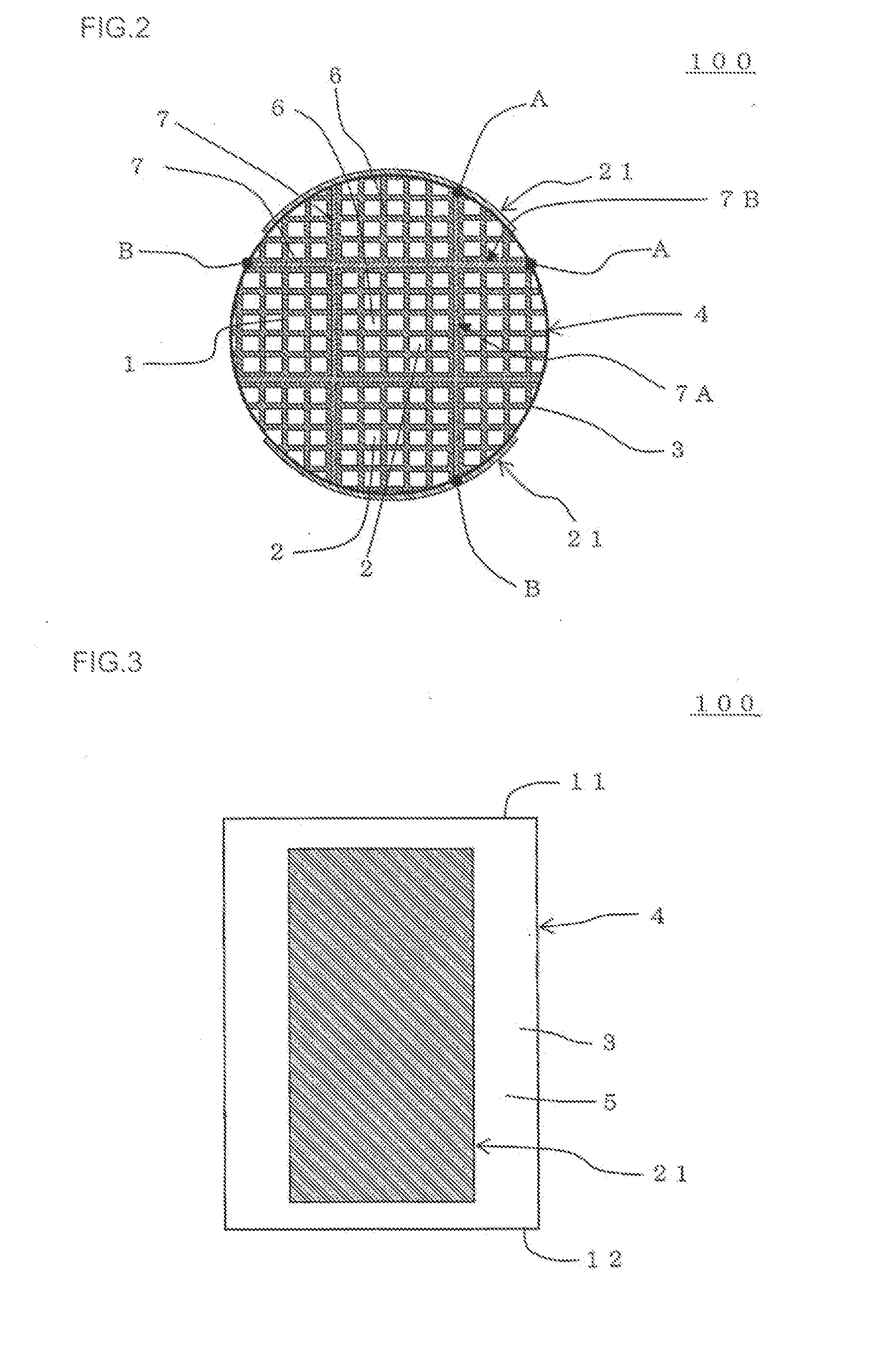

Honeycomb structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0167]First, there was prepared a honeycomb forming raw material to prepare portions of honeycomb segments of a honeycomb segment bonded body. The honeycomb forming raw material was prepared by kneading 6 kg of silicon powder of 5 μm, 14 kg of silicon carbide powder of 30 μm, 1 kg of cordierite powder of 4 μm, 1.6 kg of methylcellulose, and 8 kg of water with a kneader.

[0168]Next, the obtained honeycomb forming raw material was kneaded in vacuum to obtain a kneaded material, and the obtained kneaded material was extruded into a honeycomb form, to obtain a honeycomb formed body. Next, the obtained honeycomb formed body was dried at 120° C. to obtain a honeycomb dried body.

[0169]Next, an electrode member forming raw material to form electrode members was prepared. The electrode member forming raw material was prepared by kneading silicon powder having an average particle diameter of 5 μm, silicon carbide powder having an average particle diameter of 50 μm, cordierite powder having an ...

example 2

[0179]The procedures of Example 1 were repeated except that a bonding material was prepared as follows, to prepare a honeycomb structure. Specifically, 84 g of silicon powder having an average particle diameter of 5 μm (a density of 2.33 g / cm3) was used. 103 g of silicon carbide powder having an average particle diameter of 43 μm (a density of 3.17 g / cm3) was used. 4 g of cordierite powder having an average particle diameter of 4 μm (a density of 2.65 g / cm3) was used. 12 g of alumina fibers (a density of 3.28 g / cm3) of Al2O3 / SiO2=80 / 20 (a mass ratio) were used. 10 g of resin powder (a density of 0.02 g / cm3) having an average particle diameter of 100 μm was used. 1 g of methylcellulose, 20 g of glycerin and 110 g of water were used. These materials were kneaded by a mixer, to prepare the bonding material. An average fiber diameter of inorganic fibers (i.e., alumina fibers) made of an oxide to be included in a bonding layer of the honeycomb structure of Example 2 was 8 μm and an avera...

example 3

[0180]The procedures of Example 1 were repeated except that a bonding material was prepared as follows, to prepare a honeycomb structure. Specifically, 82 g of silicon powder having an average particle diameter of 5 μm (a density of 2.33 g / cm3) was used. 78 g of silicon carbide powder having an average particle diameter of 16 μm (a density of 3.17 g / cm3) was used. 9 g of cordierite powder having an average particle diameter of 4 μm (a density of 2.65 g / cm3) was used. 35 g of alumina fibers (a density of 3.28 g / cm3) of Al2O3 / SiO2=80 / 20 (a mass ratio) were used. 10 g of resin powder (a density of 0.02 g / cm3) having an average particle diameter of 100 μm was used. 1 g of methylcellulose, 20 g of glycerin and 110 g of water were used. These materials were kneaded by a mixer, to prepare the bonding material. An average fiber diameter of inorganic fibers (i.e., alumina fibers) made of an oxide included in a bonding layer of the honeycomb structure of Example 3 was 8 μm and an average fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com